2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:47

Pumping of viscous liquids with a high concentration of technical impurities is provided by special pumping units. Such equipment is focused on operation in complexes of service stations, in production and in agriculture. As a rule, the oil transfer pump cannot be used for other types of liquids, but there are exceptions in the form of combined modifications.

Key features of oil pumps

One of the main characteristics is the voltage under which the pump operates. To begin with, it is worth noting that there are models that operate on 220 V, and there are industrial units that are connected to a 380 V outlet. There are also compact models designed for remote work that can be powered by battery packs with a voltage of about 24 V.

Depending on the requirements for the volume of fluid maintenance, the optimal power indicator is also selected. So, in the initial segment, you can find a pump for pumping oil from a barrel, the capacity of which is 5-10 liters per minute. These are units with a power of about 200-500 watts. If, according to calculations, it is necessary to serve 30-40l, then models with a power potential of 1000 watts should be preferred. At the same time, it should be remembered that a certain percentage of power will be spent on ensuring the device's operability in a viscous medium. That is, the harder the oil, the more power will be required from the pump to work with it.

Varieties of aggregates

Units are distinguished by features of functionality, purpose and technical device. The simplest option is a mechanical pump for pumping oil from a barrel. Manual crimping machine is also popular in the private sector and in small industries. Conversely, a group of professional specialized pumps is less common, which include diaphragm, sliding gate and pneumatic devices, additionally equipped with pressure gauges.

It is important to note the division of models by scope. Today, manufacturers specifically produce units for working with specific oil media in the chemical, oil, economic and other industries. As already noted, there is also a hybrid pump for pumping oil. The electric version of such a unit is the most convenient in terms of operation.

Reviews of Piusi Viscomat models

The Viscomat series from Piusi is represented by models with high performance and ease of operation. These units are successfully used both in production and in private households. A wide range of pumps with different technical characteristics allows you to choose the optimal version for work in specific conditions. Among the features that the Viscomat oil pump has, users note the presence of an efficient cooling system, well-organized heat transfer, as well as the presence of ergonomic controls. This is the case when responsible technology combines the advantages of professional machines and the advantages of models designed for domestic use.

Reviews of Jabsco models

Manufacturer Jabsco is known for good impeller pumps that can work effectively with liquids containing soft elements. As the practice of operating such a unit shows, it can stably perform its function, even if there are particles in the oil with a diameter of about 14 mm. The advantages of the equipment include a high-strength case, which protects against external influences. Stainless steel allows the pump to be used for pumping oil both under extreme production conditions and outdoors under the influence of precipitation. True, in frosty conditions, the operation of the unit becomes impossible. But there are practically no restrictions in the maintenance of oily fluids. Pump owners point to the presence of hygienic internal parts in the design that do not distort the chemical composition of the pumped medium.

Feedback on Flojet models

Electric pumps are especially appreciated in the Flojet linemembrane type, which are most often used to service used oil. Users testify that the diaphragm pump is able to function without damage even when running dry. It is important to note that the design provides for a sealed engine and a pump with two chambers, providing a self-priming function. Thanks to this arrangement, the Flojet oil transfer pump can be used to perform replacement, pumping and transfer of viscous liquids. Also, the advantages of this equipment, the owners include low noise levels. Thanks to good sound insulation, the unit can be operated even in conditions with increased requirements for the production process in terms of comfort.

Conclusion

Pumping equipment, unlike many other types of engineering and production equipment, is not so dramatically improved in terms of automation. The presence of electronic relays, of course, made its own adjustments to the operation processes, improved the quality. However, the traditional pump for pumping oil remains in demand. The manual version of this equipment is easy to use and maintain. It is these properties that are fundamentally important for small industrial enterprises, and even more so for private households. There is also an expansion of the segment of mechanical models of various types, which are developing in terms of strength and performance. Today it will not be difficult to find a reliable unit capable ofwork with a frequency of about 25 l / min. In other words, oil pump manufacturers are more likely to focus on the quality of the performance of basic pumping functions, while not forgetting about ergonomic nuances.

Recommended:

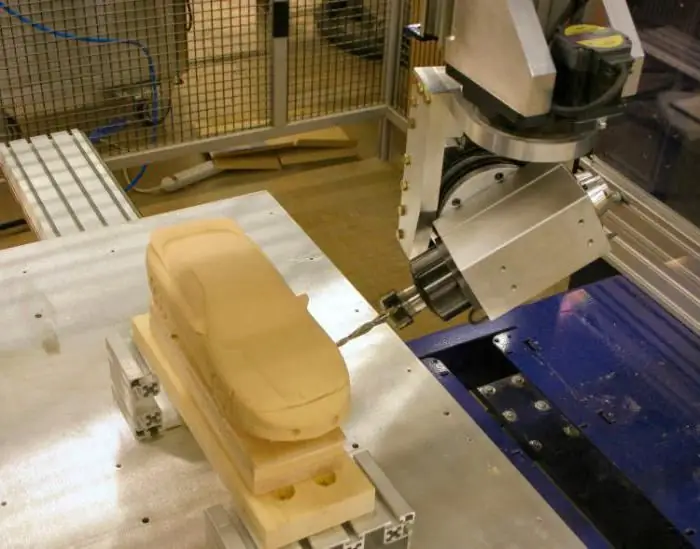

CNC small business machines - overview, types, specifications and reviews

CNC machines for small businesses: types, descriptions, features, photos. CNC machines for small businesses: overview, specifications, reviews

Copper radiators: overview, specifications, types, installation features and reviews

Copper radiators are appliances made of an amazing metal, it does not corrode, excludes the reproduction of microorganisms, and is also not afraid of chemical reactions

Tire changer for trucks: overview, specifications, types and reviews

The article is devoted to tire changers for trucks. The characteristics, varieties, reviews and nuances of choosing this equipment are considered

Industrial refrigerators: overview, description, types, specifications and reviews

Most people deal with equipment like refrigerators every day. But this technique is designed for the home. What devices are in production? After all, products are sold in large volumes. Industrial refrigerators are entire structures that are a refrigerating chamber for cooling or freezing food

The beneficial owner is Identification of the beneficial owner

"Beneficial owner" is a concept used to collect and store certain information about companies that interact with organizations listed in Art. 5 of Law No. 115-FZ