2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:29

The first pottery appeared long before people learned how to smelt metal. Ancient pots and jugs that archaeologists find to this day are proof of this. It is worth noting that the ceramic material has unique properties that make it simply indispensable in some areas. Let's take a look at the features of ceramics with you, talk about its production and characteristics.

General information

Get ceramic products by sintering clay and mixtures with organic additives. Sometimes oxides of inorganic compounds are used. The first such products appeared 5,000 years ago. During this time, the production technology has improved significantly, and today high-strength ceramic products are available to us. They are used in construction for facade cladding, floors, walls, etc.

There are pottery with a dense and porous shard. The key difference between the two is that the dense shard is waterproof. These are porcelain products, floor tiles, etc. Porousshard - tiles, ceramic stone, drainage pipes and more.

History of occurrence

The word "ceramics" in Greek means "clay". Naturally, some kind of mixture was used to make any product. The necessary materials were added to it, depending on what needed to be obtained in the end. At first, by hand, and somewhat later on a special machine, a special shape was given to a clay product. Subsequently, ceramic products are fired in kilns at high temperatures.

Many countries used their own production technologies. This applies to pottery, painting and glazing. Egypt is considered the first state that has achieved significant development of this industry. It was the production of ceramics there that was established in the first place. Products were made of rough and poorly mixed clay, but later the technology improved. Today, yellow clay bricks are found that were allegedly used in the construction of the pyramids of Memphis.

The advent of porcelain

Jade has been used in China for a long time. It was beautiful, but rather fragile and difficult to handle. After many years of searching, a solution was found. Porcelain is easier to manufacture. However, even here there were nuances. For example, mica and tsvaoka, which were found in "porcelain stones", were ground into a fine powder and stored for more than 10 years. This was done in order to make the material as flexible as possible. FirstPorcelain products in China were tall and elongated vessels. They had a polished surface and a blue or dark green color. The latter were valued the most.

Today it is believed that China is the state where porcelain was most widely distributed. This is true, although it was popular in Europe, but it appeared there later, and its production developed longer.

Main types of pottery

Currently, clay products have a wide classification. So, pottery items can be divided into two main groups:

- unglazed ceramics (terracotta and pottery);

- glazed (majolica, faience, porcelain, fireclay).

Terracotta - from Italian "baked earth". Products are made of colored clay and have a porous structure. Terracotta is used to make vases, dishes, as well as toys and tiles.

Pottery pottery is more difficult to process. In order to make it waterproof, polishing is necessary. Further, the product is subjected to staining. To do this, it is left in a hot oven in smoke until it cools completely. Today, many types of ceramics, in particular pottery, are extremely popular. It is used in everyday life for storing milk, bulk materials or as a decor.

As for the second type - glazed ceramics, porcelain and earthenware are the most popular here. The first is more expensive and labor-intensive in production, the second is practical and cheap. They differ from each other in that porcelain products containless clay and more special additives. In addition, porcelain is translucent in the light, unlike earthenware.

About refractories

Products made from clay mixtures are refractory. Depending on the purpose, they can withstand temperatures from 1,300 to 2,000 degrees Celsius, and even higher. A special kiln for firing ceramics is used. Refractory materials are most widely used in the metallurgical process. There they are used to design blast furnaces and units.

It is quite logical to say that with increasing temperature, the strength of the refractory is not lost, but, on the contrary, increases. This is achieved due to the presence of refractory oxides, silicates and borides in the composition. They are used almost everywhere where high-temperature processes take place. Very often they are found molded, that is, in the form of a specific product, for example, a brick. Rarely, it is necessary to use unshaped refractories in powder form.

Ceramics in construction

The advantage of ceramic materials is that their stocks are practically unlimited. Along with the ease of production and high durability of such a product, today it is indispensable in the construction industry. If we take wall materials, then the clay brick occupies the leading position here.

The same applies to ceramic tiles, which, despite the appearance of polymers, is not losing ground. It is still used for equipping rooms with high humidity and temperature. Among the facing materialsexpanded clay takes the first place.

Over the past few years, the production of hollow ceramic blocks and bricks has increased by 4%. Their production requires minimal changes in brick plants and factories, while the costs pay off in the first year of sales. Abroad, hollow ceramics has long taken a leading position and is sold much better than ordinary bricks.

Special ceramic materials

Such products include sanitary and sewer pipes. The first are divided into three large groups:

- from hard faience (porous shard);

- sanitary china (sintered shard);

- semi-porcelain (half-baked shard).

