2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:25

Sheep wool is a quality natural material. Its properties are unique, it has no analogues. The history of the development of mankind shows that since ancient times people have used sheep wool for various needs. It was and is being obtained by shearing sheep's hair.

General characteristics of the rune

Sheep wool is considered the most valuable product of sheep breeding. The breeds of these animals are usually divided into fine-fleeced, semi-fine-fleeced, coarse-haired, semi-coarse-haired. Modern methods of shearing sheep produce excellent quality wool, which is much more in demand than sheep meat.

Fine-wool and semi-fine-wool sheep breeds are the sources of the fleece most demanded by the light industry (fleece - sheared sheep wool). Representatives of these breeds are sheared only once a year. An important condition is the establishment of the fact - the sheared wool will have a length of 3-3.5 cm.

Currently, the most common source of quality fleece is merino sheep,a fine-fleece breed bred in Spain back in the 12th century, which ensured the prosperity of this state for two whole centuries.

Choice of cutting period

Sheep shearing is usually done in the spring. Young animals born in the winter (January to March) are usually sheared in the summer, maintaining the parameters of the coat length standard.

Sheep shearing in the spring time is varied. It is directly dependent on the climatic zone, the condition of the sheep, their wool. In the southern regions, sheep are sheared in late April - early May. In other latitudes, the procedure is usually postponed to mid-late May, when warm weather sets in.

The main parameters of the beginning of the shearing is the amount of grease (grease is a fat-like substance contained in sheep's wool, which is formed due to the combination of secretions from the sweat and sebaceous glands of the animal). In winter, sheep fat is not enough, as a result of which their wool is stiff and dry. Therefore, it is necessary to wait for the fleece to acquire softness and elasticity, allowing you to maintain the optimal condition of the wool cover when shearing sheep.

However, they try not to delay the deadlines. With the onset of warmer, hotter weather, burdock and other herbs appear on pastures, which cling to the hairs of sheep's wool. The process of their removal is quite laborious, and the quality of the cut material is reduced.

Cutting of certain breeds

Sheepsemi-coarse-haired and coarse-haired breeds molt in the spring. Therefore, sheep breeders must be careful to establish when they will begin the process of twirling (twisting is the thinning of woolen hair). This is the best time, the shearing process is quite simple, the fleece is separated without much effort.

Coarse-wooled sheep are sheared twice a year, semi-coarse-wooled - 3-4 times a year. Sheep of these breeds must be rid of wool, even if it is of poor quality and cannot be used. Otherwise, they will suffer from hot weather, which will lead to a deterioration in appetite, a delay in gaining mass.

Coarse-wooled and semi-coarse-wooled breeds are sheared in the same way as fine-fleeced sheep are sheared, according to the same rules.

Lambs are sheared for the first time when they are 4-5 months old.

How do they cut their hair?

Since ancient times, sheep have been sheared by hand. Ancient sheep breeders used special scissors for this. Their form has remained virtually unchanged to this day. Their distinctive feature is a comfortable handle for gripping by hand. At the same time, their shearing is not fast, but high-quality, with minimal injuries to sheep. What's more, the blades on these scissors are easy to sharpen.

And at present, in those farms where flocks of sheep are small, manual labor is preferable. However, large herds require the use of mechanized shearing methods, which involve the use of special clippers.

Process

It is customary to shear sheep inseparate room. It should be dry and light. Prepared special flooring, tables, confused tarpaulin to prevent loss of wool.

The haircut process is carried out in a certain sequence, in several stages:

- the animal is placed with its back to the master on the left side;

- sheep body surface is rid of dirt;

- then cut off the tails, making passes around the udder, the nipples are covered with hands. Then, shreds of wool are removed from the inner surface of the thighs and legs, which are deposited separately;

- in one pass, a continuous strip of wool is removed between the right pair of legs and inguinal folds. In this case, they usually move from the back to the front;

- sheep's chest and belly are cut with longitudinal lines that start from the lower belly or from the udder;

- then the animal is turned over to the other side. The master becomes facing his stomach, and the croup is subjected to a haircut with a gradual movement to the left shoulder blade;

- further with continuous longitudinal passages shear the withers, side surface, lower back. All movements go to the spine. The sheep is fixed so that the sheared wool under the action of gravity itself falls to the floor;

- then the sheep is again laid on its side, left, while the master changes his position, facing the animal's stomach;

- after that, they cut out the right shoulder blade, croup, completely right side, back through long longitudinal passes;

- further haircut is subjected to the head, neck on the right side, perpendicular to the spine. Raising my headprocess its left side;

- the resulting rune layer is moved away from the ram.

