2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:28

Thermal insulation of premises intended for housing is the main task in the construction and overhaul of buildings. This problem is especially acute in areas where daily temperature fluctuations are quite noticeable.

Today, in the construction markets, you can easily find many materials whose main task is to insulate the premises. Among the wide variety of heaters, mineral wool is the most popular. Its wide distribution became possible due to the relatively low price and good performance of the declared qualities. As a heater, mineral wool is an indispensable option in its price category. It is this criterion that is decisive when choosing a material to maintain a comfortable temperature in the room.

Mineral wool, the characteristics of which are directly dependent on its constituents, has three main types. Their classification is carried out according to the types of raw materials. Slag wool was recognized as the most ineffective during various tests.

Its heat capacity and thermal conductivity are at the level of standard values. Mineral wool made fromblast-furnace slag, ideal for insulating the inner sides of walls in a room. For facades, it is better to use a different type of insulation, since the ability to absorb moisture from slag-type wool is very high. Also, do not use it to insulate pipes.

Slightly better properties and characteristics have such mineral wool as glass wool. The main raw material for its manufacture was cullet. It is during its heat treatment that glass fibers are formed, which ensure the preservation of heat.

Glass wool is a wonderful insulation, but the very process of its introduction into the walls is quite problematic. The fact is that at the slightest vibration of the fiberglass cloth, these same fibers begin to break. Getting into the air, they can create a lot of inconvenience, starting with skin itching and ending with severe irritation of the mucous membrane. Thinking about the insulation of the room with glass wool, you need to prepare in advance. First, you need to acquire such protective equipment as goggles and respirators. Secondly, it is best to use such a set of work clothes during installation, which it will not be a pity to get rid of at the end of the work. And thirdly, try to ensure that at the time of construction activities, even in neighboring rooms there are no children and asthma patients.

Well, the last type of insulation belonging to the "Mineral wool" group is stone wool.

Compared to previous competitors, it has a lot of advantages. AtIt has the highest performance in such parameters as limiting temperature, heat capacity, sintering temperature and chemical resistance in various environments. In addition, it does not cause inconvenience during installation. Also, its structure can be attributed to the positive qualities of stone wool. It is due to its porous structure that this cotton wool passes steam through itself, and does not accumulate it. This ability ensures the long-term preservation of all qualities.

Each type of mineral wool is good in its own way, but there is one quality that is inherent in all its varieties - sound insulation. Thanks to this factor, the expression "walls have ears" loses all meaning.

Recommended:

Mineral fertilizers. Plant of mineral fertilizers. Complex mineral fertilizers

Any gardener wants to get a good harvest. It can be achieved on any soil only with the help of fertilizers. But is it possible to build a business on them? And are they dangerous to the body?

Heat energy tariff: calculation and regulation. Heat energy meter

Who approves and regulates heat tariffs? The main factors affecting the cost of the service, specific figures, the trend of increasing cost. Thermal energy meters and self-calculation of the cost of the service. Prospects for billing. Varieties of tariffs for organizations and citizens. Calculation of REC tariffs, documentation required for this

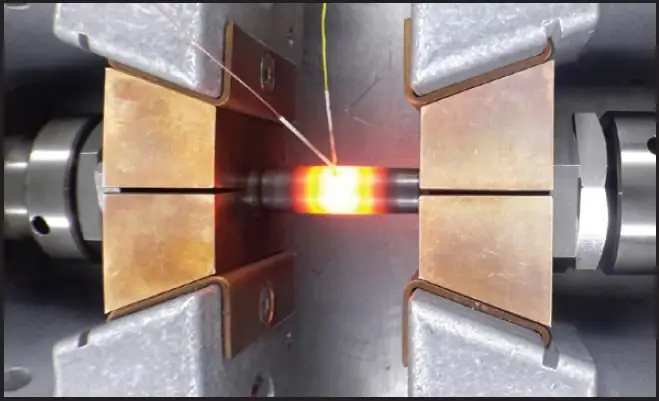

Heat resistance and heat resistance are important characteristics of steels

Ordinary structural steels, when heated, abruptly change their mechanical and physical properties, begin to actively oxidize and form scale, which is completely unacceptable and creates a threat of failure of the entire assembly, and possibly a serious accident. To work at elevated temperatures, materials engineers, with the help of metallurgists, created a number of special steels and alloys. This article gives a brief description of them

Mineral wool density: classification, advantages and disadvantages, purpose of mineral wool and application

Mineral wool is the most popular type of insulation for an apartment or house. Today it is used by everyone, from builders to the owner of the apartment, who wanted to insulate the room. The simplicity of its installation allows you to immediately insulate the entire house (ceiling, walls, floor). We will study the features and characteristics of the named material further in the article

Fuel briquettes - an alternative source of heat

Humanity, trying to solve the energy problem, is looking for and finding alternative sources of heat. One of them is woodworking and agricultural waste packed in fuel briquettes