2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:25

Examine yourself in a shop window, wash your face and look in the mirror in the morning, watch the outlandish mixing of coffee with milk through the transparent walls of the cup - habitual activities. And no one thinks about what way glass makes to become an integral attribute of the life of a modern person. It all starts with mixing unusual ingredients.

Glass production technology begins with the preparation and mixing of the components. The quality of glass products depends on the degree of preparation of the ingredients.

Raw materials

The most common silicate glass. The name comes from the name of the chemical element silicium oxide - SiO2. Quartz sand is a representative of this substance in nature.

Sodium sulfate, limestone, soda - that's what glass is made of. Some cullet is added to the composition.

Glass base sorting

Before glass is made, the sand is sieved and sorted. Raw materials of the worst quality are used for the production of window glass, the best - for the manufacture of dishes, jewelry,optical lenses and art products. The difference is in the size of the grains and the chemical composition: the finer the sand, the wider the scope of its application. If large grains of sand prevail, then such sand is the main raw material for window glass.

Initial sort

Sorted sand is transported to workshops for further processing. Quartz raw materials are placed in drums, the walls of which consist of the thinnest film. As the drums rotate, the sand is washed with clean water without detergents. The film is water permeable. The contents are ejected onto a conveyor which shakes the contents to screen out large pebbles.

Sorting from metals

The next step is fine filtration to clean the sand from metal inclusions. The impact of the latter will change the chemical composition of the glass. To do this, use spiral vertical troughs. Under the influence of centrifugal force, heavy metal particles are pressed against the inside of the chute, lighter sand along the outer edge is washed and goes on.

Drying

Wet raw materials are dried. The quartz sand is fed onto a round rotating conveyor. From below it is blown with hot air. The dried raw material is fed to the place of further processing.

Melting

The rest of the ingredients are added to the sand. Everything is poured into the melting furnace. At a temperature of 1600 degrees, everything is melted down and mixed with a special spatula, which is constantly cooled with cool water.

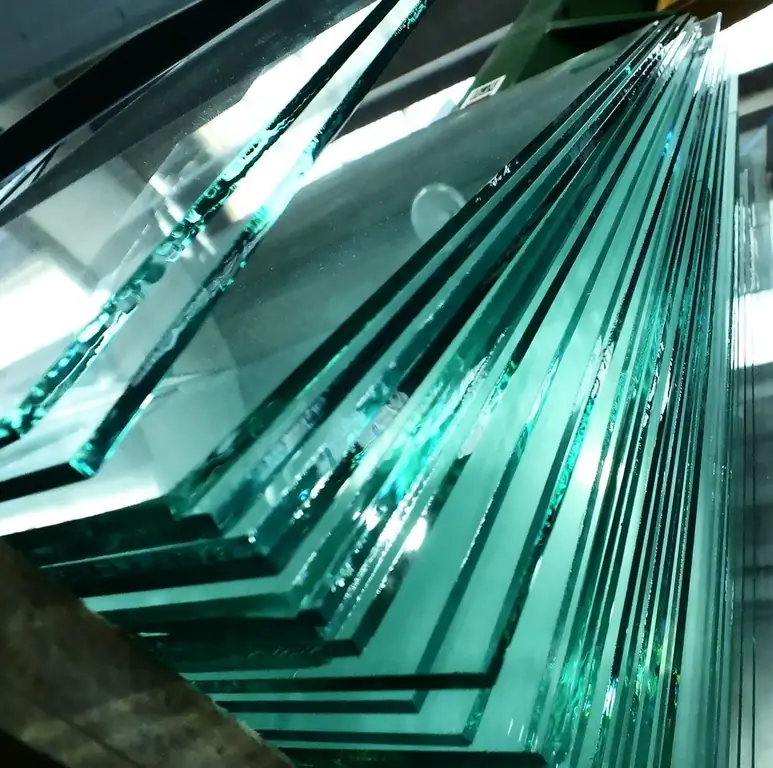

Cooling and flattening the glass surface

The resulting mixture is poured into bathtubs filled with molten tin. The density of the latter is less than the density of hot glass, so it spreads evenly over the bath. At the same time, it is cooled to a temperature of 600 degrees, because the temperature of tin is lower than the temperature of liquid glass. The large roller pulls out the soft glass and pushes it further.

