2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:38

Specialization is the differentiation of the production process for the manufacture (repair) of products. At the same time, a specific structural unit or a specific operation is assigned to a subdivision of an enterprise (workshop, section, position). The calculation of the coefficient of specialization of production is a necessary condition for analyzing the type of production system and the level of technological development of the enterprise as a whole.

Specialization conditions for systems

There is a direct relationship between the coefficient of specialization and the characteristics of production systems. So, for mass types, specialization in a specific operation, which is repeated in time, is characteristic. To do this, the following condition must be met:

∑Ni × ti=Fd,

- where Ni - the volume (program) of manufacturing the i-th part for the specified time, units;

- ti - operation duration, hour;

- Fd - valid annual use fundequipment, hour.

In serial systems, specialization takes place in a limited number of operations, which at the same time alternate in the prescribed order. The condition will take the form:

∑Ni × ti ≦ Fd

Calculation of the coefficient of specialization

The study of aspects of the development of specialization of an enterprise or individual units is carried out using a number of characteristics:

- specific volume of special (automatic) equipment of the enterprise;

- amount of equipment used in mass production;

- parts of special technological elements in the overall process;

- percentage of unification regarding units and parts;

- percentage of typical (homogeneous) technological processes.

Specialization coefficient can be determined in this way:

Кс =∑Кi ÷ ni,

- where Ki - the number of operations in the i-th position (workplace);

- i - number of positions.

Influence of processing technology

In practice, the type of specialization of the enterprise or its part affects the determination of the coefficient of specialization. Most of the technological processes used, as a rule, are single or group.

Single items are based on parts of the same name, dimensions and manufacturing methods. This homogeneity allowsthe use of special tooling and equipment, allows you to achieve maximum detail of the elements of the process. These molds are well adapted to mass production systems.

Group processes are based on the similarity of operations in terms of content and form, but are typical for products with different design features. This form of technology construction makes it possible to change tooling in the process of processing products, through the use of complex parts. Each of these parts is associated with a specific technology - grinding, turning, milling, etc. Group technology is suitable for mass production, allowing you to increase the technical and organizational level and creating more advanced production conditions (like higher-level systems).

Calculation of coefficient taking into account technology

The coefficient of specialization is determined according to the existing production structure of the considered department (section) of the system:

- for each division - in case of using shops with a subject orientation (operations on similar batches of parts of different content) - trolley shop, wheel shop;

- calculation is carried out for the general scheme of the enterprise - if the workshops are organized on a technological basis (the same operations on nodes of different design base) - galvanic, welding, assembly.

When an enterprise uses both of these technologies, the specialization coefficient formula should take into account the loading of equipment (equipment) and the adopted processing scheme.

BIn this case, the coefficient is defined as follows:

Kco =Kze × (Kzed / K oz) + Kzg × (Kzgr / Koz),

- where Kco is the coefficient of specialization of the whole system;

- Кze and Кзг - operation coefficients for single and group technology;

- Kzed and Kzgr - load factors of working positions, respectively, according to different processing schemes (single and group);

- Кoz - average load factor of jobs (positions).

Conclusion

As can be seen from the analysis, specialization has different forms and aspects of use. It manifests itself at all levels of production and has a direct impact on the further development of the enterprise over time. Deepening the specialization of all levels of the production system makes it possible to move to the most productive and high-quality enterprise management models.

Recommended:

Calculation of average earnings upon dismissal: calculation procedure, rules and features of registration, accrual and payment

To get confidence in the correctness of all accounting calculations upon dismissal, you can easily do all the calculations yourself. The calculation of the average earnings upon dismissal is carried out according to a special formula, which, with all the features, is given and described in the article. Also in the material you can find examples of calculations for clarity

Hydraulic system: calculation, scheme, device. Types of hydraulic systems. Repair. Hydraulic and pneumatic systems

The hydraulic system is a special device that works on the principle of a liquid lever. Such units are used in the braking systems of cars, in loading and unloading, agricultural machinery and even in the aircraft industry

Production and production systems: concept, patterns and their types

Production systems are structures that involve people and equipment working together. They perform their functions in a certain space, conditions, working environment in accordance with the tasks

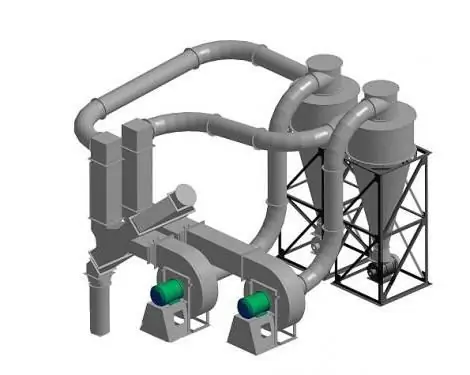

Aspiration systems: calculation, installation. Production of aspiration systems

Aspiration systems are systems that are designed to purify the air. The use of these installations is mandatory at all industrial enterprises that are characterized by harmful emissions into the atmosphere

OSAGO calculation formula: calculation method, coefficient, conditions, tips and recommendations

With the help of the OSAGO calculation formula, you can independently calculate the cost of an insurance contract. The state establishes uniform basic tariffs and coefficients that are applied in insurance. Also, regardless of which insurance company the owner of the vehicle chooses, the cost of the document should not change, since the rates should be the same everywhere