2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

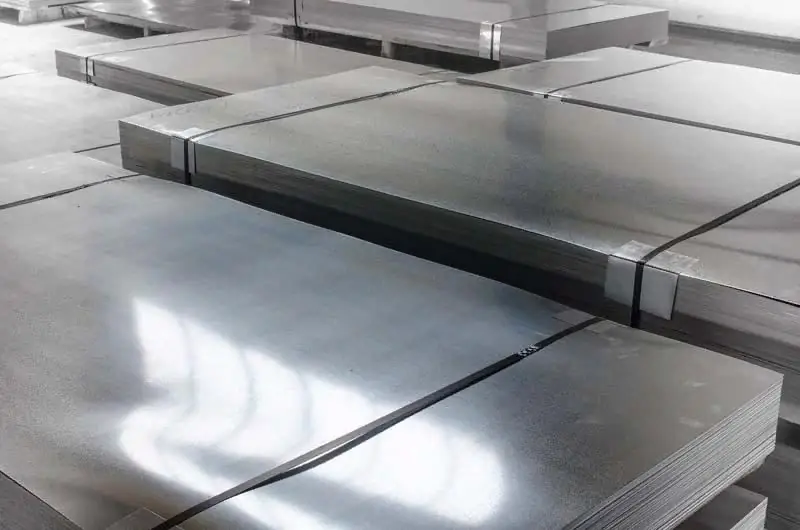

C245 is a steel grade belonging to the class of low-carbon structural alloys for widespread use. You can meet it at enterprises closely associated with the manufacture of metal structures of various types and purposes.

According to GOST 27772-88, in the name of the steel grade, the letter "C" stands for "Construction", and the following numbers indicate the ultimate yield of steel, measured in megapascals. It is easy to guess that C245 steel is intended for the manufacture of various kinds of metal products by shaped and hot-rolled products. Typically this is:

- corners;

- channels;

- beams;

- I-beams.

Steel C245: GOST

Even if the C245 alloy does not have any pronounced distinctive properties, however, even such a seemingly simple, judging by its application, steel has a ligature composition clearly prescribed in GOST. It does, however, somewhat affect the characteristics of the resulting product. That is why you should clearly know what impurities are present in the composition in order to better understand what C245 steel is capable of. And it contains suchitems like:

- Carbon is the most important additive. After all, it is she who turns soft iron into steel, making it harder, but thereby increasing fragility. Therefore, in order to maintain ductility, the carbon content in C245 steel is limited to 0.22%.

- Manganese is one of the most common additives that increases the resistance of steel to environmental influences. Its content is not more than 0.65%.

- Silicon, which increases the ductility of steel and improves its internal structure, is contained in the alloy in an amount of up to 0.15%.

- Chromium is a common alloying additive that increases the resistance of steel to corrosion, and also slightly increases strength. However, in C245 steel, the chromium content is limited to 0.30%, and therefore its effect on steel is not so significant.

- Nickel is an element that has a complex effect, as it increases both the strength, ductility and corrosion resistance of steel at once. Its percentage in the alloy is equal to the content of chromium.

- Copper is an alloying additive that is inherent in most building steels and increases their resistance to corrosion. Steel C245 contains 0.30% copper in its composition.

In addition to the above additives, the composition contains harmful impurities of sulfur and phosphorus. However, their impact on quality is negligible.

C245 specifications

For any structural steel without exception, the following indicators remain the main ones:

- strength;

- weldability;

- resistance toenvironmental impact.

Analysis of each item

Steel C245, mainly due to its composition, does not have outstanding strength indicators. However, it must be understood that such requirements have never been presented to her. Its direct purpose is to be ductile, which makes it possible to produce the necessary parts from sheet steel by cold stamping, as well as by simple bending. For thicker material, it is recommended to use heat at the fold.

C245 is an excellent choice for welded structures as the weldability of the alloy is unlimited and the resulting joint is not prone to defect formation.

Regarding corrosion resistance. Since the steel contains impurities of nickel, chromium and copper, resistance to its effects becomes more noticeable. This allows you to store steel products for a long time without any problems, without resorting to, for example, applying a protective varnish / paint coating. However, for long-term storage, a dry room is still preferable.

Recommended:

Food stainless steel: GOST. How to identify food grade stainless steel? What is the difference between food stainless steel and technical stainless steel?

The article talks about grades of food grade stainless steel. Read how to distinguish food stainless steel from technical

Steel 3: GOST, ligature and characteristics

In today's industry, few steel grades will be as popular as steel 3. Although it does not have any special properties, it is nevertheless universally used in large volumes in any enterprise, even partially associated with using metal structures and rolled products. So what's the deal?

Steel 20: GOST, characteristics, properties and applications

Structural steel is the most demanded in the gas and oil industry, housing and communal services, at the household level. Versatile features, low cost and proven reliability and practicality are of great interest to manufacturers

Corrosion resistant steel. Steel grades: GOST. Stainless steel - price

Why metal materials break down. What are corrosion-resistant steels and alloys. Chemical composition and classification according to the type of stainless steel microstructure. Factors affecting pricing. Steel grade designation system (GOST requirements). Application area

440 steel - stainless steel. Steel 440: characteristics

Many people know 440 steel. It has established itself as a reliable, anti-corrosion, time-tested hard material, which is most often used for the manufacture of knives for various purposes. What is the secret of this alloy? What are its chemical, physical characteristics and applications?