2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:26

High-tech modern welding is carried out in accordance with generally accepted quality criteria. The final product of the work is welding seams, the types and designations of which are classified, described and divided according to quality and methods of execution.

What is a weld

The terms "weld" and "weld" often mean the same thing, but some sources share both formulations.

According to the simplest designation, a weld is an integral connection of parts by welding.

A more complex definition is related to the physics of the process: a weld is a section of a crystallized or deformed substance that combines several parts. Welds and seams, one way or another, are perceived as the same definition.

Classification

Types and designations of welds are determined by their features. The classification of seams is based on the range of their application. According to the external parameter, the seams are divided into:

- Convex, reinforced.

- Concave, withloose design.

- Flat.

Depending on the type of execution, the seams are divided into one-sided and double-sided, according to the number of passes by the electrode - into single-pass and double-pass. There are also single-layer and two-layer methods of penetration.

The length of the seams are classified into:

- Single-sided solid.

- Single-sided intermittent.

- Point. Typical for contact electric cooking.

- Bilateral chain.

- Double-sided checkerboard pattern.

By spatial arrangement they are divided into:

- Bottom horizontal.

- Ceiling vertical.

- In the boat.

- Semi-ceiling.

- Semi-horizontal.

- Semi-vertical.

According to the force impact vector they are classified into:

- Flanking, or longitudinal. The force is applied parallel to the penetration.

- Transverse. The force is applied perpendicularly.

- Combined. Combines all varieties.

- Slanting. The interaction is carried out at an angle.

The designation of welding seams according to GOST, depending on the functions and purpose, is divided into strong, tight and strong. In width, a thread seam is distinguished, the value of which does not exceed the diameter of the electrode rod, and a broadened one, which is performed by vibrations in the transverse direction during welding.

According to GOST, a strict designation of the types of welds and joints is described. Information about the type of fastening and the method of its implementation is reflected in special icons,used in drawing up drawings.

Types of welds

The type of weld to be used depends on the materials, their thickness and design features. Understanding the specifics of welding parts and avoiding defects in work is possible only if you have the appropriate theoretical background. The reason for the weak mechanical resistance of the joints in most cases is insufficient welding of the joints. Proper quality and strength of the seams are achieved by choosing the right types and modes of welding. The training of welders includes not only a practical, but also a theoretical part - the study of norms and rules, symbols for welding seams, features of the equipment used. Knowing the basic principles of using certain fasteners and welding operations allows you to get a durable and strong connection.

Butt welds

Type of welding joints, most often used on pipes, sheet structures and end sections. Formed with minimal time, effort and materials. Such butt fasteners have their own characteristics: thin sheets of metal are welded without beveled edges.

Greater joints require pre-treatment, which consists of bevelling for greater depth of penetration. Such preliminary preparation is carried out for metal products, whose thickness is in the range of 8-12 millimeters. Thicker metals are combined by double-sided welding with beveled edges. Butt welds are most often performed inhorizontal plane.

Tee seams

The designation of T-type welding seams is made in the form of the letter "T". The width of the weld depends on the thickness of the objects to be combined, the characteristics of the bonding affect how the connection will be - one-sided or two-sided.

The electrode is held at an angle of 60 degrees when working with metal parts of different thicknesses. The welding process is simplified if tacks or the "boat" method are used - it reduces the number of undercuts. The imposition of a tee seam is carried out in one pass. For this type, automatic electric welding machines are widely used.

Lap seams

Seams used for welding sheet metals up to 12 millimeters thick. The materials to be joined are overlapped and welded on both sides along the joints. The internal part of the structure to be welded must be insulated from moisture. Additional welding around the perimeter is carried out in order to strengthen the bond.

The formation of a connecting joint by means of an overlap seam is carried out between the surface of one product and the end face of another. This welding method significantly increases the consumption of materials, which is taken into account in advance. Before starting work, the sheets of metal are aligned and carefully pressed against each other.

Angular

Designation of welds performed at a certain angle to each other. A characteristic feature isproviding better penetration through the use of pre-bevels. This not only increases the depth of the weld, but also increases the reliability of the entire structure. The strength is enhanced, among other things, due to the two-sided welding of metal products without gaps in the edges. Such electric welds are characterized by a large amount of deposited metal.

Ceiling joints

One of the most difficult electric welding jobs to perform due to the location of the seam above the welder. It is created by the minimum strength of the electric current by an intermittent welding seam. The designation of ceiling and vertical joints in the instructions warns of the complexity of the work and the need for certain skills of the welder to achieve maximum quality. Ceiling seams are resorted to in conditions where it is not possible to displace the structures to be welded: work with pipes, ceiling channels and beams at construction sites, all kinds of metal structures. The specifics and nuances of ceiling seams are mastered only in practice.

Cleaning completed seams

Welded seams after completion of work have an uneven texture, protruding above the surface and leaving behind drops of metal, traces of slag and scale. All this is removed, and the process itself is called stripping.

Is carried out in several stages:

- Dross is knocked off with a chisel or hammer.

- The section with the seam is processed by the grinder.

- Sometimes tinning is carried out - appliedthin layer of molten tin.

Marriage and possible defects

Most often in the work of welders there is a curved seam with uneven filling. Such a defect is possible due to uneven electrode guidance. It is eliminated only with a set of experience as a welder.

The second most common defect is the wrong choice of arc length or current strength, which leads to uneven filling or "undercuts". Depending on the type of defect, either the aesthetics of the seams or their strength may suffer.

Lack of fusion

Under the lack of fusion in the rules for designating welds and other instructions, they understand insufficient filling of the joint of parts with metal. Appears in the following cases:

- Missing or poor quality edging materials.

