2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Leather is one of the first materials that people began to process. Initially, animal skins were dressed only in the roughest way. Gradually, such clothes became more and more attractive and comfortable. Even later woven products did not replace fur coats, shoes, belts for people. In ancient times, only small workshops were engaged in the manufacture of leather products. Today, such clothes, shoes and accessories are made industrially. Leather production today is very well developed both throughout the world and in Russia. At the same time, our country is one of the largest consumers of such material in the world.

Definition of tanneries

Compared to other materials used to make clothes, shoes and accessories, leather has simply unique properties. The skin of an animal is a very complex biological system that simply perfectly protects it from adverse environmental factors. And, of course, clothes and shoes made from such material have the same properties. They also protect their wearer well from moisture.low temperatures, etc.

Leather production is the process of dressing animal skins to a condition suitable for making clothes, shoes and accessories. Today, factories of this specialization are equipped with the most modern equipment and produce their products using innovative technologies.

Ancient use of animal skins

History of leather production has more than one millennium. The skins of the killed animals well protected the primitive man from bad weather. Such clothes made the life of cavemen more comfortable, but, unfortunately, they did not last long. Under the influence of moisture and temperature changes, the skins very quickly became unusable. Over time, people have learned to prolong the life of such material by manufacturing it. Unfortunately, it is still unknown when exactly the first leather products processed in this way appeared.

But nevertheless, scientists managed to find out that such clothes and shoes were quite popular in ancient Egypt as early as the 5th century BC. BC. In this country, once the skins were previously dried in a stretched form. Next, fat was carefully rubbed into their surface. At the next stage, the skins were kneaded until softened. From the resulting durable and fairly attractive material, they then made:

- clothes and shoes;

- belts for various purposes;

- bags, cases;

- parchment;

- boats;

- temporary shelters.

Later, methods of artistic leather processing were also invented. In the Valley of the KingsIn Egypt, for example, embroidered clothes of priests from this material, sandals decorated with gold, various expensive household items with engraving were found.

In the Renaissance, among other things, such a way of decorating the skin as exquisite embossing was invented. Then the craftsmen came up with the technique of gilding such material. Still later, French artists began decorating the skin with beautiful appliqués.

In Russia, dressed skins have also been popular since ancient times. In the old days, such workshops worked everywhere on the territory of our country. For example, archaeologists in Novgorod on the Slavic Hill opened a leather workshop of the 12th century. In the ancient structure they excavated, scientists found a vat for soaking skins, leather preparations, and shoes.

When they started processing by industrial method

In Europe, leather was made in a handicraft way until the middle of the 18th century. The first factory of this specialization was opened in France, in Alsace in 1749. Massively large and medium-sized production of leather clothing, shoes and accessories in Europe began to open only at the beginning of the 19th century.

In Russia, tanneries or, as they were then called, “yards”, existed since the 17th century. For example, a similar enterprise was opened in Moscow by order of Tsar Alexei Mikhailovich in 1668. The skins at this tannery were dressed in huge pits lined with bricks. At that time, leather dressing technologies were developed in Russia, which were subsequently preserved until the beginning of the 20th century.

In the XIX century. The "yards" of Russia produced the best leather in the world, which is very popular in Europe, America and Asia. This material was imported abroad in those days simply in huge quantities. After the revolution and the creation of the USSR, natural leather products in our country, unfortunately, became a big deficit. Only we althy people could afford such clothes and shoes.

Leather in Russia today

Immediately after perestroika, our country was literally swept by a leather boom. Products from this material, traditionally very popular in Russia, began to be delivered to the markets and newly opened boutiques by numerous "shuttles". Similar products have not become less in demand in our country in subsequent years. Today, Russia is perhaps the main producer and consumer of leather goods in the world.

Manufacturing today: varieties of material

Each skin is a truly unique material. Its properties depend on the type of animal from which it was obtained, its age, the characteristics of keeping and feeding, the dressing methods used. In Russia, at the moment, all technologies of leather production are regulated by GOST 3123-78. Therefore, products of this type are produced in our country of sufficient quality. There are many types of leather in Russia and the world at the moment:

- saddle-saddle - a rough skin of cattle, pigs and horses used to make belts;

- yuft - combined tanning material,made from thinner skins of pigs, cattle or horses;

- calf - soft durable leather with a glossy front surface, obtained from the skins of calves up to 6 months;

- outgrowth - also quite soft leather made from calf skins up to 1 g;

- semi-skin - an even thicker and slightly rough material made from the skins of cattle under the age of one and a half years;

- calf and bull - skin made from the skins of young heifer cows and bulls older than one and a half years;

- chevro and goat - a material with a peculiar beautiful fine-grained pattern obtained by tanning goat skins;

- chevret - tanned sheep skin (less durable than goat skin);

- pigskin - a material with a rough coarse-grained surface, having through holes from the bristles;

- suede - skins of deer, elk, sheep, wild goats, processed by fat tanning;

- velor - a material made from calf, chevro, goatskin, chevret or pigskin.

Also distinguish between such types of leather products as light nubuck, laika, lacquer material.

Main processing technologies

Types of leather by modern industry are produced, therefore, just a huge amount. The varieties discussed above are produced by tanning or fatliquoring. It is these skins that are currently the most common on the market. But sometimes animal skins can be processed using other technologies. In addition to tanned, leathers are currently distinguished:

- raw;

- rawhide.

In the leather industry in Russia, as well as all over the world, all three methods of dressing skins can be used.

Tanning and fatting

The skin of any animal consists of three layers, which are either transformed or removed during the dressing process. Outside, such material covers the epithelium. The middle layer of the skin is considered the main one. It is formed by collagen protein molecules. The lower fat layer of the skin has a loose structure. It is he who is removed in the process of dressing to a certain thickness.

