2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

Metal is the basis of all modern civilization. In a year, modern humanity extracts and processes such an amount of iron alone that before the whole world would pick it for at least a couple of centuries. And this need is fully justified, since the construction alone takes an incredible amount of steel. It is not surprising that metal casting in such conditions is constantly being improved.

A bit of history

The most important feature of iron to take, freezing, "proposed" form, a man noticed in ancient times. Today, almost all scientists assume that the initial acquaintance of man with metal took place thanks to meteorites. Meteoritic iron was fusible and easy to process, so the basics of casting were studied by some nascent civilizations a long time ago.

In our country, metal casting has been a respected and honorable business for centuries, people have always treated this craft with great respect. The "Tsar Cannon" and "Tsar Bell" are widely known, which are masterpieces of the casting skill of Russian masters, even if one of them never rang, and the second did not shoot. Ural casters in the reign of Peter the Greatgained particular fame as a supplier of reliable weapons for the army. However, they quite rightly carry this title even now. Before we look at the main types of metal casting, it is necessary to say a few words about the required characteristics of raw materials.

What should be the metal for casting

The most important property of the metal to be used for casting is its fluidity. The alloy in molten form should flow as easily as possible from one crucible to another, while filling its smallest recesses. The higher the fluidity, the thinner the walls can be made in the finished product. With metal that does not flow well, it is much more difficult. Under normal conditions, he manages to grab much earlier than he fills all the gaps in the form. This is the difficulty industrialists face when casting metal alloys.

It's no surprise that cast iron has become the foundry's favorite material. This is because this alloy has excellent fluidity, making it relatively easy to work with. Steel is far from being so fluid, and therefore, to completely fill the mold (so that there are no cavities and voids), one has to resort to a variety of tricks.

In the simplest case, when home metal casting is required, the raw materials are melted and poured into water in small portions: this is how, in particular, you can make sinkers for fishing. But this method is relatively widely used even in the arms industry! From the top of a special tower, resembling a cooling tower in outline, moltenmetal. The height of the structure is such that a perfectly formed droplet, already cooled down, reaches the ground. This is how shot is produced on an industrial scale.

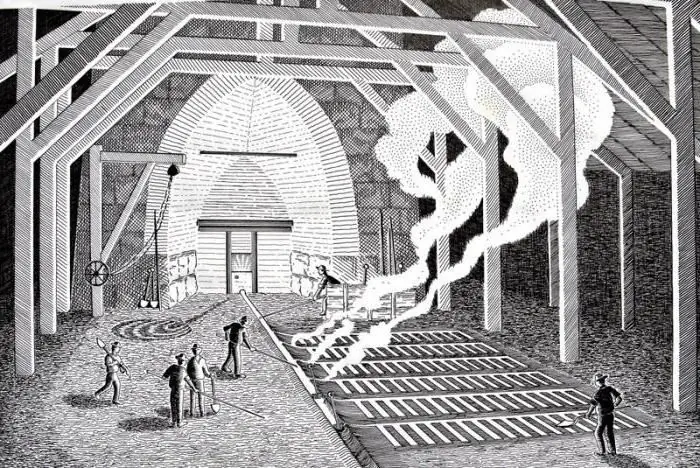

Earth casting method

The most simple and ancient method is casting metal into the ground. But its “simplicity” is a relatively conditional concept, since this work requires extremely painstaking preparation. What does it mean?

First, a full-sized and most detailed model of the future casting is made in the model shop. Moreover, its size should be somewhat larger than the product that should be obtained, since the metal will settle when cooled. As a rule, the model is made detachable, from two halves.

Once this is done, the special molding sand is prepared. If the future product should have internal cavities and voids, then it will also be necessary to prepare the rods, as well as an additional molding composition. They must temporarily fill those areas that are “empty” in the finished part. If you are interested in casting metals at home, be sure to keep this fact in mind, because otherwise an already filled flask can simply be torn apart by pressure, and the consequences of this can be the saddest.

What are molding sands made of?

The basis is various grades of sands and clays, as well as binders. Their role can be played by natural and synthetic oils, drying oil, resin, rosin, and even tar.

