2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

For the manufacture of a small number of plastic blanks, vacuum casting into silicone molds is most often used. This method is quite economical (making a metal mold requires more time and money). In addition, silicone molds are reusable, and this also significantly reduces the cost of production.

Plastic molding

The essence of the technique of casting plastics is as follows. The molten material is in the screw of the unit (special equipment for casting into silicone molds). Under the influence of the piston, the mass moves along the gate channels, then fills the mold space. In this way, a casting can be obtained. When plastic is heated, the atoms that make up it begin to move randomly and randomly. However, upon cooling, crystallization centers begin to form. At the walls of the form, crystals grow, then suchthe process also takes place inside the casting. At this stage, it is very important to observe the temperature regime, to choose the right exposure time. Otherwise, molding plastics into silicone molds will be of poor quality, with visible traces of marriage. But, first of all, it is necessary to make the molds themselves, into which the mass for crystallization will be poured.

Technology for creating casting molds

There are several ways to create silicone molds. The first one is a solid fill. This method is suitable for simple designs: reliefs, souvenirs, two-dimensional parts. The model is placed in the formwork, filled with silicone. Detachable molds are made like the previous ones, used for more complex shapes. Two-part forms are produced in several stages. First, the first half of the workpiece is poured, after the silicone has hardened, the mold is turned over and the second part is made in the same way. With this method, it is very important to designate special locks on the base (casting in a silicone mold of this type should occur without displacement). Most accurately repeats all the details of the workpiece form "in spread". A fairly viscous silicone is applied to the part with a brush. The process takes place in several stages, this is necessary for the complete repetition of all the small nuances of the product. At the same time, the form itself is quite thin - from 3 mm. In order for it to hold its shape, an outer hard shell is created at the final stage.

Silicon for making molds

Vacuum casting insilicone molds involves the use of various materials to create matrices. One of them is Mold Star type silicone. It is applied to continuous filling, rather strong and flexible. Hardening occurs at room temperature. For the "spread" technique, the Rebound series is most often used. This silicone has a high viscosity, which can also be controlled using a thickener. Casting in a silicone mold of this kind allows you to get a high-quality, durable matrix, and, accordingly, an ultra-precise part. There are also translucent silicones that are ideal for cut shapes.

Casting materials

As a rule, polyurethane is used to make the parts themselves. The material has high impact strength, hardness, elasticity. Polyurethane rubbers have higher tensile strength, tear. They are used in the manufacture of various tapes, cylinders, dies, gaskets, bushings. Also, transparent plastic is used for casting. It is quite resistant to UV rays and retains its transparency even when stained. Scope - lenses for various tests, prototypes in medicine, the manufacture of souvenirs, etc. As a rule, molding in a silicone mold involves the use of two-component mixtures, which include directly plastic and a catalyst.

Molding plastic into silicone molds. Equipment

Small batch productioncast blanks is a technological process that allows you to get a batch of exact copies of a part of any complexity. Very often, the technique is used to obtain prototypes that are tested before the start of mass production, working out the appearance, design.

