2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:38

In the history of the development of industrial production systems, events took place that created the prerequisites for a revolutionary leap in technology. And by the fact of their existence, they led to a change in the appearance of not only enterprises where innovative processes were carried out, but also of the whole world. The creation of the first steam engine was the initial impetus for the emergence of technological machines and mechanisms, which a hundred years later turned into modern equipment for the manufacture of products. The discovery of electromagnetic induction became the basis of a new elemental base, from the construction of the first rechargeable batteries to modern computers, telephones and the electrical part of various devices. Henry Ford's introduction of the first assembly lines for automobiles marked the development of large enterprises for many decades to come. Toyota's "Lean Manufacturing" methods and concepts have made it possible to create flexible, tailor-made systems with minimal resource consumption and maximum product quality. In fact, we are talking about industrial revolutions in the field of production and provision of services.

Intensive development of informationtechnologies in the fields of communication and communication, designing complex systems and developing new information management technologies created the prerequisites for the emergence of the following innovations - these are CALS technologies.

Relevance of application

Today, there are practically no types of human activity without the use of the results of information development. Medicine, light and heavy industry, gaming industry, scientific and innovative activities - various software products facilitate processes, and often are their critical element.

Further deepening of the informatization of the spheres of activity of industrial enterprises today is an important condition for the successful development of the economy. Intelligent engineering processes, automated processes for managing the production activities of an enterprise, together with its technical re-equipment and the creation of innovative computerized technological processes, allow to a large extent to form optimal resource-intensive production with full disclosure of industrial potential.

Progressive methods and approaches to production management that have emerged in recent decades are usually referred to as logistics technologies. This is due to the fact that logistics explores and forms various flows in production and organizational activities, which include material, financial and information structures. Therefore, it is more correct to talk about CALS-technologies in logistics.

The main difference of this approach is to create a management system that automates not certain types of work, functions and tasks, but allows you to formalize all the processes of the enterprise - design, production, supply, sales, after-sales service.

History of Creation

In general terms, CALS-technology is the process of creating a single information space in a single product life cycle support system. With the development of production systems, it became necessary to develop mechanisms and procedures for the rapid exchange of data between various subjects of production relations at different stages of the use of products.

Initially, this concept was implemented in the US military to reduce the amount of paperwork, increase the efficiency of feedback between customers and suppliers of weapons and ammunition, improve system manageability and reduce overall costs for the information area. The abbreviation CALS itself stood for "Computer Supply Support".

Having a reasonable efficiency (according to experimental data, labor productivity has significantly increased and operating losses have decreased), over time, CALS-technologies and CALS-systems have significantly expanded their field of activity. Various branches of mechanical engineering, construction and transport sectors, the area of project development of high-tech industries. Moreover, if initially the application was limited to production and operation, now the concept was in effectat all stages of the product life cycle - from market analysis to the disposal process due to physical or obsolescence.

Today, the use of CALS technologies has become a cross-national strategy for paperless electronic process management at various levels of the product life cycle. There are several dozen organizations coordinating aspects of the development of these systems at the level of various states and alliances (for example, the North Atlantic Alliance).

A brief summary

The main principles of CALS-technologies are based on the control and organization of the stages of product existence. These include:

- ensure system management (use of special information spaces);

- cost minimization at all stages;

- use of standard mechanisms for describing managed objects (integration of information flows);

- differentiation of software elements based on the use of common standards (data and access interfaces) and the use of platforms on a commercial basis;

- representation of information on a paperless basis with the priority of using an electronic signature;

- associated engineering of all processes;

- continuous adjustment and improvement in order to create an optimal management model.

Creating an information plane involves solving a problem on two levels:

- automation of individual elements of production and the formation of related information management flowsdata;

- composition of various information blocks (which, in addition to obtaining a homogeneous information environment, also guarantees the composition of the overall strategy of the enterprise).

Timely and continuous development of CALS technologies is a necessary condition for the technical development of the production system.

The benefits of an integrated environment include:

- protect data over time (ensure integrity);

- providing access to information for all project participants, regardless of their position in space;

- minimizing data loss;

- flexibility of the system to respond to the adjustments made (changes are available almost instantly throughout the system);

- increasing processing throughput;

- Powerful and diverse design and support platforms.

Advantages of CALS technology in mechanical engineering

Prospects for the use of CALS in industrial enterprises lie in the formation of a specialized organizational and information environment that allows:

- significantly increase the level of cooperation between different industries due to uniform standards of information processing;

- reduce the influence of the territorial location of enterprises and thereby limit the influence of distances on the effectiveness of interaction;

- create virtual production elements that allow you to control the processes of design, production and operation of products at the level of individual practical tasks;

- protect work results based oncontinuity of work results at all stages of the product life cycle;

- optimize costs by reducing paperwork;

- use the "transparency" of management and control processes, thanks to the development of integrated models;

- create powerful information support for all stages of the production cycle;

- create a common product information standardization system;

- ensure the required level of product quality.

