2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:39

Recently, when arranging pipelines, perforated corrugated pipes are used, which have stiffeners and many small holes. These products, when compared with analogues of polyethylene pipes, have a huge number of advantages.

Why choose plastic pipes

The groundwater drainage pipe can be pottery, asbestos-cement or ceramic. Pottery and ceramic products were used in the process of agricultural development of territories. However, these pipes have many disadvantages, they are the need for frequent flushing, as well as a minimum service life. Among other things, such products contribute to the cost of use. Before installation, cuts were made in the body of asbestos-cement pipes, which harmed human he alth and increased the complexity of the process.

The use of asbestos-cement and ceramic perforated pipes was gradually abandoned due to theirlarge weight, which complicated the installation process. Their service life can reach 30 years, and installation work requires special skills. If you do not have certain knowledge, then the work on arranging the drainage system using ceramic and asbestos-cement pipes will take a long time. It is almost impossible to independently perform high-quality drainage using these products on your site, since manual perforation will let through small parts of soil and sand, which will lead to a rapid clogging of the system.

Additional advantages of plastic pipes

Such products are ready to serve for about 60 years, they have high qualities of durability, and also cost quite little. In order to save money, you can not resort to outside help. The presence of various standard sizes of polymer products allows you to build drainage systems with high productivity.

Plastic drainage pipe features

If you need a drainage pipe, it is best to choose a product that is made of plastic, as it has a number of advantages, including long service life, impressive strength, no corrosion processes, and ease of installation. The stiffening ribs, which are evenly distributed throughout the pipe, contribute to the fact that the products undergo various kinds of impacts and loads. Such pipes are very resistant to adverse conditions, namelylow temperatures and aggressive environments. Among other things, they are easy to transport and are flexible when laying.

During installation, the use of compensating elements is not required, and the pipes are connected using plastic fittings. The plastic drainage pipe has an excellent self-cleaning ability, which is guaranteed by the smooth inner walls. According to users, such pipes are characterized by a successful combination of price and quality. If you use polymer pipes for the drainage system, then the water supply pays off in the shortest possible time. This has been achieved through efficient system operation, low maintenance and ease of installation.

For reference

Drainage pipe can be laid up to 6 meters deep. The presence of a huge number of holes contributes to the fact that such pipes effectively collect liquid and quickly pass it, removing water from the site. The latter have a special profile. Some craftsmen make perforated pipes on their own using a conventional drill. But if it is necessary to use a pipe with a filter when laying the system, then it is better to prefer finished products.

Varieties of plastic drainage pipes

Plastic drainage pipe can have different base materials. In the manufacture of pipes, polyvinyl chloride, propylene, and high-pressure polyethylene can be used. Products may have differentexecution options. For deep laying in the ground, a double-walled pipe is suitable, which has improved strength qualities. For places where clogging and silting with small particles is possible, it is recommended to use a drain pipe with a filter. A large diameter groundwater drainage pipe is used when a large volume of liquid needs to be drained.

Installation recommendations

Work begins with the preparation of a trench, along the bottom of which a width equal to the diameter of the pipeline should be selected. To this value must be added 40 centimeters. In cross section, the pit may have a rectangular or trapezoidal shape. At the bottom there should be no hard lumps, broken bricks, sharp objects and stones that could push through the bottom wall of the pipe. If you will be laying a drainage pipe, it is recommended to consider a photo of the product in advance, this will allow you to understand which variety to choose. At the next stage, sand is poured into the trench, and after that - a layer of rubble. Its thickness should not be less than 20 centimeters, and the pipes for drainage are laid on top.

Work methodology

The top of the pipe should be backfilled with a layer of crushed stone, the height of which should be 20 centimeters or more. Next comes a layer of sand, and the outer part of the soil is laid with turf. When a pipe for groundwater drainage is mounted, it is recommended that the master consider the photo. This will eliminate manyerrors.

