2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:27

Production systems are structures that involve people and equipment working together. They perform their functions in a certain space, conditions, working environment in accordance with the tasks. Production and production systems are made up of certain elements.

General characteristics

Production systems are capable of independently or in cooperation with each other to satisfy certain requests and needs of potential consumers through the services and goods produced. The emergence of such structures is determined by the emergence or formation of demand in the market. They must be adapted to meet the customer's need for a long time. Thus, the goals of the production system are to manufacture and sell products that are needed in the market.

Stages

The production process system is a sequence of operations associated with the transformation of materials and raw materials into services and goods. Within this complex there is a changetools used at work. They go through the following stages:

- Mechanization. As part of it, manual labor is partially replaced by machine labor.

- Automation. It represents the complete transfer of mechanical operations to the equipment. Automation minimizes human intervention.

- Standardization. It involves the uniformity of parts, operations, goods, as a result of which the components of products and people become interchangeable.

- Computerization. It allows you to create opportunities for flexible changeover of equipment for the manufacture of a diverse range of products.

Types of production systems

They are determined in accordance with the stages of the formation of modern industry. Depending on the methods of cost reduction, organization, technological level, the following types are distinguished:

- Mild pre-scientific (military-anarchist).

- Soft science based on flexible technologies (Toyotism).

- Hard science (Fordism).

Let's take a closer look at these types of production systems.

Military anarchist structure

Such a system of production activities has the following features:

- The key direction is the capture of new markets for the sale of goods due to their reduction in price.

- Manufactory and factory production of products. It is based on mechanization, the transfer of key functions to equipment, and provides for narrow, simple speci alties of workers.

- Template and semi-template monotonous activity.

- Forced work rhythm set by the machine.

- Extensive use of material and human resources to reduce their cost.

- Easy operations.

Management of the production system in this case is of a conflict nature. Actually, because of this, it is called military-anarchist. Relationships are rather unstable within production.

Fordism

G. Ford became the founder of this production system. He developed a theory, the key provisions of which are:

- High pay for worker.

- Control over the number of hours. The employee must work 48 hours a week, but no more.

- Maintaining the best condition of machines, their absolute cleanliness.

- Cultivating people's respect for themselves and for each other.

In accordance with these principles, an 8-hour day was introduced and a salary was set twice as high as was provided for in generally accepted norms. Ford, in addition, created schools with scholarships, opened a sociological laboratory, which carried out a study of working conditions, leisure and life of employees. At the same time, he cared about potential consumers. In particular, special attention in production was paid to the quality of products, the development of a service network, cars were constantly improved, selling prices were reduced. The introduction of machines for the implementation of hard work was a strict requirement,rapid implementation of innovations. Hygiene and cleanliness were also strictly controlled, the psycho-physiological characteristics of employees were taken into account when they were assigned to perform certain operations (requiring a creative look or monotonous). Ford was one of those who created the philosophy of practice. The merit of this man and others who have propagated similar ideas is to establish the key principles on which the organization of production systems is based. At present, they have not lost their relevance, but rather, on the contrary, they have become more than in demand.

Key Features

The main task of Fordism is to reduce production costs. Among the key features of the structure, the following should be mentioned:

- Production assembly line.

- Availability of a fleet of specialized machines.

- Template simple work.

- Forced rhythm defined by pipeline.

- Low qualified staff.

- Serial (mass) production.

- Small cost to attract resources to create a new conveyor.

- High turnover.

Management

It included:

- Production planning. It was carried out in the form of rationing of financial, labor and material resources.

- Routing. It represents the development of sequences and paths for the passage of goods through the equipment.

- Dispatching. It provided the distribution of routetechnological maps and production tasks for the divisions of the enterprise.

- Calendar planning. It represents the formation of a schedule and the coordination of various stages and methods of processing products (sequentially or in parallel).

- Quality control.

- Improving production methods and distribution of functions among employees.

Toyotism

The production systems discussed above are not flexible or able to adapt to changing conditions. Toyotism is a response to the need for highly qualified specialists, the growth of industrial mobility. It acts as a modern production and economic system. Its key principle is to find the optimal combination of human values, learning, continuous adaptation to constantly changing conditions. It involves the involvement of highly qualified personnel, the use of semi-template and creative work. This structure employs flexible design and manufacturing systems. The whole company acts as a complex of highly specialized enterprises, a network of branches is developed.