Cutting

The resulting "endless" glass sheet is incised with a diamond. The cutting device moves along the path at an angle. The sheet is fed by constantly moving rollers. The diamond "captures" movements, adjusts and cuts even sheets. Then one of the rollers rises and the glass is separated along the cut line.

Move glass

The resulting sheets are moved by robots that have vacuum nozzles. They grab the glass and transfer it to the place indicated by the person using the remote control.

We talked about the main stages and technology of transparent glass production. It is more commonly used than color.

Colored glass

To create original stained-glass windows, fragile glass sheets of different colors are needed. Before you make colored glass, you need to choose the desired color. A chemical element is added to the crushed raw materials, which will color the transparent glass. An orange color is obtained by adding cadmium sulfite and zinc white. To create a red tint - selenium. The amount of added substance depends on the color and intensity of staining.

Equipment forworkmanship

The process of glass production is, of course, lengthy, but at present most of the operations are automated. The equipment is varied and expensive.

Main equipment of glass factories:

- vehicles for transporting sand from quarries to conveyors;

- conveyor belts for moving raw materials to sorting places;

- sand washing drums;

- sorters;

- filtering plants;

- installations for mixing components;

- glass furnaces;

- leveling baths or glass sheet stretchers;

- conveyors equipped with rollers for moving glass around the workshop;

- automated diamond sheet cutter;

- pneumatic grippers.

Glass at home

Craftsmen can make glass even at home. First you need to calculate the proportions of the components. Having studied what glass is made of, the composition of the future glass mixture includes: sand, soda, lime, broken glass.

How to make glass at home:

- Preparation of the main components. It is necessary to heat 180 grams of baking soda over a fire until the moisture evaporates. Warm up 400 grams of sifted washed sand on fire, dry. Grind 80 grams of lime. Pour into one bowl. Add 10 grams of boric acid and two table s alt.

- To make glass yourself, you should prepare a container. metal utensils formaintaining integrity in high heat, it is advisable to coat with a mixture of liquid glass and clay in several layers. To do this, mix a few tablespoons of modeling clay with water until it becomes liquid. Then add one or two tablespoons of liquid glass. Cover the dishes with a brush.

- Ignite the coated vessel on gas. Its surface will be covered with convex "pimples".

- Prepare cullet: sift broken dishes. Pour three tablespoons of small glass particles into a cooking dish. Add the rest of the raw material.

- Put the mixture into the fire. You can blow it with a forge. After three to four hours, the mixture will melt to a liquid glass consistency.

Quality standards

There are a lot of types of glass. To determine the quality of each type, state standards have been created, which describe the properties and quality characteristics.

There are GOSTs for quartz, sheet, medical, multilayer, curved, inorganic, optical and other types of glass. They describe production technologies, brands, methods for determining quality, classification.

Glass grades

Large manufacturing companies produce a wide range of sheet glass types. This is due to the popular glazing of large office and retail buildings in major cities. Therefore, production workers often use GOST No. 111-90 “Sheet glass. Specifications.”

By purpose, glass is divided into the following grades:

- M1 - mirrorimproved. The thickness of products is not more than 6 mm and not less than 2 mm. Designed for car windshields, quality mirrors.

- M2 - mirror. Used for the production of mirrors, glasses in public transport.

- M3 - polished technical. They produce decorative elements of furniture, mirrors.

- M4 - polished window. Serves for high-quality glazing of structures of translucent, safe glass of vehicles.

- M5 - unpolished window improved. Used for agricultural vehicle windows.

- M6 - unpolished window. Used to create translucent structures.

- M7 - polished showcase. The thickness is from 6.5mm to 12mm. Used in the design of shop windows, stained-glass windows.

- M8 - unpolished showcase. Shop windows and lanterns are made from it.

Classification of glass products

Around a person is full of objects made of glass or with its inclusions. You can generalize them according to the intended use.

Main glass product groups:

- Household products. Which, in turn, are divided into household, artistic and decorative, kitchen utensils. Household products are used to preserve and store food. Artistic and decorative - have high aesthetic properties and serve to decorate the interior. Kitchen utensils are made of borosilicate or glass-ceramic glass, which has fire-resistant properties. Therefore, the range is represented by braziers, pots,ducklings.

- Building - glass used in construction. The production includes glass for windows, showcases, stained-glass windows, double-glazed windows, glass blocks, and other building products.

- Technical - glass with a narrow specialization. Includes medical optical, laboratory glassware, transport used in electrical, car parts.

