2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:45

Materials science is, of course, a very extensive and time-consuming branch of science. Studying it is quite difficult and, frankly, quite tedious. Everything from the fact that you need to remember a large amount of information, in which it is easy to get confused due to its monotony. However, knowing what specific characteristics this or that material has, we understand what to do with it and how to use it in everyday life or at work. This article is just an occasion to highlight for readers a relatively small part of the information on the characteristics of a very common Kh12F1 grade alloy, its application features, composition, analogues and several more aspects, which are discussed below.

Deciphering steel Kh12F1

So, let's start with the simplest. Steel grade X12F1, according to all currently available GOSTs, is designated as tool stamp steel.

Having a general idea of the Russian steel naming system, given the information already available, we can safely draw several conclusions:

- Tool steel, which means it incorporates a certain setalloying elements.

- The letter “X” at the beginning of the steel grade, as well as the number 12 after it, indicate a chromium content of 12%.

- The letter designation “F” corresponds to the alloying element vanadium, and the unit is the content in the region of 1%.

Application

Based on the designation, it is clear that steel is used for stampings, or rather, for their manufacture. Accordingly, it is mainly used to make press dies, rolling rollers, often with a complex texture, dies for cold pressing and a number of parts associated with metalworking by extrusion under high pressure.

Composition

One of the most important aspects of metallurgy is the ligature composition of the alloy. It is from the presence, absence and percentage of all chemical elements that steel acquires certain properties required from it on duty in the future service.

For Kh12F1 steel, the following composition of alloying additives is provided, mentioned for ease of perception in averaged values:

- First in line is carbon (1.35%) - the most important element that turns iron into steel, giving it rigidity and hardness.

- Next, chromium (11.75%) is noted - this chemical element significantly increases the life of the part, preventing it from oxidizing under the influence of the external environment, creating a protective film of oxides. However, in addition to this, at a high content, it increases the strength of steel, its resistance to mediaelevated temperature, and, accordingly, to an unplanned vacation.

- Vanadium (0.8%) - favorably affects the structure of steel, increasing its strength characteristics.

- Silicon (0.25%) - as an alloying element, it serves to increase the resistance of steel to a high-temperature environment without loss of strength.

- Copper (0.3%) is a very common impurity in metallurgy. It does not assign any special negative effects to steel, but, on the contrary, slightly improves ductility.

- Manganese (0.27%) - even with a small content in the composition improves the hardenability of steel.

- Nickel (0.35%) - increases the strength characteristics of steel, albeit slightly, but in connection with other components, its role becomes more significant.

- Sulfur and phosphorus (0.03% each) are harmful impurities that have an extremely negative impact on the quality of steel. However, their content is so small that they are usually not counted.

Characteristics of Kh12F1 steel

Knowing the exact composition of steel, it is possible to determine its general characteristics with a certain degree of error.

- The first thing I would like to note is that the steel is high-carbon, which means it is exceptionally strong. This is not surprising, because its task is to bend, cut and emboss metal.

- Also it is chrome plated. This, firstly, protects the part from deformation during corrosion, and secondly, it makes the steel less sensitive to high temperatures.

- It has a very complex internal structure. When stamping parts on the stamp itselfthere is a lot of pressure, and any microcrack or any other defect can lead to very disastrous consequences.

- Kh12F1 steel feels quite comfortable in environments with elevated temperatures. This is facilitated by a whole bunch of ligature elements and their compounds.

Analogues

As you might guess, the production processes in almost any enterprise that produces the same products are approximately the same. And this does not depend on the geographical location of production facilities. Accordingly, identical tools made from similar or similar materials are used for similar work. Die steel Kh12F1 was no exception. In various countries, a steel grade with a similar composition is produced just as successfully as in the post-Soviet space. Here are some of the most popular items:

- United States of America - D5;

- Japan - SKD11;

- England - BD2;

- Germany - Х155CrVMo12-1.

By remembering these steel grades, even when you are far from your native land, you can be sure that you can easily find a part for yourself from the material you need.