Development of flexible production systems in Japan

They began to take root relatively recently, in the middle of the 20th century. The successful development of production systems of this type is noted in Japan. A computerized model began to operate at enterprises. It coordinates the information of all structural divisions and ensures uninterrupted work. Production-a technical system of this type involves direct administration of the very course of production and control of inventories. The continuity of work is ensured by the delivery of materials "just in time" to the right place and in the required quantity. This model is called "kanban". The planning department of the enterprise weekly or monthly develops a schedule for the release of new products. However, it does not act as a production scheme for each workshop. The operational schedule, developed every day, coordinates the work of the main conveyor exclusively. Other shops communicate through the kanban system. Japanese technology is known throughout the world for its quality. Such popularity is ensured by strict control at the enterprise. Every employee in every company feels an individual responsibility for the manufactured products. For quality control, special circles are formed at the enterprise. Their members must continuously improve their skills and knowledge.

Principles

The main production systems in the modern world are based on:

- Resource planning. In accordance with the general working projects, a forecast of the conjuncture, financial indicators, engineering developments, employment, schedule is formed.

- Quality control.

- Management of labor resources. It includes the study of individual characteristics of a person to ensure the continuity and safety of work. Enterprises adopt flexible schedulesthe range of functions of employees is expanding. The workers themselves take part in the organization of production. Particular attention is paid to group and internal self-control of specialists.

Features of Russian industry

Currently, enterprises have a model that covers all stages of the enterprise. These include not only the direct production of products, but also the supply of raw materials for its manufacture, as well as the sale of finished products. The quality of the goods, the amount of costs, and the competitiveness of the enterprise depend on how efficiently the system is organized. The key factors hindering the development of production systems in the Russian Federation are the lack of qualified managers and the lack of information about the potential and prospects for modernization.

Specific administration

Management of the production system is the conscious regulation of the entire operation of the enterprise. First of all, a project of the optimal model of the functioning of the company should be developed. Management involves making decisions about the location of facilities, the introduction of norms and standards. The functioning of the system must be constantly monitored. This means that the routes for the passage of orders must be established, the deadlines for their delivery must be determined. Equally important is the accounting of materials, assemblies, parts and products within the enterprise. Such control should be ensured at all stages of the company's work. To achieve competitiveness, an enterprise must produce a demanded product onmarket. At the same time, it should have its own characteristics that distinguish it for the better from the products of other companies. In this regard, a team of specialists must develop a project for products that the enterprise will produce, or take advantage of existing promising developments.

Recommended:

Indicator of Price Action patterns. Indicators for identifying candlestick patterns

Experts of the financial market have specially developed automated assistants for stock speculators who can independently determine the pattern and give a signal. It is these indicators of patterns that will be discussed in this article. The reader will learn what tools exist for determining candlestick patterns, how to install them on the chart and how to use them correctly

Hydraulic system: calculation, scheme, device. Types of hydraulic systems. Repair. Hydraulic and pneumatic systems

The hydraulic system is a special device that works on the principle of a liquid lever. Such units are used in the braking systems of cars, in loading and unloading, agricultural machinery and even in the aircraft industry

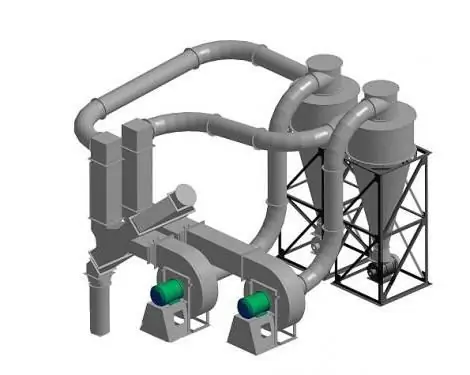

Aspiration systems: calculation, installation. Production of aspiration systems

Aspiration systems are systems that are designed to purify the air. The use of these installations is mandatory at all industrial enterprises that are characterized by harmful emissions into the atmosphere

Insurance: essence, functions, forms, concept of insurance and types of insurance. The concept and types of social insurance

Today, insurance plays an important role in all spheres of life of citizens. The concept, essence, types of such relations are diverse, since the conditions and content of the contract directly depend on its object and parties

Visa and Mastercard systems in Russia. Description of Visa and Mastercard payment systems

Payment system - a commonality of methods and tools used for money transfers, settlements and regulation of debt obligations between participants in economic turnover. In many countries, they differ significantly from each other due to the diverse provisions in the levels of economic development and the characteristics of banking legislation