2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:31

Today, there are chemical-physical, mechanical and biological wastewater treatment. They differ in the nature of the processes underlying them, as well as technological parameters. Let us further consider what mechanical methods of wastewater treatment exist.

General information

Waste water is used as a resource for industrial water supply. For industrial use, they must undergo special training. In the course of it, wastewater is cleaned from mechanical impurities. For this, special facilities are used. They differ in the type of structures and other parameters.

Types of structures

Used for filtering:

- Mechanical screens for wastewater treatment.

- Sand traps.

- Membrane elements.

- Primary settling tanks.

- Septics.

These structures are used in a certain sequence.

Specific scheme of mechanical wastewater treatment

At the first stage, the detention of largecontaminants of mineral and organic origin. Grids are used for this. Sieves are used for maximum removal of coarse elements. The maximum width of the holes in the grate is 16 mm. Components held by it are subjected to crushing. Then they are sent along with the sludge from the treatment plant for processing. Also, the isolated solid components can be taken out to the places of processing of industrial and household waste. After primary filtration, the effluents are passed through sand traps. Small particles of pollution are emitted here. This, in particular, is the breakage of glass, slag, sand, etc. Under the influence of gravity, they settle. Then the grease traps are involved. With the help of these facilities, hydrophobic substances are removed from the water surface by flotation. The sand released during the passage through sand traps is usually stockpiled and then used in road works. For deeper filtration, membrane elements are used. This technology has recently become quite widespread. Mechanical wastewater treatment by the membrane method ensures the return of raw materials to the production cycle.

Deposition method

Mechanical wastewater treatment by this method can be used, for example, to eliminate suspended particles. Filtering can be organized in two ways. The first involves the use of gravity pollution. Under its influence, in the process of settling, suspended particles settle to the bottom. Another way involvesuse of centrifugal force. Mechanical wastewater treatment by such methods makes it possible to eliminate insoluble elements, the size of which is more than a few hundred millimeters. In the process of preparing raw materials for reuse in production, settling tanks of a multistage type are often used. Partially filtered raw materials at one stage are fed to the next by pressure.

Flotation

Mechanical wastewater treatment by this method involves the transfer of pollutants to the surface with the help of air bubbles. As a result of flotation, foam formations appear. The polluting components which are contained in them are eliminated subsequently by means of scrapers. Air bubbles can be obtained mechanically. For this, nozzles or turbines, electroflotation, etc. are used.

Use of porous materials

This method is by far the most common. With the help of porous materials, the sediment of the mechanical treatment of oily wastewater can be eliminated. When filtering, meshes or materials of a special structure are used. This method is relevant for cases where it is necessary to use recycled water.

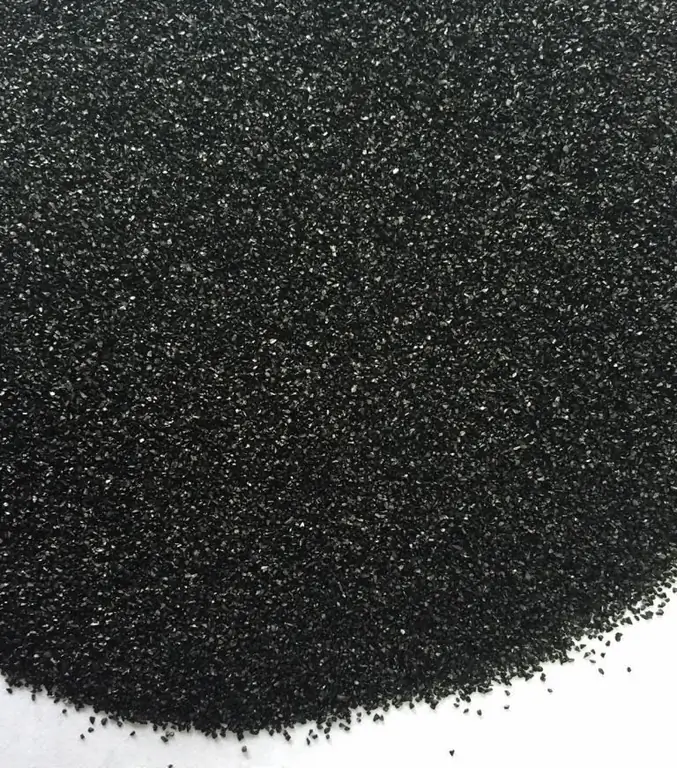

Features of sand traps

From the sewer network, wastewater flows to sieves and grates. Here they are filtering. Large items - kitchen waste, rags, paper, etc. - are held. Subsequently, they are removed and taken out for neutralization and disinfection. The filtered effluent is sent to sand traps. They are meantto protect sedimentation tanks from contamination with mineral particles. Sand trap designs may vary. It depends on the volume of incoming effluents. Sand traps can be vertical and horizontal, as well as slotted. The first two types are used in sewage treatment plants, and the last ones are used in canals. Vertical and horizontal sand traps are installed if the volume of incoming raw materials is more than 300 m3/day. Sand traps are made in two sections. This is necessary so that in the process of repairing one part, the second could function. In a horizontal structure, the process of sedimentation of mineral particles occurs when the liquid moves at a speed of 0.1 m/sec. In vertical sand traps, the release of impurities is carried out when the effluents rise up. The speed of fluid movement in this case is 0.05 m/sec.

