2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:25

There is currently no single universal method. The choice of a suitable wastewater disinfection method depends on the results of preliminary laboratory tests. Various methods are used in private, industrial and public drains.

Required degree of cleaning

In some cases, it is enough to filter the water to the technical level. Certain industries make it possible to simplify cleaning mechanisms. This usually happens in factories where the level of biological contamination is not critical. The initial filtration procedures, regardless of the object and the final purpose of water, are generally the same. Differences begin only in the final stage, when the required degree of purification is determined.

For example, very different requirements today are imposed on the disinfection of wastewater in the transformation of domestic wastewater and liquid from natural sources into clean drinking water. A number of obligatory sanitary rules and norms are already observed here. In general, the procedure becomes much more complicated and expensive. For this reason, every city or industrial cleaningThe station has its own laboratory, where specialists regularly monitor the quality of water filtration.

Actual methods

The purpose of these procedures is to reduce the risk of mass infectious diseases, as well as to eliminate the prerequisites for a negative impact on people's he alth. All methods of wastewater disinfection can be divided into four large groups.

- Physical cleaning. Includes exposure to water by electromagnetic radiation or electricity.

- Chemical cleaning. The main work is done through the introduction of various elements and connections.

- Physico-chemical cleaning. It implies the use of joint filtering methods.

- Biological treatment. Presented by methods of natural and artificial biocenosis.

As practice shows, the successive use of various cleaning methods demonstrates the greatest efficiency. If there is a need, then not only the water itself is disinfected, but also objects that came into direct contact with it, for example, surgical equipment, materials and apparatus in the food and biochemical industries. For technical needs, more severe cleaning methods are allowed.

Physical radiation disinfection

This group of options is considered quite simple and inexpensive to operate. The most commonly used are infrared and ionizing devices, as well as UV emitters. Disinfection of waste water with the help of the last ofThese types of equipment directly affect the DNA of microorganisms living in the liquid. Ultraviolet radiation is invisible to the human eye, however, the directed impact of waves with a wavelength of about 255 nm destroys the structure of all potentially dangerous bacteria and viruses.

One of the advantages of this method is the absence of negative residual effects. The low cost of equipment has led to the fact that this cleaning method has become one of the most popular in the industry. In some cases, UV disinfection of wastewater is combined with exposure to direct sunlight. Forced aeration in open-air ponds also helps to stop the reproduction of microorganisms and destroy them.

Infrared radiation is considered an indirect method, since it does not have a bactericidal effect. Liquid disinfection occurs due to the heating of physical objects and various accumulations of contaminants. Ionizing radiation is used only in situations where other options do not bring the desired result. The method is very expensive and difficult to use.

Features of wastewater disinfection with ultraviolet light

On the example of this method, you can consider the main installation device and the principle of use. In any version, there is a main unit - an ultraviolet camera or a disinfection chamber. Spectral electromagnetic waves of a certain frequency are generated inside the device. The chamber material is stainless steel, which is suitable foruse in the food industry. The ballasts themselves are located in the so-called electronic ballast cabinets. Automation is provided by the control system unit, and the unit for chemical washing of quartz covers is responsible for the smooth operation.

UV-installation for wastewater disinfection is suitable in almost all cases. However, a cloudy and heavily contaminated liquid can be cleaned somewhat worse. Such water is preliminarily prepared by other methods for subsequent treatment with ultraviolet radiation. Preliminary purification of the liquid from various mechanical inclusions, colored elements, fungi and cell walls makes it possible to increase the effectiveness of UV exposure. The environmental friendliness and safety of this processing method makes the liquid safe for human consumption, since the chemical and organoleptic characteristics remain unchanged.

Other physical cleaning methods

The options below are often combined with ultraviolet disinfection of wastewater. Among other physical cleaning methods, there are thermal effects, electric currents of high and ultrahigh frequencies, as well as ultrasound. The latter, for example, destroys the cell membranes of viruses and bacteria due to the high frequency of oscillations of the applied signal. Ultrasonic units work most effectively in combination with bactericidal agents added to water.

The following method is familiar to everyone at the household level: the thermal effect works by simply boiling water in a kettle. The complete death of all possible microorganisms occurs only after30-40 minutes of their presence in a boiling liquid. However, this method is too costly from a financial point of view. It takes a lot of energy to heat a large volume of water. Viruses, bacteria and their spores are able to successfully survive in boiling water for a short period of time.