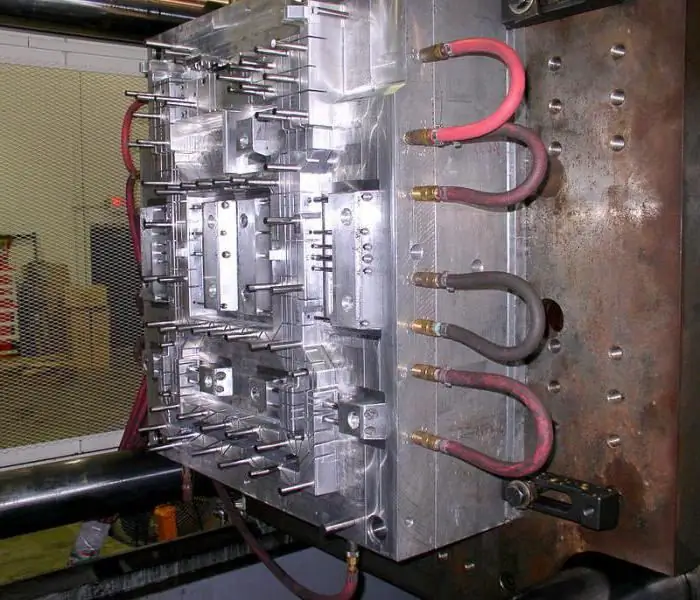

Industrial molding of plastic into silicone molds equipment includes the following: a vacuum chamber (injection molding machine), a heating cabinet, a vacuum mixer (mixer). Silicone is first prepared in a vacuum chamber, where the process of material degassing takes place. This is necessary to prevent the formation of bubbles on the form. After the mold has been made and preheated, the polyurethanes (or resins for the final part) are mixed directly. This process takes place in a vacuum chamber. Through the sprue, the mixture is poured into the mold. For final processing, it is necessary to place the workpiece in a special oven, where the final hardening of the product takes place at a temperature of 70 ° C.

Vacuum chamber. Key Features

Generally, the production scale uses automatic silicone mold casting. The equipment, namely the vacuum chamber, allows you to control both the temperature and the casting speed. The operator does not require special skills and knowledge, since all control comes from the operating system, which has both automatic and manual switching. There is also the possibility of editing a given program. Various camera modifications are capable of producingworkpieces up to 5 kg (for example, ST-02 camera). The unit is equipped with an elevator for lifting silicone molds. It should be noted that the ST-02 system allows the use of both small and fairly heavy matrices.

Another option is the MCP camera. This silicone mold casting equipment can produce parts with thin walls and complex configurations. This process is carried out due to differential pressure. Then the resulting casting is removed, and then it hardens in air. Vacuum casting into silicone molds for some types of plastics is completed in heating cabinets, which provide uniform heating of the air, and, accordingly, the workpiece.

Finishing the cast billet

After the plastic mass is completely hardened, it is carefully removed from the mold. The surface is machined, the protrusions are removed and cleaned, the irregularities are polished. If necessary, the workpiece is covered with either paint or other protective material. It is also necessary to clean the silicone mold, remove the remnants of plastic. Then it is washed, preparing for subsequent use. It is worth noting that molding plastic into silicone molds involves the repeated use of matrices (from 20 to 80 times).

Main advantages of the method

Small-scale production is developing dynamically, it allows you to qualitatively evaluate the sales market, test products, create unique author's works in a small amount. Siliconethe molds that are used in the injection of plastics make it possible to completely copy the texture, shape, and design of the workpiece. The part is easily released from the matrix, which, moreover, can be used repeatedly. Castings have a minimum number of surface defects, optimal physical and mechanical properties. In addition, in some cases, even metal can be poured into silicone molds.

But the main advantage that silicone mold casting has is the price. The providers of this service indicate that the final cost of the blank will depend both on the material of the plastic and on the volumetric parameters of the part (for example, a blank measuring 101010 cm can cost 1,500 rubles). Silicone itself can be purchased from 500 rubles per kilogram, plastic - from 700 rubles. The cost of metal forms is quite high, sometimes their use is simply inefficient (if the circulation is several units). And silicone matrices are also suitable for home use, it is not at all necessary to buy expensive equipment. One has only to make a layout on their own, take into account the lifetime of polyurethanes (the period when they remain liquid and suitable for pouring), observe all the technological nuances - and casting in a silicone mold can be done even at home. According to calculations, the cost of one blank in this case is about 70-140 rubles.