At the end of the process, the sheep is put on its feet and escorted outside the shearing area.

Working with scissors is similar to machine cutting. However, when using the machine, it is necessary to ensure that its comb is always in contact with the skin, and does not linger in one place. Otherwise, cuts are formed, which reduce the quality of the rune.

Recommendations

Experienced haircutting father advises to use the recommendations and advice worked out in practice, which include the following:

- Sheep with the maximum degree of fatness are much easier to shear. Their fleece is well saturated with grease, the surface of the body is dense, even. Those sheep that are not well-fed have an uneven body relief, their wool is loose, dry.

- 1-2 months before the start of the haircut, it is recommended to carry out a preliminary haircut. It is designed to clean the fleece from dirt, contributes to less time later, during the main haircut. A preliminary procedure is also recommended in order to ensure the safety of the machines. It minimizes their sweat work with complex hair, resulting in damage to parts. Those who shear sheep with scissors save themselves the need to sharpen them frequently.

- Before shearing, sheep are not fed. Under the stress that animals are subjected to when shearing, gastrointestinal incidents are possible, which can lead toto serious consequences, volvulus and death. Animals must be kept without food for more than 12 hours before shearing.

- The sheared fleece must be spread on a flat surface, upside down, cleaned of dirt. It must be stored folded, avoiding contact between the inside and the outside.

- After the animals have been sheared, it is recommended to keep them close to indoor areas. Do not take them to a distant pasture so that they do not fall under inclement weather. Sheep are especially vulnerable after shearing. Sharp fluctuations in temperature, cold winds, precipitation can significantly harm her immunity.

Helpful tips

Experienced specialists, masters advise to be calm and confident before starting a haircut. Rams and sheep feel the mood of a person. If he is nervous, then the animal, sensing his condition, will begin to escape, twitch.

It is recommended to shear the ewes first, then the lambs (young ones are sheared in the same way as ordinary sheep are sheared), and finish the shearing with rams.

It is proposed to get two assistants before the haircut. The first is responsible for holding the animal, the second for collecting and sorting the wool. Moreover, teamwork greatly speeds up the process, makes it easier.

Animals that will be slaughtered for meat should be rid of hair two to three months before slaughter. They are sheared in the same way as sheep that are not intended for slaughter are sheared. This is done so that the wool grows back and the skin (sheepskin) removed from the slaughtered animal retains its fur qualities.

Before shearing, sheep are examined to determine the order. Animals whose fur is wet are placed in conditions that will ensure that it dries.

A mandatory condition for the places where the haircut will take place is the absence of drafts. Animal wound care products should be placed near the cutting area.

If the process will take place in an open area, then it should be on a hill, with no drafts. The earth must be covered with a dense cloth (tarpaulin). It is advisable to equip it with a canopy to protect it from direct sunlight.

Ways to cut

As noted above, sheep are sheared in two ways: manually - using special scissors; mechanical - using clippers.

The first method is stretched in time. However, the shearer can cut the wool as close to the skin as possible, increasing its length.

Using a mechanical method (manual clipper) greatly facilitates work, increases productivity. The fleece is cut evenly, the animal suffers less. However, before that, the machine must be properly adjusted, check the edge of the knives and treat with an antiseptic.

There are two types of sheep shearer - mechanical and electric. The first is the same scissors, which have improved blades and a comfortable handle. Electric is similar in shape to the machine that cuts human hair.

Currently, electric cars are preferred becausemechanical devices are considered disposable, break more often. They speed up the haircut process a little.