Application of the fundamentals of CALS-technologies is extremely important for keeping the level of development of the enterprise with modern trends in the international industrial arena.

General approaches to creating information infrastructure

The main mechanism for the design and subsequent adaptation of products to serial production is the technical preparation of production. As a rule, it is implemented in three main stages - design development and graphic documentation, technology development and production system preparation, as well as the choice of optimal design and technology options from the point of view of economic efficiency. This procedure, from the moment it was used at the defense enterprises of the USSR in the mid-60s, has become familiar to civilian sector systems. Thanks to its use, the time for designing and preparing for operation of new structures has been significantly reduced, and the level of product reliability has more than doubled. At the same time, significantquality assurance results.

Modern computer technology has tools and approaches that allow you to consolidate all production data and present them in the form of an electronic model. This facilitates engineering analysis, the creation of various design (technological) specifications, the development of technical manuals and catalogs of ready-made technical solutions. CALS, FDI informatization technologies are a general trend in the development of production design systems.

Research areas

Examples of CALS-technologies are digital production design methods that support product lifecycle management (Product LifecycleManagement) - the so-called PLM-systems.

These include the following classes of systems:

- CAD - (Computer Aided Design) - solving problems of designing products and elements; modeling of objects on a plane (2D model) and in space (3D model); means of obtaining drawings; data archives on structural elements and creation of document templates.

- CAE - (Computer Aided Engineering) - study of the properties of objects (during manufacture and operation); creation of verification systems for the analysis of the object according to the developed model; optimization of object parameters according to specified conditions and restrictions.

- CAM - (Computer Aided Manufacturing) - programming of CNC machine controllers; study of tool trajectory options according to the algorithms of the machined surface; analysis of geometric conflicts; fitting to equipment.

- PDM -(Product Data Management) - data storage and documentation control; creating an archive of samples; ensuring access to information and its protection.

Enterprise resource management

Another important function of computational methods is the real-time management of various resources and enterprise flows - logistics, financial, warehousing, personnel, planning and marketing. Systems that implement the above tasks are referred to as ERP systems (Enterprise Resource Planning - enterprise resource management).

Such systems represent a new methodology for managing CALS technologies, which implements the required functionality based on a special information infrastructure.

Typical functions of this class of software products include:

- creation and control of various specifications (allows you to determine the final product, take into account all the necessary resources for production);

- sales management (product sales forecast based on sales plans);

- analysis of the need for materials (determining the size of lots and delivery times, specific groups of raw materials and components);

- organization of procurement activities (formation of supply contracts, optimization of warehouse activities of the enterprise);

- planning the utilization of production capacities (at the level of both the entire enterprise and individual workshops or jobs);

- control of financial resources (accountingand financial audit).

Note that the presented CALS-technologies are the conceptual basis of information support for the life cycle of the creation and operation of products. Which shows its maximum efficiency when both systems (PLM and ERP) merge.

System usage

CALS-technologies are, first of all, a method of information support for business processes, which has found its application in various areas of production activity. The effectiveness of its dissemination and use is based on the systematic development of an appropriate information environment. To achieve this goal, a necessary condition is the use of special compositional approaches to the formation of new support systems.

An example of a similar company in the Russian market is the Research Center for CALS-technologies "Applied Logistics". The main tasks of the company lie in the plane of progressive platforms and standards for their use. The main activities are: the implementation of operational monitoring of various design data and minimization of product losses.

Research Center for CALS-technologies - developer of several well-known authoring platforms. Let's make a brief review of them.

PDM application class

Represents a data source based on models that are formalized by special international ISO standards.

The most common features include:

- control of information about the main properties of structures;

- research device forsubsequent system changes;

- analysis of compliance with logistics principles;

- collecting data on the parameters of the quality component of products;

- control array operations;

- ensuring the interaction of element sets (CAD-CAM, etc.).

As you can see, the use of CALS technologies provides full control of the product at the level of the element base of the design.

