2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:32

Currently, aspiration systems are quite common, as the development of the industry only intensifies every day.

General information

Filter systems with bag filters are the common systems that are most common. They are designed to filter air that contains solid particles, the size of which reaches 5 microns. The degree of purification of such aspiration systems is 99.9%. It is also worth noting that the design of this filter unit, which has a storage hopper, allows it to be used for installation in traditional air purification systems that have an extensive air duct system, as well as a high-power exhaust fan.

The central accumulator in such systems is used to store, as well as dose and dispense shredded woodworking waste. The production of this bunker is carried out with a volume of 30 to 150 m3. In addition, this aspiration system hopper is equipped with parts such as sluice loaders or augers, explosion and fire protection system, system,controlling the filling level of the bunker.

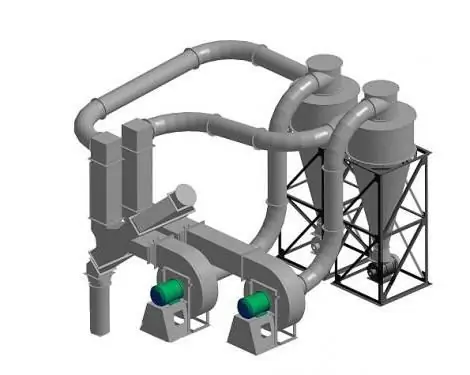

Modular systems

There is also a modular air aspiration system, which is designed for the following purposes:

- Ensure complete and reliable dedusting of the air in the production room at the level prescribed by regulations.

- The most important task is to protect the atmospheric air from pollution by the enterprise.

- Also, this system is designed to remove woodworking production waste from technological equipment in the form of a mixture of air and dust, as well as the subsequent supply of this mixture to dust collectors.

- The modular system is also intended to organize the waste of emissions from the place of air purification to the place of its disposal. It can function fully automatically.

- The last function that this system performs is the dosed supply of sawdust to the fuel hopper. This operation can also function in fully automatic mode, but manual is also present.

Equipment for calculation

In order to calculate the aspiration system, you must first combine it into a common network. These networks include:

- Equipment that functions simultaneously.

- Equipment that is close together.

- Equipment with the same dust or similar in quality and properties.

- The last thing to consider isequipment with close or the same air temperature.

It is also worth noting that the optimal number of suction points for one aspiration system is six. However, more are possible. It is important to know that in the presence of equipment that operates with a constantly changing air flow, it is necessary to design a separate aspiration system for this device or add a small number of “accompanying” suction points (one or two with low flow) to the already existing one.

Air calculation

In order to install an aspiration system, it is important to make accurate calculations. The first thing that is determined in such calculations is the air flow for aspiration, as well as pressure losses. Such calculations are carried out for each machine, container or point. The data can most often be taken from the passport documentation for the object. However, it is allowed to use AI from similar calculations with the same equipment, if any. Also, the air flow rate can be determined by the diameter of the pipe that sucks it out or by the hole in the body of the suction machine.

It is important to add that it is possible to eject air entering the product. This happens if, for example, air moves through a gravity pipe at high speed. In this case, additional costs arise, which must also be taken into account. In addition, in some aspiration systems it also happens that a certain amount of air leaves with the exhaust products after cleaning. This number is alsomust be added to the expenditure.

Expense calculation

After carrying out all the work to determine the air flow and possible ejection, it is necessary to add up all the numbers obtained, and then divide the amount by the volume of the room. It should be borne in mind that the normal air exchange for each enterprise is different, but most often this figure is in the range from 1 to 3 aspiration cycles per hour. A larger number is most often used for calculating the installation of systems in rooms with general supply and exhaust ventilation. This type of air exchange is used in factories to remove harmful fumes from the premises, to remove impurities or unpleasant odors.

When installing an aspiration system, an increased vacuum may be created due to the constant suction of air from the room. For this reason, it is necessary to provide for the installation of an inflow of outside air into it.

Fire suction

At present, the aspiration fire system is considered the best means of protecting the premises. An effective way of warning in this case is considered to be aspiration with ultra-sensitive laser smoke detectors. The ideal place to use such systems is archives, museums, server rooms, switch rooms, control centers, hospital rooms with high-tech equipment, "clean" industrial areas, etc.

In other words, this type of aspiration fire alarm system is used inpremises that are of particular value, in which material values \u200b\u200bare stored or in which a large amount of expensive equipment is installed.

Closed suction system

Its purpose is as follows: sanitation of the tracheobronchial tree under conditions of artificial lung ventilation and while maintaining asepsis. In other words, they are used by doctors for complex operations. This system includes the following:

- The design of the device is made entirely of polyethylene, polyvinyl chloride, polypropylene. Its latex content is zero.

- The device contains a swivel angled connector, the size of which is completely standardized, and also has a movable inner ring. The presence of this part ensures a reliable connection with the connector.

- The system is supplied with a protective sheath for the suction catheter, which is designed to keep this part sealed.

- Catheter sizes are color-coded.

Types of systems

Currently, there is a fairly broad classification of types of filter systems. Some companies, such as Folter, manufacture almost every kind of suction system.

The first separation of systems is carried out according to the nature of air circulation. On this basis, all of them can be divided into two types:recirculating and direct-flow. The first class of systems has such a significant difference as the return of the selected air from the room back, after going through a complete cleaning process. That is, this installation does not produce any emissions into the atmosphere. Another advantage follows from this advantage - high savings on heating, since the heated air does not leave the room.

If we talk about the second type of systems, then their principle of operation is completely different. This filter unit completely takes air from the room, after which it carries out its complete cleaning, in particular from substances such as dust and gas, after which all the air taken in is released into the atmosphere.

Installation of suction systems

In order to start the installation phase of the filtration system, design work is first carried out. This process is very important, and therefore it is given special attention. It is important to say right away that an incorrectly carried out design and calculation stage will not be able to provide the necessary air purification and circulation, which will lead to bad consequences. For successful drafting and subsequent installation of the system, several points must be taken into account:

- It is important to determine the amount of air consumed per aspiration cycle, as well as the pressure loss at each point of its intake.

- It is important to correctly identify the type of dust collector. To do this, you need to choose it correctly according to its own parameters.

Carrying out calculations and drawing up a project is not a complete list of what needs to be done before starting the installation processsystems. In other words, installing filters is the easiest and last thing the pros do.

Recommended:

Hydraulic system: calculation, scheme, device. Types of hydraulic systems. Repair. Hydraulic and pneumatic systems

The hydraulic system is a special device that works on the principle of a liquid lever. Such units are used in the braking systems of cars, in loading and unloading, agricultural machinery and even in the aircraft industry

Production and production systems: concept, patterns and their types

Production systems are structures that involve people and equipment working together. They perform their functions in a certain space, conditions, working environment in accordance with the tasks

Modern production. The structure of modern production. Problems of modern production

Developed industry and a high level of the country's economy are key factors influencing the we alth and well-being of its population. Such a state has great economic opportunities and potential. A significant component of the economy of many countries is the production

Business idea: production of bricks. Technology and installation for the production of bricks

You can create your own business that will meet your requirements and also become a source of income. However, in order to obtain high-quality bricks, it is necessary to comply with the technical conditions and adhere to the manufacturing process. The production of bricks at home does not involve the use of expensive equipment. The most important condition is the correct preparation of raw materials

Coefficient of specialization of production systems: calculation features

The development of production over time is characterized by a certain level of specialization. An increase in production volumes, the introduction of new technologies and methods makes it possible to switch to a more advanced form of technological organization. To determine its type allows the calculation of the coefficient of specialization