2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:45

When asked if it is a ripstop fabric, the answer is usually about a durable material. However, the name unites a whole category of very durable materials that are produced using a special technology. Comes from the English phrase (rip - tear, stop - stop).

Production technology

Special strength in ripstop fabrics is obtained due to the weaving of reinforced threads into the main fabric. In fabrics made of cotton, synthetics, silk and other woven materials, they are introduced by crossing, crosswise, from 5 to 8 mm from each other.

The structure of this material uses a thread with reinforced characteristics, which is usually made of polyester or nylon. The basis of the yarn in such a material can be any, both in thickness and density.

The texture of the ripstop is also very diverse. It can be pleasant to the touch, silky. Or it can be hard, rough, making sounds of crumpled paper.

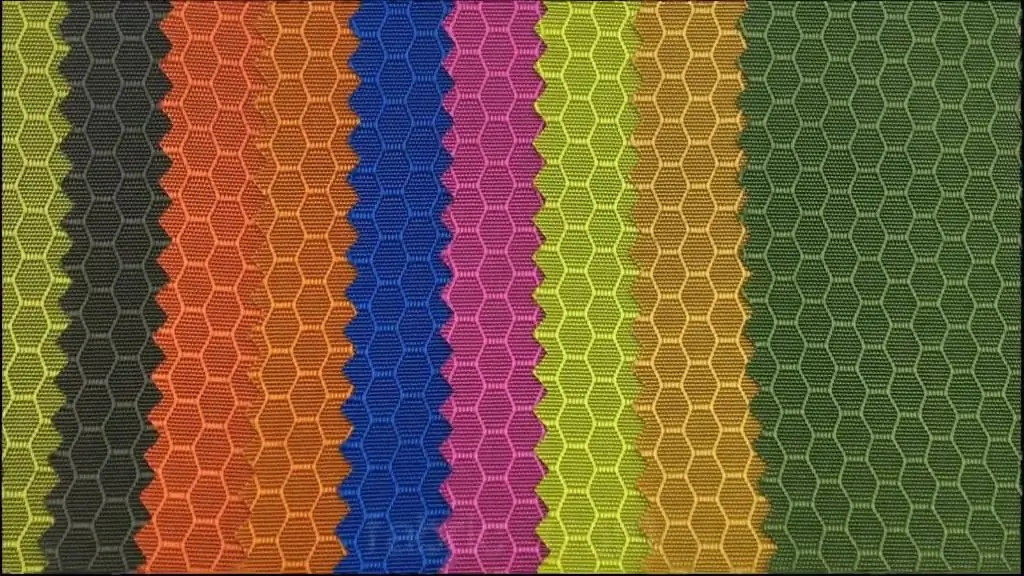

This technology is designed to create a strong grid andIt is aimed at preventing material rupture during punctures and cuts of small volume. Upon closer examination, it can be seen that the pattern of reinforcement threads is in a checkered or rhombic shape. Some manufacturers reinforce materials like honeycombs, which only benefits ripstop fabrics, increasing its resistance to excessive external influences.

Properties

Due to the fact that fibers of any raw material can be used in the basis of ripstop fabric, its properties will also be different. The main general characteristics of such materials are as follows:

- increased tear resistance;

- abrasion resistance;

- slight stretch;

- increased anti-crease;

- when using plain weave for breathability;

- Such fabrics do not shrink when wet.

Views

There are a large number of modifications to ripstop fabrics. At the same time, they can be of different density, have a variety of thickness, texture, weight, and also have different strength characteristics. It is customary to divide ripstop into the following types:

- Nylon ripstop fabric. It has high water repellency. Dries quickly after getting wet. Good resistance to decay, micro-organisms, chemicals and insects. As disadvantages, its low resistance to light exposure, as well as to high temperatures, is noted. Builds up static electricity.

- Fabricripstop polyester. Its characteristics are the same as those made of nylon, but it differs in greater rigidity and weight.

- Ripstop ballistic fabric. This material is made using polyamide yarns. They have increased characteristics in terms of rigidity and strength. The surface of such a fabric is sliding. Some time ago, body armor was made from it.

- Mixed ripstop fabric. This is a material using cotton, silk or other threads made from natural fibers. Usually reinforced threads in the composition of such a fabric with a polyester core, or finished with a cotton braid in order to prevent the negative effects of synthetics, as well as maintain hygroscopicity and breathability.