The main requirements for sanitary ware are resistance to mechanical damage, heat resistance. The recipe must be followed in strict order, the same applies to technology. Only a professional ceramic kiln and high quality raw materials are used. Sanitary products include sinks, toilet bowls, bathtubs, radiators, etc. A sure way to check the quality of a product is to lightly tap on the case. The sound should be clear and free of rattles. This indicates firing at the correct temperature and no cracks.

As for the sewer pipes, they must have a dense sintered shard. Ceramic pipes are produced with a diameter of 150-600 mm. Usually glazed both inside and out. Such products are characterizedhigh resistance to aggressive environment and stray electric current. They are moderately priced, making them more affordable.

Physical and chemical properties of ceramics

As noted above, all products can be divided into two broad groups: dense and porous. Dense have a water absorption coefficient of less than 5%, porous - 5% or more. The last group includes the following products: clay bricks (porous and hollow), hollow wall stones, facing tiles, roof tiles. Dense ceramic products - road bricks and floor tiles. Both porous and dense ceramics are found in the sanitary industry.

Speaking of physical and chemical properties, it is impossible not to note the key disadvantage of ceramics. It consists in increased fragility compared to other materials. Nevertheless, high availability and versatility make this material one of the most popular in many industries and even in everyday life. Modern technologies make it possible to obtain a smooth surface immediately after firing. If you want to achieve a certain color, then add oxides of iron or cob alt.

Features of the microstructure

When heated, ceramics gradually become liquid. It is distinguished by a large number of simple and complex compounds. On cooling, crystallization occurs. It manifests itself in the precipitation of pure crystals, which increase in size. When the mass hardens, it forms in the structuremicroconglomerate. In it, mullite grains are cemented by a hardened mass. It is worth paying your attention that the oxygen atoms form a kind of matrix. It contains small metal atoms that are replaced in the voids between them. Consequently, ionic bonds predominate in the microstructure and somewhat less covalent bonds. Chemical stability and stability are achieved through the presence of strong and durable chemical compounds.

As noted above, the use of ceramic materials is limited. This is due to the fact that the crystals are imperfect. Crystal lattices have many defects: atomic-sized pores, deformations, etc. All this significantly impairs strength. However, there are some nuances here. For example, if the technology is observed during the manufacture of a particular type of ceramic, it is quite possible to achieve good results in strength. To do this, it is extremely important to observe the temperature regime and the duration of the firing of the product.

Characteristics and properties of clay

Clay is a sedimentary rock that, regardless of composition and structure, when mixed with water, forms a plastic material. After firing - a stone-like body. Usually the mixture is dense, mostly consists of aluminosilicates. Quite often, rocks such as quartz, feldspar, sulfur pyrites, as well as hydroxides and carbonates of calcium, magnesium and titanium compounds are also found in clays.

Kaolins are the purest clays known today. Almost entirely composed of kaolinite. After roasting getWhite color. The plasticity required for processing is achieved due to the presence of fine grains of clay matter (0.005 mm) in the structure. Naturally, the more such a substance in the composition, the higher the plasticity, and vice versa.

The main ceramic properties of clays include:

- plasticity - deformation without breaking the integrity;

- connectivity;

- air and fire shrinkage;

- fire resistance.

Today, various thinning and enriching additives are used, which allow changing the properties of the material in one direction or another. This leads to the fact that ceramic products become even more in demand and affordable.

Technological scheme of production

Characteristics of ceramic materials indicates the possibility of using clays in various industries. This led to the fact that there was a great demand, and consequently, the supply increased. Production plants in most cases work according to the same pattern:

- extraction of raw materials;

- preparation;

- shaping and drying;

- roasting and product release.

To minimize costs, factories are usually built in the immediate vicinity of the clay deposit. Mining is carried out in an open way, that is, with an excavator. The next step is to prepare the mass. Raw materials are enriched, crushed and mixed until a homogeneous mass. The formation of the future ceramic product is carried out by wet and dry methods. In the first case, the mass is moistened up to 25%, and in the second - no more than 12%.

In the past, natural drying was often used. However, the result depended largely on the weather. Therefore, in rain or cold, the plant stands still. Therefore, special dryers (gas) are used. The most critical step is firing. It is extremely important to comply with the technology, which is quite complex. Much also depends on the cooling of the ceramics. A sharp temperature drop is not allowed, which can lead to a curvature of the plane. Only then can you sell ceramic materials. The production technology, as you can see, is not simple, it consists of several stages. Each of them must be followed. If this does not happen, then on the shelves of the store we can meet marriage.

A little about the disadvantages of ceramics

As already mentioned, the composition of ceramic materials is not ideal. In particular, this affects the strength of the clay product. Any mechanical damage can manifest itself as a chip, crack, etc. This is the key disadvantage. But there are other factors that hinder the widespread dissemination of the material we are considering. One of them is high cost. For example, ceramic tiles for the roof of a country house are an excellent solution from an aesthetic point of view, but such a pleasure will be very expensive.