The operation of installations of electric currents of high and ultra-high conductivity is in many ways similar to the previous method. Here, in the same way, pathogenic microorganisms are affected by heating the liquid. A wastewater disinfection plant of this type works like a conventional microwave oven. Ultra-high frequencies of electromagnetic field oscillations adversely affect the cellular structure of bacteria and viruses.

Chemical disinfection methods

There are a large number of elements that could destroy all organic matter that lives in a liquid with high efficiency. These include compounds of bromine and iodine, ozone and hydrogen peroxide. However, first of all, chemical disinfection of wastewater with chlorine comes to mind. This substance is used much more often than others. Chlorine gas, calcium or sodium hypochlorite, chlorine dioxide, bromine chloride, nirtan, chloramine, or bleach can be used. The main problem is that all of these substances are harmful to the human body. For this reason, additional disinfection of water after the application of chlorine is required.

You can also choose a gentle cleaning. The least harmful chlorine dioxide to humanscopes with the destruction of viruses and bacteria somewhat worse than analogues. If we talk about other elements and compounds for disinfecting drinking waste water, then we can only think of potassium permanganate, peracetic acid and similar chemical disinfectants. However, very weak bactericidal properties do not allow them to compete with chlorine and its derivatives. Sometimes certain metals are used, such as copper compounds and silver. They are able to release ions with bactericidal properties. The effectiveness of metal disinfection is quite low, and therefore the method is used only as an additional one.

Features of the use of iodine and bromine

The above bactericidal agents have been used for a long time in various medical applications. Nevertheless, the same iodine is poorly distributed in liquids on its own, which is why it is necessary to use organic compounds of this element in the purification and disinfection of wastewater. After the procedure, a very specific smell remains. For this reason, it is advisable to use iodine only for technical water, but not for drinking water. In large industrial volumes, such compounds are impractical to use due to their low distribution. Iodine is not resistant to sunlight and does not react with ammonia like chlorine does.

Bromine appears in a more favorable light. It is non-toxic, devoid of any characteristic odor and absolutely harmless to humans. With all its advantages, bromine requires the use of higher concentrations onthe same volume of liquid compared to iodine. High bactericidal performance is achieved due to the oxidation of the substance. Experts advise adding bromine or iodine in places where the same water is used many times. The high toxicity of by-products formed during the work still does not allow the use of these inexpensive elements everywhere.

Ozone disinfection

The method is actively used by enterprises in Europe and North America. Ozone compounds easily cope with a wide range of harmful viruses, bacteria, fungi and other pathogens. If we talk about complex systems for the disinfection of wastewater, then this method can be called the final or finishing. During ozonation, the liquid is already thoroughly filtered and processed using other physical and chemical purification methods. Among the negative aspects of the use of this method, one can note the poor solubility of this modification of oxygen in water, the risk of explosion of components and an increased level of released toxins. By-products that appear as a result of the cleaning procedure can harm humans and the environment.

The scheme of the device consists of six main blocks at once. Their full list is given below:

- Ozone generators. They are located directly in front of the primary treatment tank. Provide this element to other blocks.

- Compartments for primary and secondary ozonation.

- Block foraccumulations of the resulting sludge.

