2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:45

Niobium is a chemical element with 41 serial numbers. It was first discovered at the beginning of the 19th century, but its recognition was delayed by 150 years. Only in 1950, by the decision of the International Union of Applied and Theoretical Chemistry, the atom was allocated its own cell in the periodic system of Mendeleev.

In order to use the useful qualities of the element in the industry, a niobium strip is made from it. By itself, it has nothing unique. Its full potential is revealed when creating alloys, solutions and other compositions.

Niobium mining

Enrichment of niobium ores is a very complex and costly process. This is because its content in one ton of rock does not exceed 24 grams. In addition, the element is very difficult to distinguish from tantalum due to similar chemical properties.

Under natural conditions, it occurs only in scattered form - in igneous rocks and crystals, as well as in the composition of some minerals - pyrochlore, loparite, columbite-tantalite. This element of the periodic table is mined mainly frompresented compounds. The production of niobium consists of three stages:

- Explore rock with a high content of niobium.

- Separation of niobium from tantalum, obtaining their pure compounds.

- Restoration and purification of metal and its alloys from impurities.

The production cycle is based on high-temperature thermal processes using aluminum, sodium or carbon. Directly niobium strips are obtained by pressing the powder, sintering powder "cubes" in a vacuum, as well as electric beam arc melting.

Useful properties

Due to its outstanding characteristics, niobium is used in many industries. To facilitate the process of introducing the element into the formula of the base composition, various rolled products are manufactured, including a niobium strip. The main active ingredient in this case is niobium carbide, which has a beneficial effect on the mechanical properties of materials.

It takes only 200 grams of niobium to alloy one ton of steel. The resulting alloy is distinguished by high hardness and ductility, low brittleness, and better corrosion resistance. The element is also used for protective non-ferrous metals, in particular aluminum, from alkalis and acids.

Use of niobium

Niobium strip is most often used as an alloying additive in the creation of alloys from both non-ferrous and ferrous metals. The main areas of application of niobium are rocket science, radio and electronic engineering, chemicalapparatus engineering, aviation and space engineering.

The use of metallic, or pure, niobium is due to a number of its useful properties. Among them, refractoriness, corrosion resistance, the ability to increase the heat resistance of materials and their conductive ability stand out.

The unique quality that the niobium strip has is almost zero interaction with uranium isotopes at temperatures up to 1100 degrees Celsius. Moreover, the atom has low artificial radioactivity. All this allows it to be used to protect nuclear reactors, as well as containers for storing spent radioactive fuel.

Niobium products

Metal niobium products are mainly used to meet the needs of the nuclear industry. Here, shells for uranium and plutonium fuel elements, containers for storing liquid metals, radioactive waste are obtained from it.

Niobium products are used to create heavy-duty computing equipment. With its help, the resistance of conductors is reduced, thereby obtaining cryotrons - superhigh-conductivity computer elements. In Austria, an alloy of silver and niobium was used to mint collectible coins.

Recommended:

Ceramic material: properties, production technology, application

The first pottery appeared long before people learned how to smelt metal. Ancient pots and jugs that archaeologists find to this day are proof of this. It is worth noting that the ceramic material has unique properties that make it simply indispensable in some areas

Niobium foil: production and application

Not all elements of the periodic table received their own cells immediately after opening. For example, niobium. It was discovered in 1800, but recognized after 150 years. In the industry, niobium foil has occupied a certain niche and strengthened itself in it, since it has useful characteristics. Its potential is revealed when used as a raw material for the creation of alloys, solutions and chemical mixtures

Alcohol-rosin flux: properties, application, self-production

Today, soldering is not the most common connection method, but it is still used quite often. Flux is always used for this operation. It can be not only purely rosin, but also a solution based on it. It's about alcohol-rosin flux

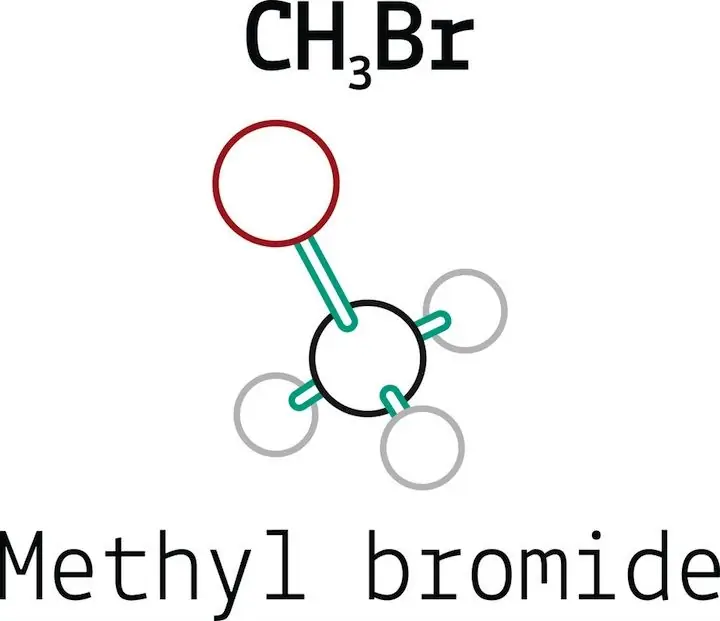

Methyl bromide: properties, production, purpose and application

Methyl bromide is a fumigant used against a wide range of pests including spiders, mites, fungi, plants, insects and rodents. Introduced as a pesticide in 1932. Methyl bromide fumigation is used to fumigate agricultural commodities, grain silos, mills, ships, clothing, furniture, and greenhouses

Use of niobium. Niobium production in Russia

At present, with the development of industry, there is a need for more and more quality materials. One of these is niobium. The use of this substance is not very widespread, but only because the price for it is quite high. However, this substance has excellent characteristics