At the same time, its appearance will last no more than 5 years with proper care. In the future, fading occurs, the appearance of moss on the surface, etc. Along with this, fragility and brittleness lead to the fact that anymechanical damage can cause the roof to leak, and few people will like it. Of course, modern ceramic material looks very impressive, which is achieved due to the wide texture of colors and high quality workmanship. But it is still expensive, which often makes one think about the appropriateness of such a choice.

Summarize

We have considered the basic properties of ceramic materials. Based on all of the above, we can conclude that such products have some uniqueness. It lies in the fact that in the absence of mechanical damage, they will last a very, very long time. In addition, ceramic material for casting liquid metal in factories is also indispensable, because it can withstand high temperatures.

As for everyday life, then ceramics come in very handy. Special dishes for cooking in the oven, although they have changed their appearance over the years, are still made from this material. Porcelain, despite its high cost, has an elegant look and is simply pleasing to the eye. This also applies to earthenware, which, if properly executed, is difficult to distinguish from porcelain.

In any case, ceramic material must be used. This is primarily due to the large reserves of natural clay. There is really a lot of it, and every year more and more new quarries for the extraction of this natural resource are being developed. The second important factor is environmental friendliness. Previously, people did not have the opportunityuse any harmful additives to improve the strength characteristics of the product. Today the situation has changed, albeit not too critically. Ceramic tiles, unlike synthetic materials, are not harmful to he alth. This also applies to ceramic dishes, which, compared to plastic, especially if the latter is heated, do no harm at all.

Recommended:

Alcohol-rosin flux: properties, application, self-production

Today, soldering is not the most common connection method, but it is still used quite often. Flux is always used for this operation. It can be not only purely rosin, but also a solution based on it. It's about alcohol-rosin flux

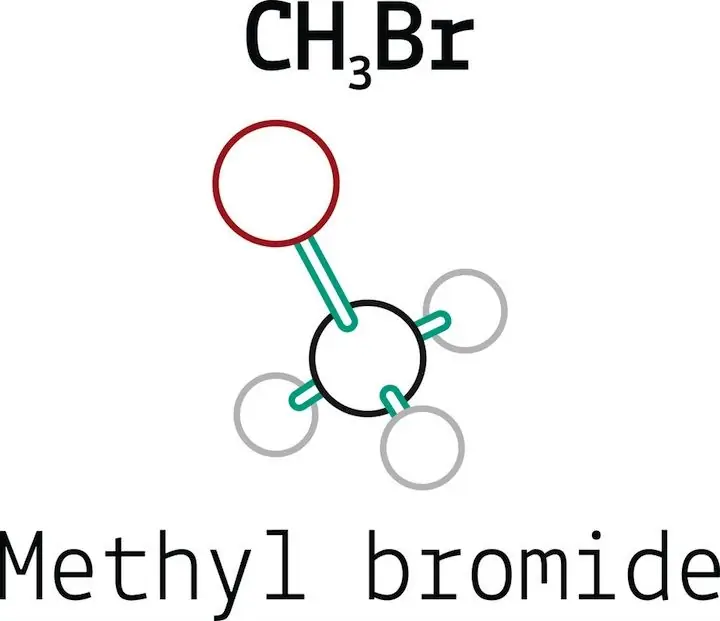

Methyl bromide: properties, production, purpose and application

Methyl bromide is a fumigant used against a wide range of pests including spiders, mites, fungi, plants, insects and rodents. Introduced as a pesticide in 1932. Methyl bromide fumigation is used to fumigate agricultural commodities, grain silos, mills, ships, clothing, furniture, and greenhouses

Production of plywood: technology, main stages of the process and areas of application of the material

Plywood is one of the cheapest and most practical building materials. Despite the multi-layer structure, it is easy to install and can be processed at home without special equipment. Standard production of plywood involves the use of wood lamellas, with proper processing of which you can get a finishing material that is resistant to a variety of threats

Ferrous sulfate: physical and chemical properties, production, application

Ferrous sulfate is a chemical compound that is extremely common in nature and widely used in various fields of economic activity. There are divalent and trivalent modifications of this substance. The first variety, also called ferrous sulfate, is an inorganic binary non-volatile compound having the formula FeSO4

Modern durable and high quality material G10: description, properties and application

People have been using knives as household tools for a very long time. With the passage of time and the improvement of technology, more and more new substances were used to create this tool. To date, the G10 material has become a new word in the creation of these things