2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:32

AISI 430 is a nickel-free stainless steel. It is widely used in the food industry. This is due to the fact that only this type of steel is allowed by government documents, and food cooked on this type of steel will not contain corrosive impurities.

General description of material

AISI 430 is used in a wide variety of machine parts that come into contact with food during cooking, storage, etc. The general description of this type of material is a general purpose ferritic chromium stainless steel. This type of raw material is characterized by the following features:

- The strength and mechanical qualities of this steel are the highest.

- Very high corrosion resistance. Weather resistance is also observed, which is due to the high quantitative content of chromium and low carbon content.

- AISI 430 is highly machinable. Great for drawing, stamping, hole punching and more.

In addition to the food industry, this material is also successfully used in other industries: architecture, design, civilmechanical engineering, automotive industry.

Where else is raw material used?

AISI 430 ferritic material has been successfully used in the industry of manufacturing machine elements and parts for devices in the wine industry. It is allowed to use this material even where there is direct contact with a substance such as must, wine, cognac spirit.

It is very important to note here that there are analogues of AISI 430. These types of steel belong to the economically alloyed nickel-free group of substances. The use of such analogues in the food industry, in other processing industries is allowed even by various state standards. Let's say the standard for making cookware and stainless steel allows you to use steel 10 x 17. However, a series such as AISI 400, which includes AISI 430, has some disadvantages.

430 material specifications

One of the minor drawbacks is that this steel cannot be used as a substitute for nickel-containing grades. This is despite the fact that nickel-free brands are far superior to their brothers in all respects.

The characteristics of AISI 430 allow it to be successfully used in the production of various equipment for the food industry and processing. This refers to installations used in oil and fat, meat, bakery, alcohol, alcoholic beverages and other categories. In addition, devices made of this steel can also be used at various stages.food preparation. Chromium steels, to which this brand belongs, and its analogues 08 x 17 and 12 x 17, have a very low coefficient of thermal expansion (CTE), especially when compared with chromium nickel-containing austenitic grades. They also have a much higher parameter such as thermal conductivity. These two characteristics of AISI 430 make it more commonly used even in tubular products, heat exchange structures, cooling towers, etc.

Steel properties

The low coefficient of thermal expansion also provides the advantage of a better fitting connection for faster heat transfer. This property is actively used in cooling systems for food containers. In addition, AISI 430 steel has shown its best performance in the gaseous environment that occurs during the combustion of a wide variety of fuels. This is true even for those environments where the presence of complete and incomplete combustion products is observed. Due to these properties, steel is actively used for the production of casings and pipelines for neutralization systems, recirculation, etc. for exhaust gases.

The use of this type of material is also due to the fact that rather complex redox processes occur in such systems, accompanied by high temperatures, catalytic reactions and an aggressive gas environment. AISI 430 stainless steel endures all these influences better than other materials.

Contentchemicals

Due to its chemical characteristics, this material is often considered a versatile material that can be used in almost any industry. The composition of this metal includes such chemicals as chromium - 16-18%, magnesium - 1%, phosphorus - 0.04%, sulfur - 0.03% and several other components Ci, C.

It is worth noting that almost everywhere this steel belongs to the group of materials that resist corrosion well. However, in practice it is still a sparingly alloyed substance. This means that the rust resistance is slightly lower, but the cost of the material is much lower. If we talk about some physical parameters of the brand, it is worth noting that all checks are carried out at a temperature of 25 degrees Celsius, and the best density of the material is 7.8 x 1000 kg/m3. In this case, the relative elongation is 20%, and the tensile strength is 480 MPa. If we evaluate the hardness of this material according to the international scale, then it will be equal to 88 HRB.

Welding and material processing

It is worth saying that this material lends itself perfectly to welding by any method and any welding machine. However, the most optimal is the use of arc welding in inert gases. In addition, the location of the welding machine is recommended to be installed from above. 309L welding wire can be used as filler material. As a treatment for welds, it is best to use chemical or mechanical methods, followed by a passivation step.

Exceptwelding, AISI 430 lends itself quite easily to other types of processing. Annealing of the substance is carried out at a temperature of 700-800 degrees Celsius, and simply cools in air. It is worth noting here that tempering for this steel is not required at all, however, if it is still necessary, then the optimum temperature is 200-300 degrees Celsius. Hot working can also be carried out. To do this, it is necessary to develop a temperature in the range from 1100 to 1150 degrees Celsius. The final temperature of this type of processing should be less than 750 degrees. It should be noted that cold working is most often chosen for AISI 430.