Choosing an electric machine

In order to choose the optimal electric sheep clipper, you need to get an idea of the parameters. Properly selected devices are able to cope with woolen tangles, eliminate shortcomings in work. When purchasing them, it is recommended to pay attention to the following characteristics:

- Power. This parameter is important if you have to cut a large herd. Power determines the speed of work, the number of sheep to be processed in one session. If the livestock is up to 50 sheep, then devices with a power of up to 220 watts are usually suitable. More powerful ones are expensive and do not always pay off. A machine with a power of 320 W and above is purchased for large farms. Manufacturers on packages, in product instructions indicate how many animals can be processed in one season.

- Warranty period. The manual sheep clipper is not a consumer product. This is a narrowly focused, piece goods. As a result, service centers that are able to service and repair them are difficult to find. Usually well-known brands give a guarantee for 12-18 months, which means at least 4-6 haircuts.

- Consumables and spare parts. Machines work in difficult conditions, sooner or later they will break down, fail. As a result, it is cheaper to replace a broken element than to buy a whole device. Some manufacturers, meeting the needs of consumers,produce the necessary, often failing spare parts.

- Service. Sheep clippers should be regularly cleaned, lubricated, and individual elements replaced. If the design is complex, then this implies contacting specialists in service centers. The simplicity of the device will allow you to maintain the device yourself, saving money and time.

- Fuses. During operation, overheating of the machine is not uncommon. If it is not equipped with an overload fuse, it is more likely to burn out.

- Sheep clipper knives. Their condition, the quality of the metal is the main characteristic of a sheep clipper. Blades should be serrated, sharp and straight. Improper sharpening will lead to injuries to sheep and damage to wool. If the manufacturer includes interchangeable knives in the delivery set, then this is an additional plus for purchasing this model.

- Noise level. Sheep are shy animals. A sharp noise can cause them to panic, which will be transmitted to the entire flock. It is very difficult to work with a twitching animal that intends to run away. It must be remembered that machines that emit sound up to 80 decibels are perceived as a quiet vacuum cleaner. Those that make sounds of 90 or more decibels are comparable to a running motorcycle engine. These are very likely to scare the sheep.

- Country of origin. According to the sheep shearers, the best producers are the USA, Russia, Germany, Switzerland. Currently, China also produces successful models. The reliability of all of them is confirmed by time. However, the cost of many devices is high,not always affordable. The price for quality devices starts from 15,000 rubles

Recommended:

Sheep is Animal description, breeding benefits, use in slang

Sheep: what kind of animal is this? What features does it have? The lifestyle of a ram and its average size. How do people make money raising sheep? Who are called "rams"? You will find answers to all these questions in the article below

Preparation of oil for processing: the main process, methods and technologies

Produced from the wells of oil fields are not a raw material in its pure form. Before the stages of the production process of the main processing with the receipt of a trade item with the necessary consumer qualities, the future energy resource goes through several technological stages of processing. The need for the implementation of these processes is due to the initial contamination of crude oil

Sheep breeding: business plan. Sheep breeding as a business from "A" to "Z"

It is not uncommon for start-up entrepreneurs living in rural areas, when choosing the direction of their activity, prefer to engage in sheep breeding. Raising sheep is traditionally a popular business

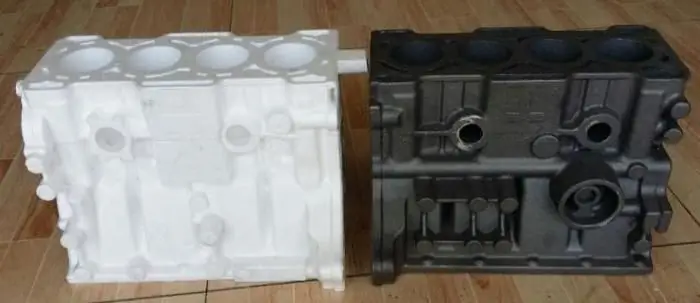

Metal casting: process, methods, methods

Metal is the basis of all modern civilization. In a year, modern humanity mines and processes such an amount of iron alone that before the whole world would have been digging it for at least a couple of centuries

Restoration of parts by welding and surfacing: methods and methods of restoration, features, technological process

Welding and surfacing technologies allow efficient restoration of metal parts, providing a high degree of reliability and durability of the product. This is confirmed by the practice of using these methods when performing repair operations in a variety of areas - from car repairs to the production of rolled metal. In the total amount of work on the repair of metal structures, the restoration of parts by welding and surfacing takes about 60-70%