2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-06-01 07:12:56

Before you get the finished part, a lot of different operations are done with the workpiece. One of the most important is the definition of the processing allowance. Its size is the difference between the size of the workpiece and the size of the part according to the drawing. In this article, we will learn what an allowance is and how to calculate it correctly.

Types of allowances

Allowance is a layer of metal that is removed from the surface of the workpiece to obtain the finished part. This is necessary in order to ensure the accuracy of the required dimensions and the required surface quality of the part. We have already found out what an allowance is, and now we will find out what varieties of it exist. Depending on the method of manufacturing the part, allowances can be intermediate, interoperational and general. As a rule, the latter are calculated by adding the interoperational. The allowance can be calculated both for a certain size and for a side.

What determines the value?

We have already found out earlier what an allowance is, and now we will find out on what factors its size may depend. First of all, of course, from technical conditionssurface quality and workpiece accuracy. In addition, the size of the allowance depends on the configuration of the part and its dimensions. Another important factor influencing the chosen value is the type of production. We must not forget about the error of installing the part in the device.

Calculation of allowance in two ways

We have already figured out what the allowance is and what factors affect its size, and now we will find out how to calculate it correctly. There are two ways: statistical (tabular) and analytical (calculated). The first is determined according to the relevant GOSTs and depends on the type of workpiece and processing route. First of all, in order to calculate the size of the machining allowance by the statistical method, it is necessary to develop a processing route for the workpiece. Further technological tolerances for technological transitions are assigned. Now, according to the tables, with the corresponding GOSTs, the allowance elements Rzand h are assigned. In addition, it is necessary to calculate the value of the total spatial errors. The technological allowance, calculated by the tabular method, must be calculated from the last transition, that is, in the reverse order of the technological process.

The following formulas are used to calculate the allowance by the analytical method.

For cylindrical surfaces:

For flat surfaces:

Where:

- Rz - microroughness value;

- h - depth of defectivelayer;

- ρi-1 - value of total spatial deviations;

- εi - blank setting error;

- i - allowance for this operation.

Intermediate machining allowances (minimum) are calculated with very high accuracy - up to a micrometer, and rounding must be done upwards.

Despite what type of allowance is calculated, it must also be taken into account that its value must exceed the minimum chip thickness that the cutting tool removes in the calculated technological operation. Of course, in different situations and with various types of workpiece processing, the above formulas may vary slightly. For example, the depth of the defective layer and its allowance (hi-1) are removed from the formula when grinding after heat treatment, since in this particular case the surface layer must be preserved.

Recommended:

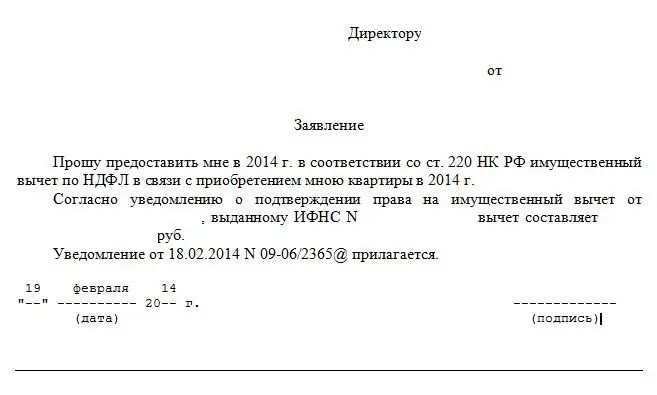

What is a property deduction, who is en titled to it and how to calculate it? Article 220 of the Tax Code of the Russian Federation. property tax deductions

Russia is a state in which citizens have a lot of rights and opportunities. For example, almost every citizen of the Russian Federation has the right to receive a property deduction. What it is? Under what conditions can it be issued? Where to go for help?

Grace period of Tinkoff credit card: recommendations and how to calculate

In the article we will consider the grace period of the Tinkoff credit card. Today, almost all banking institutions issue such an option. Tinkoff Bank has defined an individual grace period for all credit cards, as it is called in the banking environment. Why and to whom it is needed, how you can use it, we will analyze in the material below

How to calculate the profitability of an enterprise: features, formula and recommendations

Analysis of the company's activities is an important condition for effective management. Without this, it is impossible to control the work of the organization, to develop actions to improve it. One of the important indicators that are studied by analysts is profitability. It has a specific calculation formula. Correctly interpreting the result, you can determine the effectiveness of the organization's business. How to calculate profitability will be discussed in detail below

Maternity allowance: how it is calculated, calculation procedure, rules and features of registration, accrual and payment

How is Maternity Benefit (M&B) calculated? Once every woman who plans to go on maternity leave has to face this question. In 2018, a lump sum payment to expectant mothers is provided for the period of preparation for the birth of a child and after its birth

How to calculate income tax: an example. How to calculate income tax correctly?

All adult citizens pay certain taxes. Only some of them can be reduced, and calculated exactly on their own. The most common tax is income tax. It is also called income tax. What are the features of this contribution to the state treasury?