Recommended:

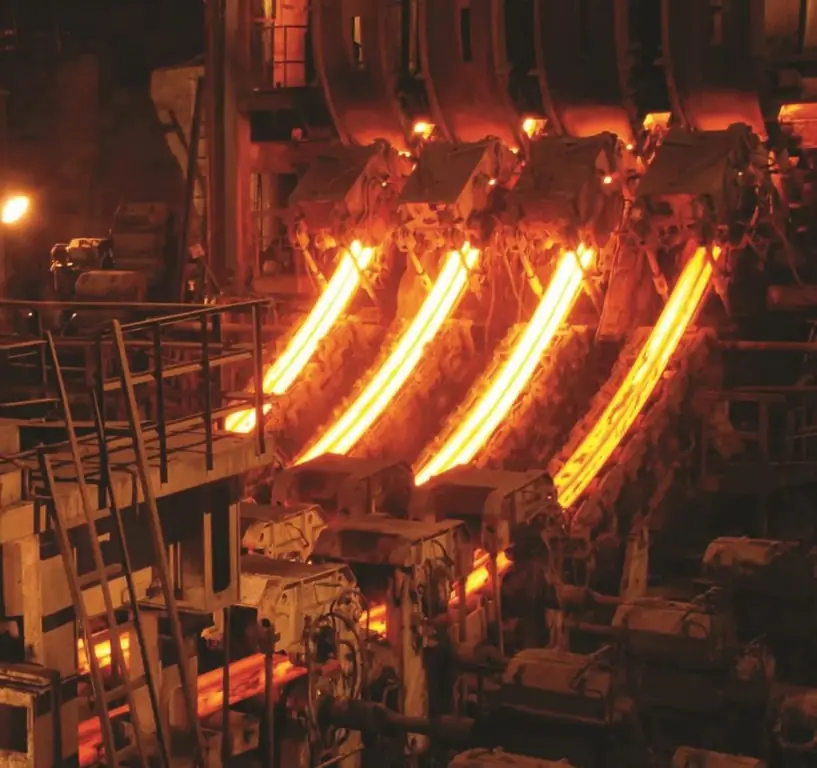

Continuous casting of steel: principle of operation, necessary equipment, advantages and disadvantages of the method

Today, a huge number of various things, parts, etc. are made of steel. Naturally, this requires a large amount of source material. Therefore, the plants have long been using the method of continuous casting of steel, characterized by the most important feature - high productivity

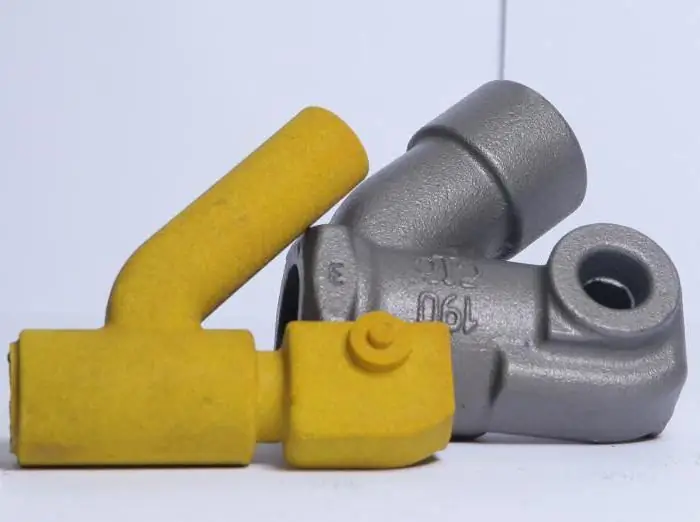

Casting mold: features, technology, types

One of the most important processes in the industry is the process of casting various parts, raw materials and other things. However, in order to successfully produce the desired thing, it is necessary to make a mold for it, which largely determines the final result

Shell mold casting: basic mold making operations

Currently, the industry is seriously developed and many different methods are used in casting. One such method is shell casting

Vacuum membrane press. Equipment for the manufacture of furniture blanks

Vacuum-membrane press is equipment designed for applying PVC or veneer decorative film to the facades of cabinets and sets. Equipment of this type is characterized by a not too complicated design and ease of use

Gating systems: types, device. Casting mold

Gating systems: principle of operation, description, features, device, operation. Mold for casting: purpose, characteristics, photo