Additional features:

- operation and control of lists of classifiers (reference data banks);

- manufacturing information management;

- manage product parameters in real time;

- development of tree diagrams of the variable structure of products;

- working with patterns of structures according to previous options;

- analysis of the characteristics of elements according to various indicators;

- product layout with documentation: models, drawings, textual information, data tables;

- working with archives;

- formation of specifications and statements;

- data management of technological processes, equipment, tooling;

- detailing of manufacturing technology (routes, operations, transitions);

- analysis of the interaction of technology stages with the element base of the design;

- determination of consumption rates of various resources in the system;

- visualization of elements of technology for obtaining a tool;

- change control by processing methods;

- operations management;

- providing access to data;

- reconciliation of data by e-mailsignatures;

- quality control;

- ensuring the functioning of the smart search mechanism;

- variability of display types, etc.

As you can see, the number and content of functions is sufficient to obtain comprehensive information for a complete analysis of the process under consideration.

Technical Guide Builder

Working with documentation regarding the operation of complex systems. It is based on international requirements that regulate the issues of logistical support for products. The key idea of the standard is to work with a set of information units. The main concept is documentation modularity. Information is fragmented using special codes. Scope - any type of transport, military equipment, equipment.

Flexible adaptation to changing conditions is provided. The complex is suitable for both parent enterprises and related enterprises (manufacturers of materials, components).

LSA Suite

Is a set of procedures that implements the logistics support of production systems in time. Allows you to solve a number of problems, such as determining the reliability of the criticality of failures, creating a functional model of maintenance, determining the required number of spare parts.

ATLAS

A specialized platform designed specifically for processing data on the operation of technical aviation systems. The specified safety is ensured by constant monitoring of the state. The analysis carried out and subsequent upgrades make it possible to significantlycost savings.

Usage examples

CALS-technologies in Russia are used by many domestic enterprises, both civil and military sectors. Electronic documentation is used for many products. For example, in aviation for airplanes, helicopters, aircraft engines and components. In addition, development of navigation systems, telephone and radio communications, and control systems is underway. They are used in the design and development of automotive equipment. Elements of the system are used at the Voronezh Mechanical Plant, the state corporation "Rosatom", NPP "Aerosila", OJSC "Russian Railways" and others. As you can see, examples of CALS technology are quite diverse.

Conclusion

Management of CALS-technologies is an actual and modern task facing organizations. In the era of total informatization, the presence of local and global information spaces is a key development strategy. CALS standards, based on a variety of software systems, are the basis for the creation of modern high-tech products produced by automated production systems.

The time has come for fundamentally new elements of the organization of production, which are based on end-to-end management processes and the introduction of automated workplaces in the design and technological environment. And although the transition from outdated technological equipment to machine tools with numerical control andmulti-axis machining centers (and these are all CALS-technologies) requires enormous intellectual, material and financial costs, all enterprises that want to meet the spirit of the times must go this way.

Recommended:

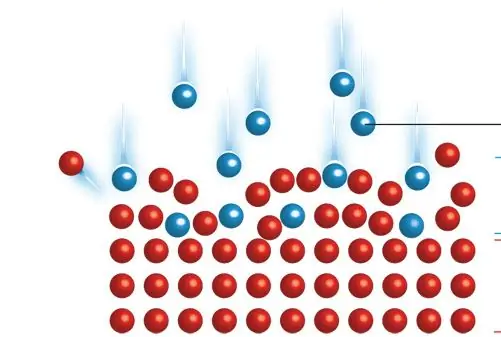

Ion implantation: concept, principle of operation, methods, purpose and application

Ion implantation is a low-temperature process by which the components of a single element are accelerated into the solid surface of a wafer, thereby changing its physical, chemical or electrical properties. This method is used in the production of semiconductor devices and in metal finishing, as well as in materials science research

Mineral wool density: classification, advantages and disadvantages, purpose of mineral wool and application

Mineral wool is the most popular type of insulation for an apartment or house. Today it is used by everyone, from builders to the owner of the apartment, who wanted to insulate the room. The simplicity of its installation allows you to immediately insulate the entire house (ceiling, walls, floor). We will study the features and characteristics of the named material further in the article

Equipment for agriculture: classification and types, purpose and application

Modern industry produces a variety of equipment for agriculture. It can be, for example, soil-cultivating equipment, as well as fodder, harvesting or sowing. Of course, tractors are also widely used on farms

Reinforced concrete is Concept, definition, production, composition and application

One of the most popular building materials is reinforced concrete. These are durable slabs that are used during the construction of high-rise buildings. The material is able to withstand significant loads. It is not subject to the destructive influence of external adverse factors. Features of reinforced concrete, its production technology and application will be discussed in detail in the article

What is a watermark: concept, need for application to documents, purpose

Everyone knows what a watermark is. The most common option is watermarks on banknotes. Such watermarks, which are visible only in the light, were placed on nominal paper, stamps, and in the modern version - on multimedia products. Despite the rather large age of this technique, it is still the most effective way to protect banknotes around the world today