2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:34

Organization of an efficient and reliable air ventilation system at the enterprise is the first step towards creating comfortable working conditions for employees. Ventilation of premises can be carried out in a natural and forced way. In the second case, industrial fans are required for operation, the technical characteristics of which will determine the efficiency of the entire ventilation system.

Key features of fans

Fans are electromechanical devices designed to move air masses through air ducts, direct supply or intake of oxygen from rooms. Forced air circulation in the building occurs by creating a pressure difference between the inlet and outlet wells with installed equipment.

The efficiency of the fan does not always depend on its power. In most casesthe following technical characteristics of industrial fans are decisive:

- air consumption - the volume of air masses moved for a given period of time (m3/h);

- total pressure - determines the speed of air flow (Pa);

- rotational speed - shows how quickly the air circulation will start (rpm);

- power consumption - the amount of energy spent during operation (kW);

- produced sound level - has a direct impact on the degree of noise discomfort (DB).

The last defining parameter is the coefficient of performance (COP), which shows how efficiently the fan works. When determining this parameter, energy losses due to friction and volume losses are taken into account.

Features of industrial fans

Depending on the indicators of the presented technical characteristics of industrial fans, the efficiency of the entire ventilation system is determined. Devices of this category are used where it is necessary to supply or remove large volumes of air from rooms - in apartment buildings, hotels, shopping centers.

Productivity of industrial plants can reach 75 thousand cubic meters per hour. Three types of fans are most widely used:

- axial - installed in small buildings and small businesses, have low productivity;

- duct - used for effective ventilation of a large number of enclosed spaces;

- centrifugal - the most powerful of the presented installations, used at industrial facilities;

Technical characteristics of industrial fans must correspond to the functional purpose of the building. The right choice of equipment, compliance with the mode and operating conditions will ensure effective ventilation and the creation of a comfortable microclimate for work.

Axial fans

Axial devices are used in stationary ventilation and air heating systems. Their main advantage is a simple design, which leads to durability and maintainability. They are ideal for temperate and subtropical climates.

Productivity of axial industrial fans varies from 1, 2 to 72,000 m3/h. In this case, the power of installations is measured in units of kilowatts. However, the level of noise produced by them is quite high. It starts rising from 75 dBA, which corresponds to a lively conversation of a noisy group of friends.

Duct fans

Duct devices are the most common. They are used for ventilation of office premises, hospitals, schools, kindergartens and other municipal and administrative buildings. The noise level produced by them is less than 75 dBA, which, when dissipated, does not exceed 58 dBA, which complies with European standards for Class A office space.

Most devices have variable speed blades. The sizeequipment does not exceed 32 cm, the rated power varies from 42 to 290 watts. Inline fans are most beneficial for office space.

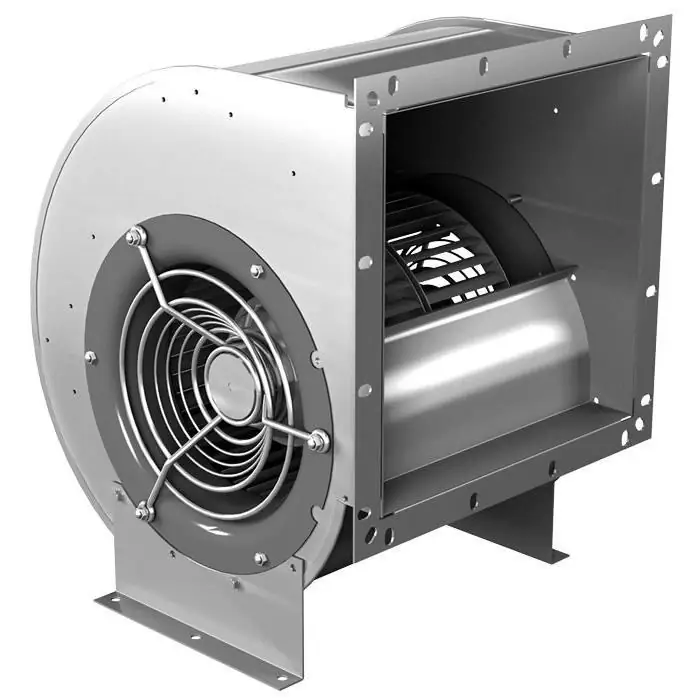

Centrifugal fans

The case of centrifugal devices is made in the form of a spiral, which gives additional centrifugal force to the air flow when it is sucked from the ventilation well. Therefore, such devices are used as industrial exhaust fans. Centrifugal units are capable of creating pressure in the system up to 10 kPa and accelerating air flows up to 200 m/s.

A wide range of device performance allows you to choose the best option for each specific case. However, such fans are quite bulky and often require a separate room for installation. Only developed enterprises can afford their installation.

Recommended:

Hydraulic stations for presses: types, specifications, purpose and practical application

Hydraulics is one of the oldest mechanisms in the operation of power equipment. The simplest representative of this type of units is a press. With its help, large compressive forces are provided in various industries with minimal organizational and operational costs. The quality of operation of the device will depend on which hydraulic station is used for the press - whether it meets the target design in terms of working properties and whether it is able to maintain sufficient force

Industrial pipes: types, characteristics, purpose

Industrial pipe is a tubular section or hollow cylinder, but not necessarily round. It is used more often for transporting substances, liquids, gases, suspensions, powders and small solids. Various types of pipes are used in industry, they differ not only in diameter and material, but also in the method of installation. Their classification is extensive, but to understand it, you should study the types of pipes used in various industries

Household fans - overview, models and specifications

Household fans: description, features, modifications, photos. Household fans: overview, types, models, specifications. How to choose the right household fan?

Protection devices: purpose, types, classification, specifications, installation, features of operation, settings and repair

Protection devices are currently in operation almost everywhere. They are designed to protect both electrical networks and electrical equipment, various machines, etc. It is very important to properly install and follow the operating rules so that the devices themselves do not cause a fire, explosion, etc

Industrial lamp: types, characteristics, purpose

The article is devoted to industrial lamps. The characteristics, varieties, nuances of installation and the purpose of this lighting equipment are considered