Next comes the time of the molders, whose task is to make molds. If you explaineasier, it is done like this: a wooden box is taken, a half of the mold is placed in it (it is also detachable), and the gaps between the walls of the model and the mold are clogged with a molding composition.

The same is done with the second half and fasten both parts with pins. It is important to note that two special cones are inserted into that part of the form that will be at the top when poured. One of them is used to pour molten metal, the second - to exit expanding gases.

End of preparatory phase

And now it's time for perhaps the most crucial part of the operation. The flasks are very carefully separated, trying to prevent violation of the integrity of the sand. After that, two clear and detailed imprints of the future part remain in the ground. After that, they are covered with a special paint. This is done so that the molten metal does not come into direct contact with the sand ground. Metal casting technology should not allow this, otherwise the quality of the finished product may deteriorate significantly.

If this is necessary, at the same time an additional gating passage is cut, which is necessary for pouring the melt. The flasks are again folded and connected as firmly as possible. Once the sand is slightly dry, you can start casting.

Start casting

First, in cupolas, that is, special furnaces, cast-iron blanks are melted. If it is required to cast steel, then the raw materials are melted in blast furnaces, open-hearth, inverter and other furnaces. To bring inmelt state of non-ferrous metals, use specialized melting devices.

Everything, you can start casting. If there is only one form, then the melt is poured into it with a ladle, individually. In other cases, as a rule, a conveyor is organized: either a belt with blanks goes under the ladle, or the ladle moves over the rows of flasks. It all depends solely on the organization of production. When the time comes and the metal cools down, it is taken out of the mold. In principle, this method is ideal in cases where metal casting is required at home (for a forge, for example). Anything more perfect under such conditions will not be achieved anyway.

Sandblasting or grinding machines remove scale and adhering molding sand from the finished product. By the way, this method was actively used in the production of tanks during the Great Patriotic War. This is how cast towers were produced, and the simplicity and manufacturability of this process made it possible to produce a huge number of military vehicles that the front needed so much. What other types of metal casting exist?

Die casting

But now they use much more advanced and technologically advanced methods for the production of cast products. For example, metal casting in a chill mold. In principle, this method in many respects resembles the one described above, since in this case casting molds are also used. Only at the same time they are metal, which greatly simplifies the process of large-scale production.

So, cones and rods are inserted into two halves (for pouring metal and forming voids), andthen firmly fasten them to each other. Everything, you can get to work. The peculiarity of this method is that here the molten metal solidifies extremely quickly, there is the possibility of forced cooling of the molds, and therefore the release process is much faster. With just one mold, you can get hundreds, if not thousands, of castings, while not spending a lot of time on individual preparation of molds and sands.

Some disadvantages of the method

The disadvantage of this casting method is the fact that only those types of metals that are characterized by increased fluidity in molten form are suitable for it. For example, only pressure casting is suitable for steel (about it below), since this material does not have good fluidity at all. Under the action of compressed air, even the most "ductile" grades of steel take the required shape much better. The bad thing is that an ordinary chill mold simply cannot withstand such extreme production conditions and will fall apart. Therefore, you have to use a special production method, which we will discuss below.

Injection molding

How is die casting - under pressure - of metals carried out? We have already considered some aspects above, but it is still necessary to disclose this issue in more detail. Everything is quite simple. Firstly, a casting mold made of quality steel grades is needed, which can be a multi-stage, complex internal shape. Secondly, we need pumping equipment capable of delivering from seven to seven hundred MP.

Main advantagethis smelting method is a high productivity. What else provides injection molding? In this case, much less metal is used, and the surface quality of the finished product is very good. The latter circumstance implies the rejection of a complex and rather dreary cleaning and grinding procedure. What materials are the best materials for this production method to produce finished products and parts?

The most commonly used alloys are based on aluminum, zinc, copper and tin-lead (casting of non-ferrous metals). Their melting temperature is relatively low, and therefore a very high manufacturability of the entire process is achieved. In addition, this raw material has a relatively small sediment upon cooling. This means that it is possible to produce parts with very small tolerances, which is extremely important in the production of modern technology.

The complexity of this method is that when the finished products are separated from the molds, they may be damaged. In addition, this method is only suitable for the manufacture of parts with a relatively small wall thickness. The fact is that a thick layer of metal will harden extremely unevenly, which will predetermine the formation of shells and cavities.