Sumps

They are considered the main, and therefore the most common category of filtration facilities. Settling tanks may provide for horizontal or vertical movement of water. With a large volume of raw materials, continuous operation facilities are used. If the water flow per day is not more than 50 thousand m3, vertical sedimentation tanks are used. The operation of such structures is carried out as follows. Drains are brought along the central pipe to the lower part of the structure. The outgoing stream moves up to the collection and outlet trays. In the process of lifting, elements with a large specific gravity fall out of the water. Radial-type sedimentation tanks are also used for filtration.

Specificityprocessing

Industry uses primary and secondary clarifiers. Some are installed in front of biological filtration facilities, others, respectively, to clarify the effluents after them. Secondary clarifiers are also contact. If the terrain conditions allow directing effluents to water bodies, then a tank for disinfection should be provided in the filtration scheme. Suspensions isolated in the primary sump rot. The resulting mass is dried on special sites, and then used as agricultural fertilizer.

Aerators and biocoagulators

These types of facilities are designed for chemicalless treatment of impurities with excess sludge by blowing water with compressed air. Aerators are made in the form of rectangular tanks, in which partitions are installed, extending the path of movement of raw materials. These structures contribute to an increase in the level of clarification, the elimination of liquid fat. In aerators, mechanical treatment of oily wastewater is often carried out. These facilities also prepare raw materials for the next stage of filtration. Aeration is the process of blowing water for 10-30 minutes. Air is supplied through filters or openings in pipes. Biocoagulators are made in the form of a horizontal or vertical settling tank with an annular zone and a central compartment. It mixes and contacts excessively activated sludge with water. To reduce air flow in the corners of the central chamberinclude 4 triangular boxes. At the same time, horizontal tanks with filter plates are installed at a depth of 2.5-3 m. Water enters the central pipe through the inlet tray.

Action of structures

The raw material is introduced into the coagulator below the level of the filter plates. This prevents them from clogging with large particles. The sludge concentration is approximately 7 g/l. At the same time, its amount should be about 1% of the wastewater consumption. Compressed air is supplied to the filter plates. With its help, activated sludge is mixed with waste water and maintained in suspension. At the same time, the intensity of aeration should be kept within 1.8-2 m2/h. The liquid, treated with air, begins to move through the circulation boxes, which are installed at the corners of the central chamber. Its walls are longer than the containers. In the annular zone of the coagulator between the outer surfaces and the central chamber, a suspended silt layer is formed. Its level will depend on the flow of wastewater. This suspended layer promotes coagulation, equalization of the rate of rise of the raw materials and elimination of the direction of the vertical movement of the liquid.

Conclusion

Mechanical cleaning is the most important process in the work of an industrial enterprise. It is extremely necessary, because it allows you to prepare the liquid for the subsequent stages of filtration. In no case should mechanical cleaning be neglected. Otherwisesubsequent stages of filtration will be significantly more difficult. Moreover, the presence of large particles of contaminants can disrupt the operation of biological treatment facilities. This, in turn, will entail additional costs for the repair or even replacement of equipment. Filtration facilities must be selected in accordance with the specifics of the enterprise, the volume of effluents, as well as the need to reuse treated water.

Recommended:

Wastewater disinfection: methods and their features

Description of current wastewater treatment methods. Physical, chemical, physico-chemical and biological methods of disinfection. Combined application of various methods for the destruction of pathogenic microorganisms in wastewater

Wastewater treatment from oil products: methods, methods and efficiency

At the moment, technologies and means, methods and units, thanks to which wastewater treatment from oil products is carried out, are among the most important means of ensuring environmental protection. In our country, for about five years now, legislatively fixed standards for the purification of liquids discharged by enterprises have been in force. Documentation on this issue establishes the quality and volume of water that can be produced by industrial facilities

Sewerage: cleaning, removing blockages. Wastewater treatment plant, biological wastewater treatment

The article is devoted to sewer systems and wastewater treatment facilities. Methods for cleaning sewer pipes, biological treatment plants and drainage systems are considered

Wastewater treatment methods: the more the better

The higher the level of development of a civilization, the more waste it produces. Today, the most pressing questions of our time are: "Where to put sewerage? How to clean it? What is the treatment of sewage and wastewater?"

Restoration of parts by welding and surfacing: methods and methods of restoration, features, technological process

Welding and surfacing technologies allow efficient restoration of metal parts, providing a high degree of reliability and durability of the product. This is confirmed by the practice of using these methods when performing repair operations in a variety of areas - from car repairs to the production of rolled metal. In the total amount of work on the repair of metal structures, the restoration of parts by welding and surfacing takes about 60-70%