- Low amperage.

- Electrode speed too high.

Cut and burn through

Undercut - an unnecessary groove located along the seam. The defect occurs due to the arc of great length. Prevented by shortening the arc length or setting a higher current.

Burn through - a hole in the seam - occurs for several reasons:

- Large gap between metal edges.

- High current.

- Slow electrode movement.

Sagging and pores are small holes that appear in large numbers and negatively affect the strength of the finished seam. There may be several reasons for their appearance:

- Traces of rust and dirt on the metal.

- Oxygen hitting the molten metal when working in a draft.

- Poor quality metal edging.

- Poor quality electrodes.

- Using filler wire.

When the integrity of the seams is broken, cracks occur. Occur after cooling of the molten metal and portend the destruction of the connection. The only way to save the situation is by digesting the suture or by removing it completely and then applying a new one.

Tips for cooking different types of compounds

It is not difficult to learn how to apply high-quality and durable seams on your own: for this purpose, a large amount of professional literature is offered, which indicates not only cooking tips, but also the ratio of Russian and international designations of welding seams with other nuances. Each type of seam has its own subtleties that need to be mastered.

Beginners are advised to start with electric arc welding and proper preparation of the necessary tools.

The following equipment is being prepared for electric arc welding:

- Welding equipment.

- Electrodes of correct diameter.

- Hammer or chisel for cleaning seams.

- Metal brush for cleaning the welded area.

- Special light filter and mask.

Special and at the same time simple requirements are imposed on the welder's clothing: it must be dense, it is obligatory - with gloves and long sleeves. When working with an old weldingequipment, it is desirable to use a rectifier and a transformer.

Recommended:

Welding technique: basic concepts, rules and possible mistakes

Hot welding is one of the most common assembly processes used in construction and industry. It is used both in high-tech operations for the assembly of equipment, and in the simplest typical work when connecting load-bearing structures. In each case, its own welding technique is used, which is optimally suited for operational parameters, working conditions and requirements for the result

Thermite welding: technology. The practice of thermite welding in everyday life and in the electrical industry

The article is devoted to thermite welding technology. The features of this method, the equipment used, the nuances of use, etc. are considered

Flux for welding: purpose, types of welding, flux composition, rules of use, GOST requirements, pros and cons of application

The quality of the weld is determined not only by the ability of the master to organize the arc correctly, but also by the special protection of the working area from external influences. The main enemy on the way to creating a strong and durable metal connection is the natural air environment. The weld is isolated from oxygen by a flux for welding, but this is not only its task

Graphic designation of the ruble. International designation of the ruble

The graphic designation of the ruble has the format of the Cyrillic letter "R", which is crossed out at the bottom of the leg. This symbol, developed over the course of 6 years, embodies the reliability of the Russian currency

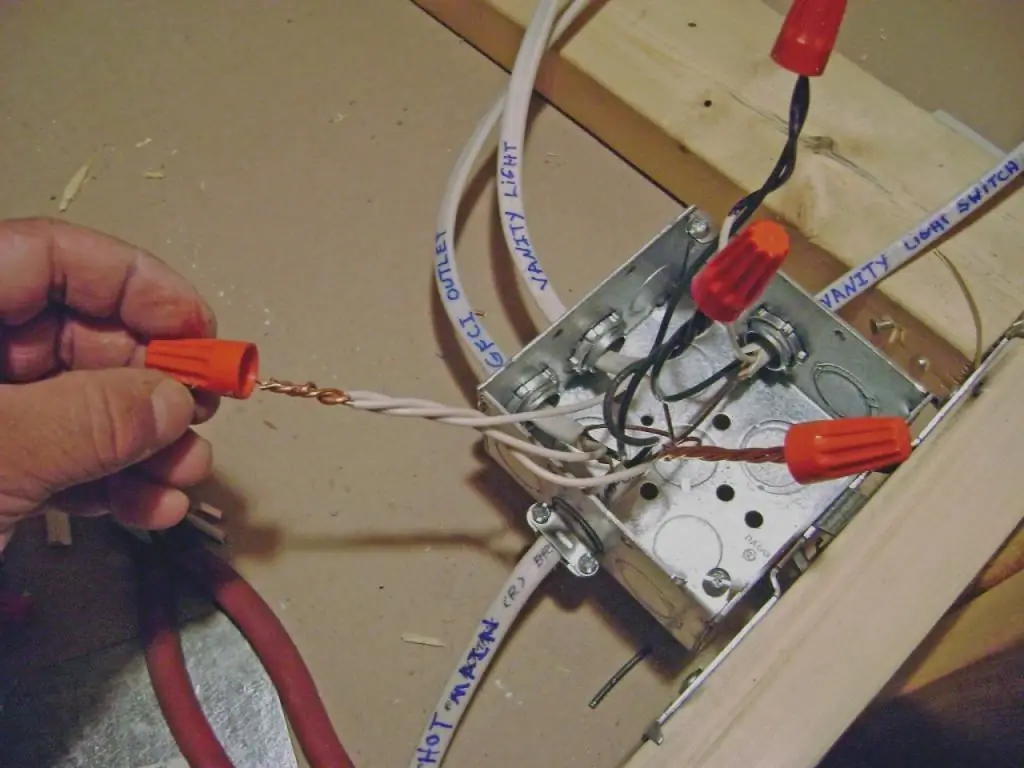

Welding wires in a junction box: step by step instructions, rules, tips and tricks

Features of welding wires in a junction box with your own hands. The main advantages of the welding connection of wires and the technology of the welding process. Electrodes that are used in the welding of copper conductors. Apparatus for welding. DIY step-by-step instructions for making a welding machine