Second life

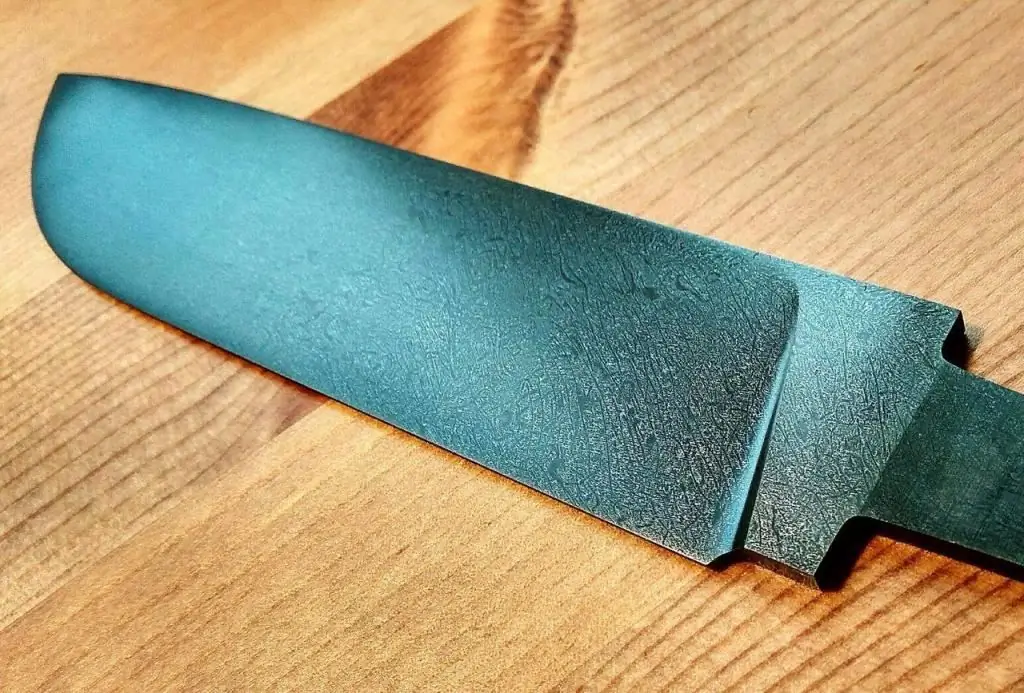

As it turned out, very flattering reviews about X12F1 steel can be heard from the lips of various craftsmen who make various household tools, be it chisels, knives, scrapers, and so on. The high carbon content in the composition makes it possible to achieve high hardness of the blade and cutting edge in particular, abundantthe amount of chromium prevents the appearance of corrosion, and the presence of an additional ligature in the composition, which has an extremely good effect on the overall structure of the material, makes knives made of Kh12F1 steel extremely reliable in operation, and therefore often simply irreplaceable.

Recommended:

CVG steel: composition, application and characteristics

Studying metallurgy and all its subtleties, you involuntarily begin to experience an irresistible desire to get as much useful information as possible and spend as little time and effort as possible on it. In such a case, this article exists. It contains all the most important information related to CVG steel: deciphering the marking, studying the composition, the use of this alloy, as well as a brief excursion into substitute steels and foreign analogues. Everything you need in one place for everyone's convenience

Food stainless steel: GOST. How to identify food grade stainless steel? What is the difference between food stainless steel and technical stainless steel?

The article talks about grades of food grade stainless steel. Read how to distinguish food stainless steel from technical

Steel grade R6M5: characteristics and application

Before starting to create a knife, the master needs to clearly know all the features of the steel from which the final product will be made in the future. Each individual steel, with the exception of analogues, which will be discussed below, is unique in its composition, which means that its processing should be approached wisely. So, the focus of our attention is R6M5 steel, the characteristics and application of which we will describe in detail below

Steel 20X13: characteristics, application and analogues

This article is a brief description of all the features of steel 20X13: characteristics, application, properties, substitutes and foreign analogues. This article will be useful to those who want to get acquainted with the most important information on this topic in a short time without wasting time

440 steel - stainless steel. Steel 440: characteristics

Many people know 440 steel. It has established itself as a reliable, anti-corrosion, time-tested hard material, which is most often used for the manufacture of knives for various purposes. What is the secret of this alloy? What are its chemical, physical characteristics and applications?