You should consider that the sequence of layers is an important factor. Sand is drawn to the water, not gravel. The laid pillow acts as a filter that allows you to maintain the desired slope. Crushed stone and sand, which are poured from above, act as a filter layer and protect the pipe from mechanical damage. Plastic pipes must be laid to a depth that is below the freezing level of the soil. This requires a slope of 3 degrees or more.

When a pipe is laid for drainage under a road or on the territory of a site for any purpose, it is important to provide for manholes. They should be located on straight sections with a distance of 50 meters from each other. Their presence is important in places where there will be turns, angle changes and intersections.

Installation rules

HDPE drainage pipe with perforation in the filter is necessary to prevent clogging of the system with debris, leaves and large particles. If you decide to carry out the laying of these elements, it is important to plan the site and find the specific information that is most often requested from the local land department. Thus, it will be important to know the seasonal groundwater level, the volume of water that falls as precipitation, soil characteristics and soil structure.

On the prepared pillow, you need to lay a pipe wrapped with geotextile, and cutting parts, if necessary, is carried out with a conventional mounting knife. After laying the pipes, it is important to check the correct slope of them, for thiscraftsmen use a cord stretched along the pipeline. Inspection wells must be equipped with covers, which will exclude debris from the structure. If the groundwater drainage pipe is not laid at an insufficient depth, this may cause an imbalance in the water balance. It is important to ensure the correct angle of inclination of the elements, if the above rules are neglected, the functioning of the structures may be disrupted, which will lead to problems with the water regime.

For reference

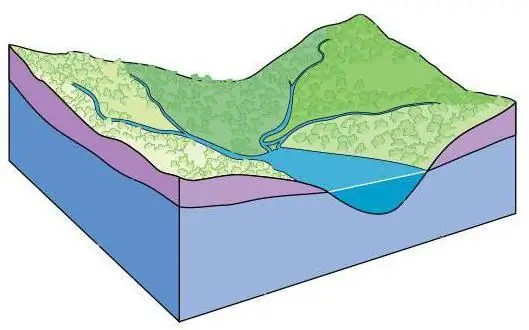

Drainage hoses are laid in the shape of a herringbone, which is considered the most common way. This node is necessary for conducting a network of pipes into a large collector pipe. The groundwater will go through the collector to a roadside ditch or storm sewer. If the liquid discharge point is located above the site, then a drainage well will need to be installed, water will be removed from it using a pump.

Cost of drainage pipes

After visiting the store, you can pick up a drainage pipe, which can cost 70 rubles. minimum. Depending on the diameter, type and type, as well as the number of purchased products, the price may vary up to 4000 rubles. The cost of a double-walled pipe, the diameter of which is 110 millimeters, is 75 rubles. However, even the same product sometimes has a different price.

Recommended:

Detailed photo studio business plan. How to open a photo studio?

A good photograph is comparable only to a brilliant printed work that has not changed its content over the centuries, but at the same time every family wants to have it

Casaflex pipe: a flexible solution for heating systems

The Swiss trade brand CASAFLEX was created as a new technical solution based on the specific conditions for installing heating networks in the European part of the continent and reducing dependence on expensive energy sources. The trademark is owned by the Swiss company Brugg Rohrsystem AG, which is part of the holding group BRUGG Group. Today CASAFLEX is the leader in the technology of production of heat-insulated flexible pipes "Isoproflex" and "Casaflex"

Groundwater depth: methods for determining

Most houses have centralized water supply. But due to remoteness from the settlement or for other reasons, in some country cottages, it is not available at the dachas. The owners have to drill a well or equip a well

Drainage of the soil: concept, purpose, methods and methods of work

Irrigation and drainage of soils are very important measures aimed at improving the conditions for normal growth and development of plants. Most novice farmers do not have questions about high-quality irrigation, but not everyone knows what drainage is. So why do you need to drain the soil, in what cases to do it, how to properly carry out this procedure and what it will give

Pre-insulated pipe: description, characteristics, application, photo

Pre-insulated pipes are often used in our country for the assembly of pipelines intended for the transportation of oil and gas. Also, such products can be used for the installation of centralized heating household networks and water pipes