2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

Before starting to create a knife, the master needs to clearly know all the features of the steel from which the final product will be made in the future. Each individual steel, with the exception of analogues, which will be discussed below, is unique in its composition, which means that its processing should be approached wisely. So, the focus of our attention is R6M5 steel, the characteristics and application of which we will describe in detail below.

Chemical composition of R6M5 steel

Who is familiar with the Soviet system of steel marking, immediately recognized the main purpose of this brand. However, for those who have only recently begun to study this topic, it should be mentioned:

R6M5 steel is high-speed tool steel

As the name suggests, R6M5 steel has more than acceptable characteristics for the manufacture of cutting objects. It is easy to guess that all steels of this typeThe Soviet system was designated by the initial letter “R”, from the English Rapid, that is, “fast”. The rest of the marking is the name of the main alloying additives. In this case, the number “6” indicates the amount of tungsten (W) in the composition, and the abbreviation “M5” tells us about the presence of molybdenum (Mo) in the composition in the amount of five percent of the total weight. However, the main ligature composition looks like this:

- 0.9% carbon (C);

- 6% tungsten (W);

- 5% molybdenum (Mo);

- 4% chromium (Cr);

- 2% vanadium (V).

In addition to this set, there are a number of minor additives, but they can be safely ignored, because in R6M5 steel the characteristics are set precisely by the above alloying elements.

And the promised counterparts:

- In the United States market, the closest analogue is called T11302 or M2.

- In the Land of the Rising Sun, the analogue is called SKH51.

- In Europe you can find analogues called Hs6-5-2 or 1.3339.

In progress

Next, the characteristics of R6M5 in the work will be considered, we will list the main steel processing processes and clear temperature limits. So:

- Annealing. The limiting annealing temperature is 880 °C with a decrease of 50 °C per hour. We reach the lower temperature limit of 650 ° C, after which we cool the workpiece in air.

- Forging. The temperature corridor at this stage starts at 1160 °С and ends at 860 °С.

- Hardening. At this stage, you will have to sweat, because the starting temperature here is 1200 ° C. Next, the workpiece is lowered intooil up to 200 °C, then back to air. As a result, we get a blade with a hardness of 62 units on the Rockwell scale. There is an opinion that this steel can also be hardened in water, but this is pure lies of lazy craftsmen.

- Vacation. You need to release the blade three times: for an hour each and at a temperature of 500 ° C. After that, its hardness will increase by about three units and will be 65 units. by Rockwell.

R6M5 steel: characteristics and applications for knives

The result of all your efforts is a blade with a strong cutting edge, but viscous enough to gradually dull without the appearance of small and not very chips. However, the blade, even with all the efforts, will turn out to be fragile, so we do not advise you to subject it to excessive loads.

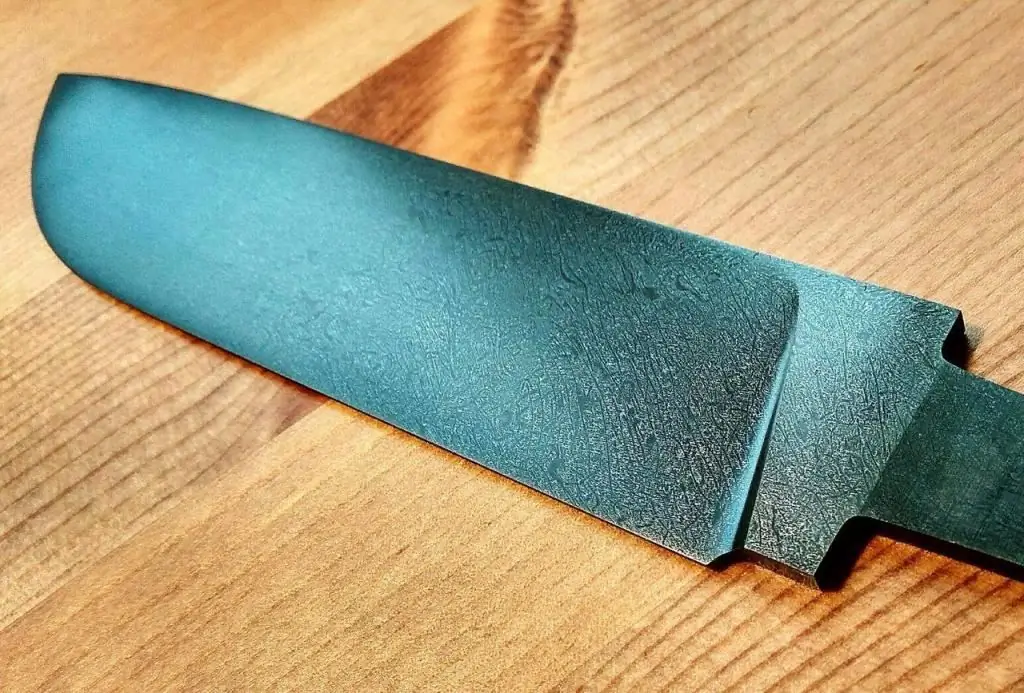

Without proper care, it slowly but rusts. When etched, it acquires an even black color. Grinding and polishing is good, but difficult - because of the high hardness.

Result

In the manufacture of you will require exceptional care, because steel is extremely capricious at the stage of heat treatment and is prone to decarburization when overheated. It is also worth being patient for the time of metalworking, because R6M5 steel has extreme strength characteristics. But if you follow all the subtleties, the final product will be extremely high quality and durable.

Recommended:

CVG steel: composition, application and characteristics

Studying metallurgy and all its subtleties, you involuntarily begin to experience an irresistible desire to get as much useful information as possible and spend as little time and effort as possible on it. In such a case, this article exists. It contains all the most important information related to CVG steel: deciphering the marking, studying the composition, the use of this alloy, as well as a brief excursion into substitute steels and foreign analogues. Everything you need in one place for everyone's convenience

Food stainless steel: GOST. How to identify food grade stainless steel? What is the difference between food stainless steel and technical stainless steel?

The article talks about grades of food grade stainless steel. Read how to distinguish food stainless steel from technical

Steel R6M5: characteristics, application

The alloy of an element of the eighth group of the periodic system of Mendeleev with atomic number 26 (iron) with carbon and some other elements is commonly called steel. It has high strength and hardness, devoid of plasticity and viscosity due to carbon. Alloying elements increase the positive characteristics of the alloy. However, steel is considered to be a metallic material that contains at least 45% iron

Sodium hypochlorite grade A: characteristics, application

Sodium hypochlorite is a chemical material used in various fields as a disinfectant. This compound can be used to disinfect all kinds of surfaces, materials, liquids, etc. There are several varieties of such a substance. Very often, for example, grade A sodium hypochlorite is used as a disinfectant

440 steel - stainless steel. Steel 440: characteristics

Many people know 440 steel. It has established itself as a reliable, anti-corrosion, time-tested hard material, which is most often used for the manufacture of knives for various purposes. What is the secret of this alloy? What are its chemical, physical characteristics and applications?