Varieties of installations for pressure casting

All machines that are used in this method of casting metal products are divided into two large groups: with a hot and cold casting chamber. The "hot" variety can most often only be used for zinc-based alloys. In this case, the casting chamber itself is immersed in hot metal. Under pressureair or a special piston, it flows into the casting cavity.

As a rule, a strong injection force is not required, pressure up to 35-70 MPa is enough. So, in this case, metal casting molds can be much simpler and cheaper, which has the most favorable effect on the final cost of the product. In cold casting molds, the molten metal has to be "driven" deep into the casting chamber under particularly high pressure. At the same time, it can reach 700 MPa.

Where are injection molded parts used?

They are everywhere. In phones, computers, cameras and washing machines, everywhere there are parts obtained using this particular method. It is especially widely used by mechanical engineering, including those directly related to the aviation and even space industries. The mass of cast parts can vary from a few grams to 50 kilograms (and even higher). Can some other "processing" of metals by casting be used? Yes, and there are many more ways.

Lost wax casting

As in the very first case we considered, since ancient times mankind has known about the method of pouring molten metal into a pre-prepared model made of paraffin or wax. It is simply placed in the flask and the gaps are filled with molding sand. The melt dissolves the wax and ideally fills the entire volume of the primary blank. This method is good because the model does not need to be taken out of the flask. In addition, it is possible to obtain parts of simply perfect quality, this casting processmetals are relatively easy to automate.

Shell casting

If the casting is relatively simple, and "space" strength from the finished product is not required, the method of casting into shell molds can be used. They have been made since time immemorial, and fine quartz sand and resin are used as the basis. Today, of course, various synthetic compounds are used as the latter.

Then, collapsible metal models are taken, consisting of two halves, and placed on a surface heated to approximately 300 degrees Celsius. Then the molding mixture (from sand and dry resin) is poured into the same place so that it completely covers the surface of the metal models. Under the influence of heat, the resin melts, and a rather strong “flask” appears in the thickness of the sand.

As soon as it all cools down a little, metal ingots can be removed, and the sand can be sent to the oven for “roasting”. After that, sufficiently strong forms are obtained: by connecting their two halves, molten metal can be poured into them. What other metal casting methods are there?

Centrifugal casting

In this case, the melt is poured into a special form, which rotates at a very high speed in a horizontal or vertical projection. As a result of the action of powerful equally applied centrifugal forces, the metal flows evenly into all gaps of the mold, thereby achieving a high quality of the finished product. This casting method is ideal for the production of various types of pipes. It allows forming a much more uniform thicknesswalls, which is extremely difficult to achieve using "static" methods.

Electro-slag casting

Are there any ways of casting metals that can rightly be called modern? Electroslag casting. In this case, the liquid metal is first obtained by acting on the previously prepared raw material with powerful electric arc discharges. The arc-free method can also be used, when iron is melted from the heat accumulated by the slag. But the last one is affected by powerful discharges.

After that, the liquid metal, which has never come into contact with air throughout the entire process, enters the crystallization chamber, which "in combination" is also a casting mold. This method is used for relatively simple and massive castings, for the manufacture of which many conditions do not need to be observed.

Vacuum filling

Only applies to "high-end" materials such as gold, titanium, stainless steel. In this case, the metal is melted under vacuum conditions, and then quickly (under the same conditions) is distributed into molds. The method is good in that when it is used, the formation of air cavities and cavities in the product is practically excluded, since the amount of gases present there is minimal. It is important to remember that the weight of the castings in this case cannot exceed a hundred or two kilograms.

Is it possible to get larger parts?

Yes, such technology exists. But it can only be used in cases where one hundred tons of steel is processed at the same time.and more. First, the metal is melted under vacuum conditions, and then it is poured not into molds, but into special molding ladles, which are also protected from air entering their cavity.

After that, the finished melt can be distributed into molds, from which the air was also previously pumped out with a pump. The steel obtained as a result of such a technological process is quite expensive. It is used for forging, as well as some types of the same casting, when it is required to obtain blanks and parts of the highest quality.