Glass application

Glass products are used in many areas of human activity. In some, its hardness is important, in others - transparency, quality is valued equally everywhere.

Glass applications:

- Optics. Priority is given to the transparency of future optical elements. Used in scientific, military, aerospace and consumer optics.

- Transparent glass. Actively used in construction for the construction of light structures.

- Colored glass is the basis for creating stained-glass windows and other mosaics.

- Art glass. This type is used to create original jewelry, interior elements.

- Glass enamel. It is a durable material with high abrasion resistance. It is actively used to cover ceramic tiles, bathtubs, faience sanitary ware, galvanized bathtubs.

- Fiberglass, fiberglass. They are used to produce glass wool, fiberglass and other materials.

- Optical fiber. It is used to make special threads for communication, the Internet, television networks.

- Photochromicglass. This type of glass is used to protect from light. Used in the manufacture of sunglasses, to darken windows in public transport.

- Dielectric glass - widely used for the production of insulators in the electrical industry.

Glass production sites

Glass production has been preserved in many countries of the former USSR. This is due to the availability of raw materials and the relative ease of production.

Glass production in Russia is represented by the following companies:

LLC "BSZ" - Boyar glass factory, the largest manufacturer. Produces tempered, tinted glass and triplex. The products are used in the automotive industry: for windshields, side windows in cars. Located in the city of Bor, Nizhny Novgorod region.

JSC "Salavatsteklo" produces sheet glass for the production of commercial equipment, furniture and transport industries. The company produces glass bottles. Production is located in the Republic of Bashkortostan, the city of Salavat.

JSC "Saratovstroysteklo" produces glass sheets using the modern fleet method. The company manufactures glass grades M1, M4 and M7. The products of the Saratov glass factory were used in the construction of the Kremlin Palace of Congresses, the Rossiya Hotel and a number of others.

LLC "Pilkington Glass" is a British manufacturer of glass products in the Moscow region. Produces a specialized line of solar control glass thatwidely used in building glazing. The products have high noise insulation properties, therefore they are used for glazing buildings near roads and railway lines.

Guardian Steklo Ryazan LLC is a Russian enterprise, in the production of which the latest technologies and equipment are used. The company manufactures fiberglass thermal insulation, solar control and multifunctional, energy-saving glass. The line for the production of mirrors with a painted surface is in operation.

JSC "Vostek" - a production complex that produces glass sheets for use in the production of windows and greenhouse glazing. The joint-stock company produces baguette, frosted, tempered glass. Engaged in the restoration of Catholic churches and other valuable buildings, operates a line of automatic glass cutting. Production is delivered to England, Holland, Germany. Production is located in the City of St. Petersburg.

CJSC Symbol, a Moscow-based company, manufactures sheet glass for the automotive industry and offers a wide range of impact-resistant laminated glass.

Glass can be made both in large industrial production and at home. The main active ingredient is fine quartz sand. The most important type of equipment is the melting furnace, the processes in which are fully automated. A person almost effortlessly receives material for a wide range of applications - from the production of double-glazed windows to the production of fiber optic threads.

Recommended:

Wood processing technology and production of wood products

Wood is an unusual and especially valuable material. For all its familiarity, it has an amazing set of technical and physical properties that a person cannot repeat with the help of synthetic substitutes. This is due to the extensive use of blanks made of natural wood in a variety of industries. Modern wood processing technologies and the production of wood products in general make it possible to provide people with furniture, building materials, decorations, utensils, etc

Product is.. Production of products. Finished products

The economy of every country is based on industrial enterprises that produce products or provide services. The number of products manufactured by an enterprise is an indicator for assessing the effectiveness of a company, industry, and even the entire national economy

Business idea: production of bricks. Technology and installation for the production of bricks

You can create your own business that will meet your requirements and also become a source of income. However, in order to obtain high-quality bricks, it is necessary to comply with the technical conditions and adhere to the manufacturing process. The production of bricks at home does not involve the use of expensive equipment. The most important condition is the correct preparation of raw materials

Production of wooden windows: production technology

It is impossible to imagine a living space without a window, which is a conductor between the inner and outer space. Windows are made from different materials. But how wooden windows are made, and what types of them exist, read the article

JSC "Bor glass plant" (BSZ): description, products and production features

JSC "Bor glass plant" is the leading manufacturer of auto glass in Russia. Since 1997 it has been owned by the AGC Europe group of companies. The company also produces: dishes, mirrors, polished glass and other products