2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:26

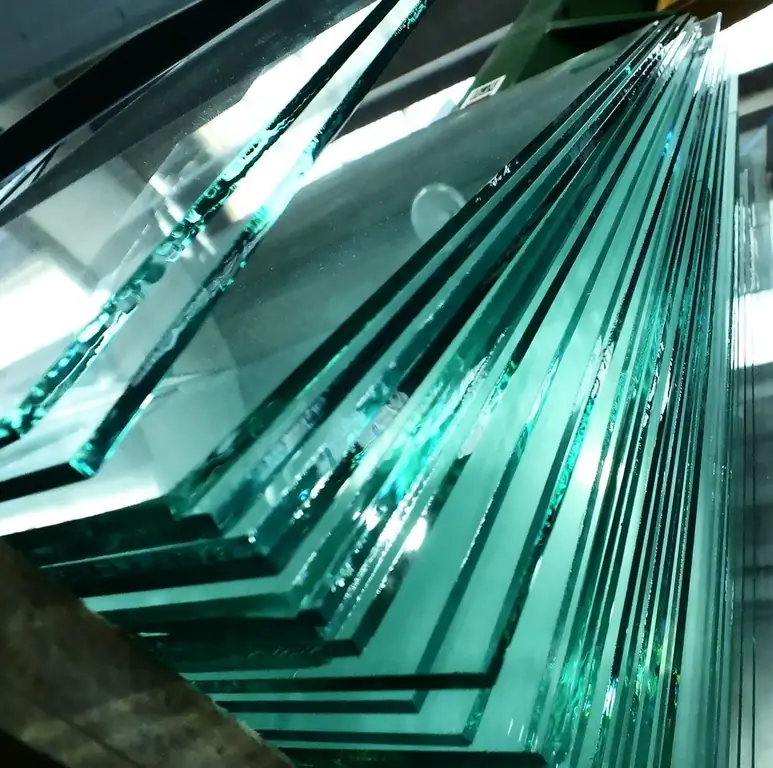

Among the numerous variations of interior decoration, sandblasting of a glass or mirror surface occupies a special place. This technology involves exposing the canvas to sand or other abrasive with a jet of compressed air released under high pressure. As a result, the surface changes and becomes matte, rough, velvety or painted with patterns. In the article, we will consider what sandblasting glass is.

Where does the method apply?

Most often, sandblasting a mirror or glass sheet is used in the following cases:

- When creating furniture. Even familiar objects after such processing become unique. The interior of the room becomes more presentable and better emphasizes the individuality of its owners. Sandblasted glass is used to decorate individual elements, interior doors andpartitions, windows. A mirror with a pattern or an ornament on the tabletop of dining furniture looks very elegant.

- In the design of office or retail space. Recently glass partitions at offices use special popularity. Status and good taste are demonstrated by engraving with the logo or symbols of the company. Entrance doors made of glass with original ornaments will emphasize the high level of the store, hotel or restaurant.

Sandblasting techniques

Today, there are seven main types of surface decoration using this method:

- Flat processing. A simple pattern is applied to certain areas of the canvas and sandblasted.

- Deep processing. Surface matting is performed more deeply. In this case, the minimum thickness of the web should be from 5 mm.

- Embossed sandblasted glass. For this technique, a canvas more than 6 mm thick is used, an ornament with relief and engraving is applied according to the template.

- Artistic sandblasting. It is characterized by intermittent matting of the surface. The drawing is applied using gradients and halftones on glass of any thickness. High-class masters of their craft perform artistic processing.

- Colored sandblasting. Involves the use of plain and fluorescent paints.

- Template processing. It is performed using special digital equipment.

- Double-sided sandblasting. Drawings on glass are made using a template. The image is applied simultaneously on both sides of the canvas.

Step-by-step glass sandblasting process

To obtain the desired result, a number of preparatory operations are performed before surface treatment. The level of quality of the applied drawing depends on how carefully they were carried out.

Sandblasting on glass (photo examples are presented in the article) requires the following steps:

- A selection of an ornament or pattern that will be applied to the canvas. Modern technical means have greatly expanded the possibilities of drawing a picture using this technique. The selected image is processed in a graphics editor, then a template is made on its basis. As a rule, metal, linoleum, a special film, paper or plastic are used for it. To create a relief pattern, the template is divided into parts that determine the depth of application.

- Making a template.

- Surface preparation, cleaning.

- Fixing the template on the canvas. If a simple pattern is applied, it will not be difficult to fix the stencil. A complex image needs a more careful approach. Each element of the pattern must be at a certain distance from the other part and securely fixed. After fixing, the template is smoothed with a roller for better adhesion to the surface and expulsion of air bubbles. Only after that they start sandblasting.

- Sandblasted.

- Coating the pattern with protectivelayer.

