2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:26

Industrial marker - a writing tool for drawing information on a variety of surfaces. In this case, the surface can be wood, glass, stone, metal, leather, painted materials and even rust. The requirements for such a marker are very specific.

What is this?

Unlike conventional markers used in the office, a special one can write not only on paper, but also on any materials. Use such a tool for marking products in production. Often the field for the inscription is oiled, stained and red-hot. However, a special surface marker can do the job on any difficult surface.

What makes it possible to call a marker industrial? This is, first of all, the durability of the inscriptions. Information should not disappear from mechanical abrasion, must withstand exposure to moisture, dirt, oily substances and ultraviolet radiation.

Another important indicator that the tool is suitable for use in difficult conditions is the ease of application to uneven, wet and dirtysurface.

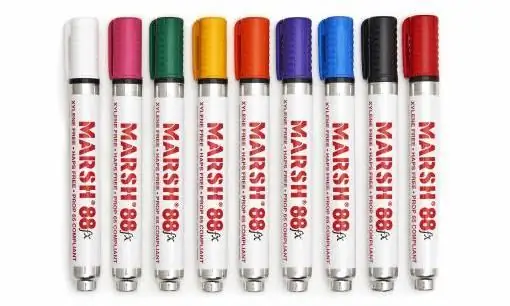

High and low temperatures should also not be a barrier to writing with an industrial marker. At the same time, products with a filler and a core of various types and colors are used to solve specific problems. Today, industrial markers are produced in white and black, multi-colored and imitating a metallic coating.

Markers for specialized jobs are used by: builders, metallurgists, carpenters, sculptors, artists, mechanics, electricians, as well as representatives of many other professions. In household use, such an item will also not be superfluous. It will come in handy during major repairs and small household work.

What is it made of?

Industrial marker consists of a rod, filler, body and protective cap. Depending on the task set for a certain type of tool, each element can be made of different materials.

The stylus, which acts as a stylus, is made of a porous material that can absorb and conduct moisture, which in this case is ink.

The rod can be crafted:

- oval-shaped;

- round - bullet-shaped;

- in wedge-shaped, angled version;

- in a special horseshoe shape for dyeing wires.

The length of the stylus is usually 4mm. Sometimes a metal ball is used as a rod, as in a regular ballpen.

Filler for industrial marker can be:

- water ink;

- benzene ink;

- liquid or solid paint.

Fillers are divided by durability into permanent and non-permanent. If the inscription needs to be preserved for a long time, then it is worth using a permanent marker. If necessary, traces of its use can be washed off with alcohol or a plastic stationery eraser.

Main tasks and properties of the marker

Marking with an industrial writing instrument is adapted to the aggressive environment of production shops. Inscriptions with such markers withstand the effects of solvents and acids, intense mechanical abrasion, and are thermally stable.

When marking industrial products with a marker, it is necessary to achieve the effect of maximum visibility, durability and at the same time the ability to correct or delete what is written. The task assigned to the writing instrument will be performed perfectly, provided that its type meets all the conditions.

Written with a quality industrial graphics marker that dries quickly and won't crack on vertical surfaces.

A good tool can go from writing on hot metal to marking plastic and wet wood without loss of quality.

How to choose the right one

The marker is chosen for a specific task. For a home tool case, you can purchase a colored permanent marker in black, red or bright green. Suchthe tool will be universal for marking walls, wires, concrete blocks, wooden structures, marking metal and plastic parts.

In production, everything is more complicated. First, we determine the future "field of activity" of the marker for industrial graphics: industrial woodworking, metallurgy, medicine, construction, or something else. Next, you need to decide on the contact material: metal, wood, fabric, glass and more. Then we formulate the main qualities of the surface: rusty, oiled, rough. Desired properties of the marker: waterproof, heat resistant, for marking fabric or rubber.

After fixing all the requirements, you can purchase a marker designed specifically for your task. The color of the tool should contrast with the surface. The black industrial marker will be perfectly visible on smooth light surfaces.