Recommended:

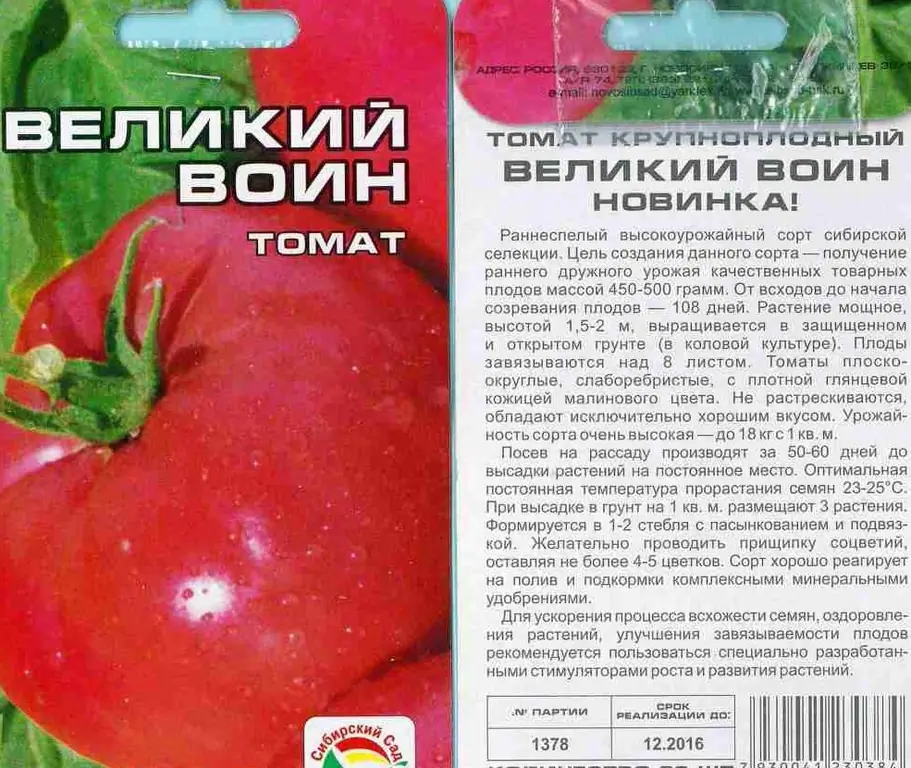

Tomato "great warrior": description, characteristics, reviews

The great warrior tomato variety was bred about ten years ago. During this period, it has become popular and in demand among lovers of large-fruited tomatoes. Its excellent taste qualities will not leave indifferent connoisseurs of this vegetable crop

The main object of commercial activity is the product. Classification and characteristics of goods

For an average person who is not related to business, the concept of an object of commercial activity is unfamiliar. However, this term indirectly applies to all spheres of our life. According to the theory, objects of this kind include everything that can be bought or sold, that is, property of any purpose, including goods. Let's find out what is meant by this concept. In addition, we will reveal the main characteristics of the product and its classification

Heat-treated wood: main characteristics, production technology, pros and cons

Almost every one of us has come across such a concept as heat-treated wood. However, few have thought about what it really means. Meanwhile, this material can be considered innovative. Due to the high temperature - from +150 °C to +250 °C - the material is strong and durable

AISI 304: properties, characteristics, composition

This article is a repository of the most important information about such a complex aspect as steel and metallurgy. But unlike the dry technical language, which in most cases is incomprehensible to the average person who does not have a higher education in the field of metallurgy, all the information included in this article is presented in much simpler words so that everyone can plunge into the topic, become interested, and in the future delve into it a little deeper

Characteristics of the Su-35. Su-35 aircraft: specifications, photo of the fighter. Comparative characteristics of the Su-35 and F-22

In 2003, the Sukhoi Design Bureau began the second in line modernization of the Su-27 fighter to create the Su-35 aircraft. The characteristics achieved in the process of modernization make it possible to call it a 4++ generation fighter, which means that its capabilities are as close as possible to the PAK FA fifth generation aircraft