Advantages and disadvantages of the method

The indisputable advantages of the glass sandblasting method include:

- Multiple artistic possibilities. The equipment makes it possible to control the air supply pressure, thanks to which matting can be of different intensity, relief of different depths and toning.

- Machining large areas.

- The resulting image is not erased, sandblasted glass does not require special care, the layer does not leave marks when touched.

- Accessibility. Simple jobs don't require high-end equipment.

Among the disadvantages are:

- Limited scope. Processing is more suitable for flat surfaces.

- In the process, a huge amount of dust is released. Therefore, processing is carried out in a separate room, in work clothes and a dust mask.

- Professional equipment is expensive.

- It is important to monitor the quality of the abrasive used.

- Significant power consumption.

Tools and materials

For beginners, an air gun activated by a compressor is suitable. Its equipment may include a tank, hose or bag.

Equipment for professional glass processors involves the use of different technologies and abrasives:

- Standard sandblasting unit. Compressed air and abrasive are mixed in a container and, when turned on, are supplied tonozzle.

- Injector apparatus. More economical to use, air and abrasive are mixed right in front of the nozzle.

Sandblasting machines are used in the glass industry. Automated equipment allows you to process large surfaces in a short time.

When processing glass, abrasives of natural and artificial origin are applicable. Each of them is distinguished by its hardness index and the possibility of single or multiple use. Using different abrasive materials, you can get a coating with different depth of processing.

Most demanded abrasives:

- quartz sand, used in most cases;

- ceramic or glass powder;

- plastic abrasive;

- garnet sand, most often used as a cutting material;

- technical abrasive (cast iron, steel), environmentally friendly, but one of the most expensive;

- aluminum dioxide.

Technological features of the process

To get decor in various execution techniques, sandblasting masters carry out certain manipulations:

- Preparation of the full size stencil. It is carried out by a computer method with cutting out a template on special machines.

- Degreasing and cleaning the canvas with a special composition.

- The finished template is cut out and attached to the surface, eliminating the ingress of foreign particles and air.

- Nuances of the process - drawing,printed on the front side of the mirror, effectively reflected in it.

- Amalgam removal by sandblasting makes it possible to install LED lighting.

- The technique of matting paints allows you to depict luminous color paintings.

- The final step is to remove the stencil and cover the canvas with a protective water-repellent film that facilitates surface care and prevents contamination.

Process description, mirror processing

The effect that will be obtained with a simple sandblasting of glass (matte or mirror image) depends on the prepared template. The unprotected surface of the web is treated with an abrasive jet. This means that if the image is cut in the template, it will be matte. And if the template itself is a drawing, then the picture will remain transparent or mirrored, depending on the canvas. Sandblasting the glass of a cabinet or room divider is often done with these two techniques.

Along with the glass interior details, mirror elements are also processed in this way. The difference is that it can be done on both sides. Moreover, the pattern obtained by removing the amalgam layer from the inside will look voluminous. And the image printed on the front side will double. It looks very nice.

Sandblasting mirrors allows you to create matte patterns, ornaments and images on the surface, or, conversely, matte the surface, leaving a mirror pattern. The technique is used in the design of ceilings,decorative panels, interior partitions, furniture facades, interior solutions, mirrors directly.

Sandblast windshield

When searching for information, you can often hear this expression. It is worth noting that it has nothing to do with sandblasting the surface. Let's explain. The thing is that we sandblast the windshield on the slang of motorists called its minor damage received during operation. It can be microscopic dots, scratches, potholes, which are in the light of sunlight. Such defects are formed when particles of dust, stones get on the windshield when the car is moving. They can only be removed by polishing with special equipment.

And the car body can be sandblasted to remove corrosive formations, paint and primer (until a clean metal surface is obtained).

Recommended:

How to make glass? Glass production technology. glass products

Glass is familiar to everyone. But the process of making it is extremely exciting. Each stage is important and affects the quality of the final product. The basis is sand, soda, lime. The process is almost entirely automated. Surprisingly, glass can even be made at home

Glass processing: types and equipment

The article is devoted to glass processing. The varieties of processing methods, as well as the equipment that implements them, are considered

Sandblasting. Sandblasting and cleaning equipment

The article is devoted to the technology of sandblasting. The equipment for sandblasting and cleaning, as well as the features of its application are considered

Compressor for sandblasting. Sandblasting

The article is devoted to compressor units for sandblasting machines. The characteristics of this equipment, the nuances of use, etc. are considered

Meat: processing. Equipment for meat and poultry processing. Production, storage and processing of meat

Information of state statistics show that the volume of meat, milk and poultry consumed by the population has significantly decreased in recent years. This is caused not only by the pricing policy of manufacturers, but also by the banal shortage of these products, the required volumes of which simply do not have time to produce. But meat, the processing of which is an extremely profitable business, is very important for human he alth