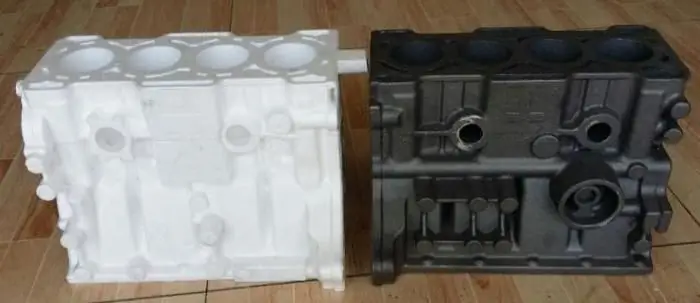

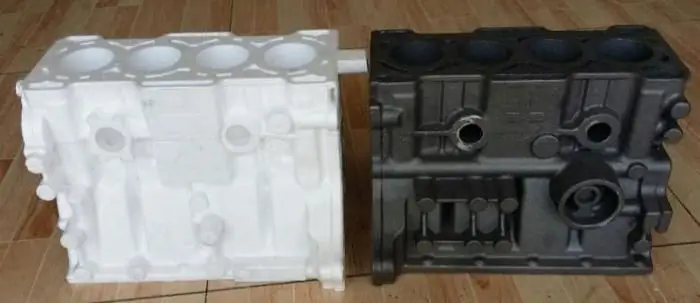

Casting on gasified (burned out) patterns

In terms of casting quality and simplicity, this method is one of the most profitable, and therefore it is used more and more widely in modern industry. Such metal casting, the production of which is increasing year by year, is especially popular in the PRC and the USA, since the industrial bases of these two countries are distinguished by the greatest need for high-quality steel. The advantage of this method is that it allows castings to be produced without any weight or size restrictions.

In many ways, this method is similar to those described above: for example, in this case, the primary model is used not from wax or plasticine, but from the now widespread foam. Since this material has its own specifics, the binder sand mixture is packed into the flask under a pressure of about 50 kPa. Most often, this method is practiced in cases where it is necessary to make parts weighing from 100 grams to two tons.

However, we have already said that some strict restrictions onsize details no. So, using this casting method, even components for ship engines can be produced, which have never been “modest” in size. For each ton of metal raw materials, the following amount of additional materials is consumed:

- Sand quartz fine - 50 kg.

- Special non-stick coating - 25 kg.

- Granulated polystyrene foam - 6 kg.

- Dense polyethylene film - 10 sq. m.

All molding sand is pure quartz sand without any additional additives and additives. It can be about 95-97% reusable, which greatly improves the economy and reduces the cost of the process.

Thus, metal casting (the physics of the process was partially considered by us) is a “multifaceted” phenomenon, since today there are a lot of new methods. At the same time, modern industry is applying methods that have been in use for several thousand years ago, somewhat adapting them to current realities.

Recommended:

How sheep are sheared: methods, timing, preparation of the animal, description of the process

Sheep wool is a quality natural material. Its properties are unique, it has no analogues. The history of the development of mankind shows that since ancient times people have used sheep wool for various needs. It was and is received by shearing sheep's hair

Process engineer: job description. Process Engineer: Job Responsibilities

The job description of a process engineer is an addition to the employment agreement and defines the duties, rights and degree of responsibility of the person applying for the specified vacancy. This administrative document is intended to specify the powers of the administrative apparatus in relation to the specialist technologist, as well as to designate the functions of an employee

Hot galvanizing. The process of galvanizing metal products

The article is devoted to hot-dip galvanizing technology. Its features, technological stages, pros and cons, cost, etc. are considered

Casting in silicone mold: equipment. Vacuum casting in silicone molds

For the manufacture of a small number of plastic blanks, vacuum casting into silicone molds is most often used. This method is quite economical (making a metal mold requires more time and money). In addition, silicone molds are used repeatedly, and this also significantly reduces the cost of production

Restoration of parts by welding and surfacing: methods and methods of restoration, features, technological process

Welding and surfacing technologies allow efficient restoration of metal parts, providing a high degree of reliability and durability of the product. This is confirmed by the practice of using these methods when performing repair operations in a variety of areas - from car repairs to the production of rolled metal. In the total amount of work on the repair of metal structures, the restoration of parts by welding and surfacing takes about 60-70%