For various purposes

The filler of the marker and its writing unit differ depending on the type of activity and the scope of the tool.

For inscriptions on wood, use a tool filled with opaque mastic, which is perfectly absorbed into fibrous wood.

For permanent marking of smooth glass, plastic and metal surfaces, a permanent waterproof marker with ink filler is used. Such inscriptions can be removed with an organic solvent.

If it's not so much durability that matters, but the brightness of color and decorative effect, then you should turn to a chalk industrial marker. This tool is filled with liquid chalk of very bright and pure colors. The chalk marker has several features: drying time - several minutes, resistance to a humid environment, washable with a damp sponge.

Plastic surgeons, dermatologists and radiologists use non-toxic medical markers to mark a patient's skin. Traces of such a tool are harmless and washed off with water.

Marking difficult materials: oily, rusty, rough and permanently wet surfaces is a challenge for hard paint filler. There is no rod as a separate element in such a marker. Its role is played by the paint pressed in the form of a tip. These types of markers are called "marker paste".

Colorful and varnish markers

Materials requiring marking can be of any color. The main difficulty is presented by dark or transparent surfaces. To write on a black surface, use gold, silver or white writing instruments.

White industrial graphic marker will be clearly visible on smooth transparent surfaces, and on matte and dark uneven materials.

For the application of indelible clear inscriptions, the so-called marker varnish is used. The industrial varnish marker writes with a very bright, opaque and quick-drying ink with a glossy effect.

Rules of application

The use of a marker, like any tool, must be careful and accurate. To save the marker itself, you need to follow a few simple steps.rules:

- the cap must be tightly twisted after each use to avoid drying out of the filler;

- after applying the inscription, the marker must be put back in place - in a pocket or in a work case. A tool left on a work machine can not only be deformed by itself, but can also lead to unpleasant consequences if it gets between moving parts;

- it's worth looking at the label of the marker. The composition should not contain a toxic substance - xylene.

When working with a marker of a certain type, you need to study the instructions. Some inks have a certain drying time, some markers are not heat resistant or will simply be invisible on a dirty surface.

The Importance of Quality Labels in Manufacturing

When buying a professional tool, expensive machines and high-quality raw materials, you need to make sure that not just anything, but a specialized device will be used for marking. This is an industrial marker. A lot depends on this small tool in production.

Marking of defects, distribution of products, a mark on its size - all inscriptions made with a quality marker will remain intact under any conditions and ensure order in the production process.

Recommended:

Cement slurry: properties, preparation rules, composition, compliance with GOST requirements, purpose and application

During the drilling process, special solutions are used to flush out cuttings and products from the development of local rock. This operation is necessary to increase the efficiency of the mechanical impact of the drilling rig and to clear the bottom hole. Washing out is carried out using cement slurries, which are prepared using special technologies

Polymer cement mortar: composition, technical characteristics, compliance with GOST requirements, purpose and application

Polymer cement mortar is one of the modifications of conventional sand-cement mortar. Polymers can also be added to mixtures that are used when laying plaster and other facing materials. The addition of this substance to the composition helps to improve its characteristics

Industrial safety of hazardous industrial facilities: rules and requirements

In modern production, unfortunately, there are accidents. However, there are special instructions, the observance of which helps to prevent disasters. Consider further the basic rules of industrial safety

Flux for welding: purpose, types of welding, flux composition, rules of use, GOST requirements, pros and cons of application

The quality of the weld is determined not only by the ability of the master to organize the arc correctly, but also by the special protection of the working area from external influences. The main enemy on the way to creating a strong and durable metal connection is the natural air environment. The weld is isolated from oxygen by a flux for welding, but this is not only its task

Ripstop fabric: what is it, composition, characteristics, purpose and application

When asked if it is a ripstop fabric, the answer is usually about a durable material. However, the name unites a whole category of very durable materials that are produced using a special technology. It comes from the English phrase (rip - tear, stop - cessation)