The middle collagen layer of fresh skin remains mobile. That is why this material is flexible and elastic. After a certain period of time, the fibers of the middle layer begin to dry out and stick together into a continuous mass. As a result, the skin becomes hard and brittle. To prevent this from happening, during the production process, special substances are introduced into the middle layer of this material - tanning agents or fats, which do not allow the fibers to lose elasticity and stick together.

What is rawhide

Currently, in the leather industry, animal skins are processed primarily by tanning. But sometimes the ancient method of making rawhide can be used today. Such material is considered to be of higher quality than tanned, and it is usually made using the following technology:

- the skin is washed and skinned (the fat layer is removed);

- remove hair from the skin by scraping;

- carefully knead the skin with their hands, stretching italong a board or steel corner, as well as twisting in different directions, until softened.

Leather made in this way becomes slightly slippery when wet. To prevent this from happening, at the final stage it is fattened or impregnated with special substances.

Raw skin

This technology is rarely used in leather production today. Such material is otherwise called naked. Raw leather is made by a fairly simple method. In this case, only the hair and the lower fat layer are removed from the skin of the animal. After drying, such skin becomes horny. This material is used in our time for the manufacture of whips for racehorses, membranes of some musical instruments, parts of looms.

The main centers of leather production in Russia and the world

In our country, enterprises of this specialization operate in many regions. For example, leather and leather products are produced by factories such as:

- Volgograd tannery.

- Yaroslavsky.

- Taganrog.

- Bogorodsky.

- Tverskoy.

- Rybinsky, etc.

Of course, this branch of light industry is well developed in our time and in many other countries of the world. The main centers for the production of leather raw materials on the planet, in addition to Russia, today are:

- Bangladesh (Hazaribagh town).

- China.

- India.

- Southern Europe.

Total number of employees,There are currently 500,000 people employed purely in the manufacture of leather, which are then used for the production of clothing, footwear and accessories in the world.

Recommended:

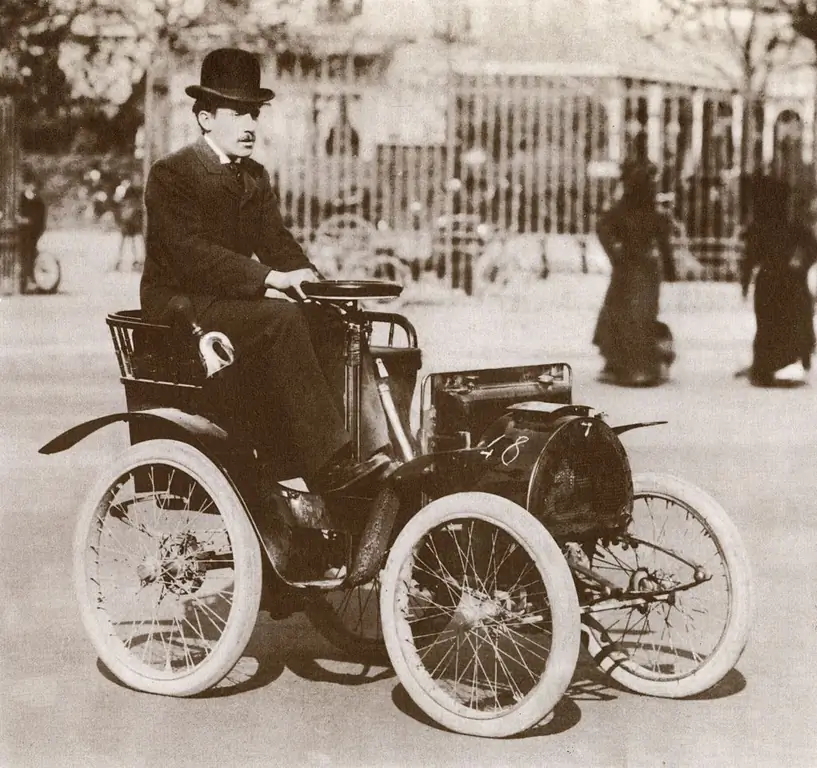

"Renault": manufacturer, history and date of creation, management, country, technical focus, development stages, introduction of modern technologies and car quality

The Renault manufacturer produces high-quality cars that are in demand in many countries of the world. The products were to the taste of Russian motorists. In 2015, the French concern produced the millionth car from the lines of the Russian plant

Leather industry: history and development, results and prospects of the industry

Humanity has been processing leather since time immemorial. The leather industry has undergone significant changes over the millennia. The development of the country's economy depends partly on light industry. Leather production is the largest consumer of chemical materials and equipment

History of porcelain: a brief history of development, types and description, technology

Ceramic products are the oldest kind of craft from all the skills mastered by man. Even primitive people made primitive utensils for personal use, hunting decoys and even earthenware utensils like hut ovens for cooking. The article tells about the history of porcelain, its types and method of obtaining, as well as the distribution of this material and its path in the artistic work of various peoples

Vitamin plant in Ufa: history and date of establishment, management, addresses, technical focus, stages of development, introduction of modern technologies and product quality

The life of a modern person takes place in a rather unfavorable ecological environment, accompanied by intellectual and emotional overload. You can't do without taking vitamins and minerals even in the summer. This material will focus on one of the oldest enterprises in Ufa, which is engaged in the production of useful products

Irkutsk heavy engineering plant: history and date of establishment, address, management, technical focus, stages of development, introduction of modern technologies and quality

Irkutsk heavy engineering plant is a city-forming enterprise producing equipment for leading industries in Russia. The company's products are supplied to the domestic market, finds recognition and demand abroad