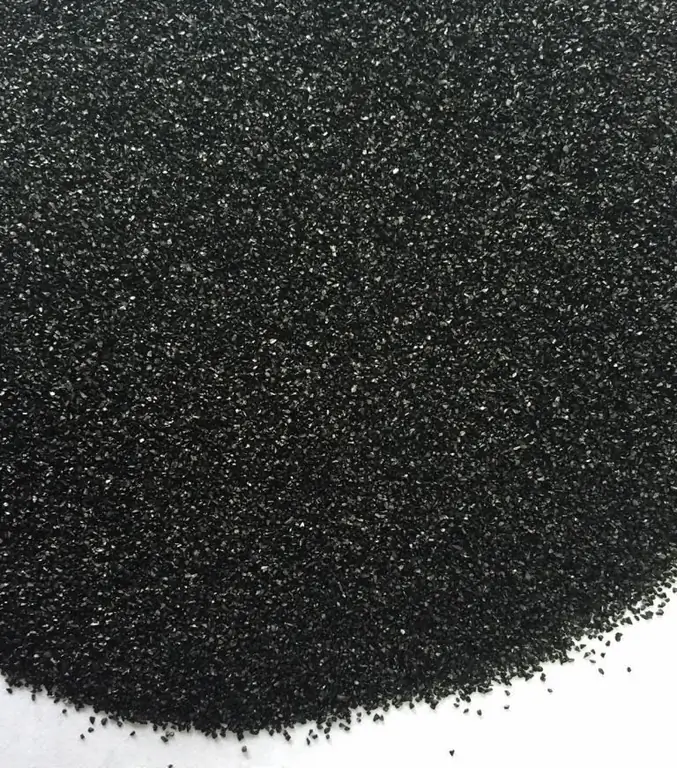

- Special sand filter. Usually located between the primary and secondary ozonation compartments.

- UV processing unit.

- Sorption filter.

Physico-chemical methods of disinfection

In general, we can say that the quality level of various effects on the liquid is often raised by adding any substances and elements that have the desired bactericidal properties. Sometimes a direct electric current is also used in a special wastewater disinfection unit. The discharge is in excellent contact with viruses and bacteria in the liquid. The addition of certain chemical elements to water that is subjected to a constant electric current can cause the molecules to dissociate into ions. Experts attribute this cleaning method to physical and chemical ones.

Effective destruction of cells of pathogenic microorganisms is achieved through the participation of viruses and bacteria themselves in the process of cell dissociation. Often, hydrolysis and ionization of water are also carried out. The joint work of physical and chemical methods can also be traced when a liquid is heated. For the best level of wastewater disinfection, high temperatures are combined with the addition of certain ingredients, such as simple soap or lye. In more complex cases, special disinfectants, developed and tested in laboratories, are already being used.

Use of biocenoses for cleaning

Relatively new method. Disinfection of sewage sludge occurs due to anaerobic and aerobic bacteria, which feed on various biological contaminants. Special enzymes allow you to break down pathogenic microorganisms into simple chemical compounds. After that, the bacteria absorb all the organic matter found. Specialists artificially breed cultures of such “cleaners”, creating suitable conditions for their existence and reproduction. The habitat of bacteria is as close to natural as possible. Usually this method is used one of the last, when the water has already been sufficiently treated with ultraviolet radiation, chlorination, ozonation or ultrasound.

It is simply impossible to choose the best cleaning method that would be considered universal. For the most part, everything depends on the specific purpose of the disinfected water, as well as the results of chemical and bacteriological laboratory analysis. Basically, two or three most effective methods are selected. An interesting nuance lies in the fact that bacteria and viruses can eventually adapt and become immune to certain influences. That is why experts regularly take samples of wastewater and check it for a sufficient level of purification from pathogenic microorganisms.

Recommended:

Wastewater treatment from oil products: methods, methods and efficiency

At the moment, technologies and means, methods and units, thanks to which wastewater treatment from oil products is carried out, are among the most important means of ensuring environmental protection. In our country, for about five years now, legislatively fixed standards for the purification of liquids discharged by enterprises have been in force. Documentation on this issue establishes the quality and volume of water that can be produced by industrial facilities

Mechanical wastewater treatment: methods, features and scheme

Today, there are chemical-physical, mechanical and biological wastewater treatment. They differ in the nature of the processes underlying them, as well as technological parameters

Sewerage: cleaning, removing blockages. Wastewater treatment plant, biological wastewater treatment

The article is devoted to sewer systems and wastewater treatment facilities. Methods for cleaning sewer pipes, biological treatment plants and drainage systems are considered

Wastewater from industrial enterprises and methods for their regulation

Nature is a constantly evolving, wise, unique, self-healing organism. However, for such a recovery, a certain amount of time must pass. In the conditions of constant anthropogenic attack, nature does not have enough strength and resources to restore itself. Because of this, global environmental problems arise. One of these problems is the pollution of the World Ocean, and, as a result, the lack of clean drinking water in many regions of the world

Restoration of parts by welding and surfacing: methods and methods of restoration, features, technological process

Welding and surfacing technologies allow efficient restoration of metal parts, providing a high degree of reliability and durability of the product. This is confirmed by the practice of using these methods when performing repair operations in a variety of areas - from car repairs to the production of rolled metal. In the total amount of work on the repair of metal structures, the restoration of parts by welding and surfacing takes about 60-70%