Any of the above materials can be provided with additional processing. This gives ripstop fabrics new qualities. Thus, the use of polyurethane provides high waterproof properties. Impregnating compositions are used that prevent the effects of open fire, as well as chemical active compounds. Processing leads to the fact that ripstop fabrics help to keep the person dressed in it intact. Manufacturers usually describe additional features in accompanying documents.

Due to the purpose of the ripstop fabric, it may include Kevlar thread to provide increased strength characteristics, para-aramid (fire-resistant) fiber, as well as antistatic fibers to prevent the accumulation of static electricity.

The service life of ripstop (reinforced) fabrics is long, usually at least three years. At the same time, the material retains its positive qualities, as well as its appearance.

The colors of these materials are very diverse. The most popular are camouflage colors, as well as ripstop "number" fabric.

The disadvantages include their rather high cost.

Application

Extremely durable ripstop material was developed through a program that included the creation of new models of military uniforms for NATO countries. And so far, the main volumes of these materials are supplied to the army structures and other power units.

Due to the underlying quality of these fabrics, these materials are used in areas where extreme operating conditions exist.

People who had to test clothes made from this material in extreme conditions, only positive reviews about ripstop fabric.

Production of special clothing that provides human protection must meet the requirements of hygiene, comfort and relative lightness. For such purposes, mixed ripstop fabric is used. It has a high content of natural fibers, usually up to 60%, it hangs relatively little. Such materials are used for sewing summer and winter insulated jackets, suits and bathrobes for representatives of law enforcement agencies, police officers, as well as for hunters and fishermen. The Ministry of Emergency Situations uses ripstop fabric to make protective clothing for all structural units.

For the manufacture of work clothes for fire departments, a fabric is used into which para-aramid fiber is introduced (especially durable, resistant to fire). Such material is covered with refractory layers, Teflon or silicone. Para-aramid threads are much stronger than steel and much lighter. These are elastic, stretchable and shape-recovering structures. They are non-flammable and non-melting, so the inclusion of ripstop fabrics lends them truly unique properties.

Product Repair

For minor repairs of ripstop fabric, a special reinforced tape is used, which is equipped with an adhesive base. Its purpose is the repair of products from similar materials. Cuts and punctures with a diameter of not more than 5 cm are glued with such a tape (in case of minor damage). If they are larger, then usually the tape is glued on both sides, with additional stitching with nylon thread.

Care

Ripstop fabrics are washed in automatic machines in the "synthetic wash" or "hand wash" modes. In this case, powder and liquid washable substances are used. If there is a need to clean stubborn dirt, solvents can be used, with the exception of those based on trichlorethylene.

Products made from ripstop fabric do not wring out. They are hung up and allowed to drain. They do not require ironing, making them easy to care for.

Recommended:

Industrial marker: description, composition, rules, application and purpose

Industrial marker - a writing tool for applying information on a variety of surfaces. In this case, the surface can be wood, glass, stone, metal, leather, painted materials and even rust. The requirements for such a marker are very specific

Rip-stop fabric: what is it, composition, characteristics, weaving threads and application

Rip-stop fabric - what is it? This is a high-strength material that has a combined weaving structure with reinforced yarn. It has many modifications. Rip-stop fabric is used for sewing all kinds of uniforms and things for recreation and sports, expeditions and hiking, fishing and hunting, overalls. Consider what composition it has, what properties it has

Cement slurry: properties, preparation rules, composition, compliance with GOST requirements, purpose and application

During the drilling process, special solutions are used to flush out cuttings and products from the development of local rock. This operation is necessary to increase the efficiency of the mechanical impact of the drilling rig and to clear the bottom hole. Washing out is carried out using cement slurries, which are prepared using special technologies

Polymer cement mortar: composition, technical characteristics, compliance with GOST requirements, purpose and application

Polymer cement mortar is one of the modifications of conventional sand-cement mortar. Polymers can also be added to mixtures that are used when laying plaster and other facing materials. The addition of this substance to the composition helps to improve its characteristics

Jute fabric: description with photo, structure, fabric composition and application

Jute fabric is widely used to make a variety of products. In most cases, such material is, of course, used for sewing packaging bags. But jute can also be made, for example, water filters, various kinds of decorative crafts, screens, etc