2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:49

If you are seriously engaged in repairs in your apartment or house and plan to plaster the walls, level the floor, then you need to figure out how to make a cement mortar. Of course, if you are thinking of hiring builders, then delving into the intricacies of the process is not at all necessary. But if you decide to do all the dirty work yourself, but you are not a specialist, then it is better to study the theoretical part first.

For any work you will need fresh cement - this is a special binder that becomes stone-like when hardened. Please note that if it lies down for more than six months, it can absorb moisture, and it will simply become impossible to use it. In order to make a mortar for plaster, you need to find out what cement is made of. To prepare it, you should first mix the purchased binder with sand. The proportions will depend solely on the brand you purchased. So, for M-200 cement, for each of its kilograms, 3.5 kg of sand is needed, and for M-400, 5 kg will be needed. By the way, not only the amount of the resulting mixture, but also its strength will depend on the brand. For example, for the construction of various military facilities, includingmissile silos or bunkers, use the M-600.

It is important not only to know the necessary proportions, but also the technology of how to make a cement mortar. After preparing the dry ingredients, pour them into the kneading container in a small layer. Only then add water and mix everything thoroughly until a homogeneous mixture is obtained. The quality of the solution is checked as follows: it should stick in pieces to the shovel, which interfered with it. If it completely drains from it or, conversely, envelops, then this batch is unsuccessful. In the first case, it turned out to be too liquid (skinny, as the builders also call it), and in the second - thick (fat).

Knowing what cement is made of, you can prepare all the necessary materials in advance in the right quantities. By the way, it is desirable to know the proportions even in cases where builders will do all the work for you. This will help to avoid unnecessary costs, because you will be able to control the consumption of materials yourself.

If you want to learn not only about the technology for making a mixture for plastering, but also about what cement is made of, then you will be interested in the following. The production of this material is quite an environmentally harmful, labor-intensive and costly process. It begins with the most expensive stage - the extraction of raw materials, which include carbonate rocks: limestone, chalk and others. Raw materials extracted from the bowels of the earth are crushed and ground.

At the next stage, carbonate rocks are mixed with other components and fired. ATas a result, clinker is formed. If we continue to understand what cement is made of, it will become clear that at this stage its basis was created. Its further production will depend on the raw material base used and the quality of the source material. The industry has developed 3 methods for the manufacture of cement: wet, dry and combined. The first option is used in cases where chalk, clay and various iron-containing additives serve as raw materials. Grinding the mixture with this method takes place in an aqueous medium, and the output is a suspension with a moisture content of about 30-50%. It is fired in a special oven, after which it is ground into powder. But with the dry method, the components are dried before grinding.

Recommended:

Payment of contributions for major repairs: calculation of the amount, payment rules, terms and benefits

Paying maintenance fees is the responsibility of every apartment owner in an apartment building. The article describes how the fee is set, what benefits are offered to different categories of the population, and what are the consequences of not paying

What are different types of cement made of?

Cement is one of the most common and important building materials, without which modern construction cannot do. As a component, it is used for the manufacture of various solutions and mixtures. All buildings erected over the past 200 years were created with his participation. What is made of cement, what types exist and where are they used? Let's try to answer all these questions

What is milk made of? How is milk powder made?

Surely everyone is concerned about the question of what milk is made of. In this article we will try to find answers to it and learn a lot about this product familiar from childhood

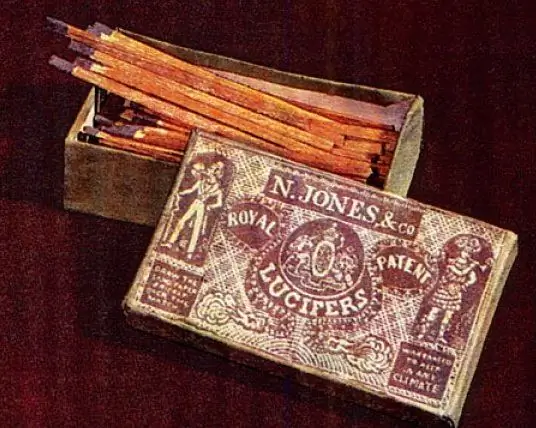

How were matches made before and how are they made today? Swedish matches

The article is devoted to the history of the creation of matches - from their very first prototypes to modern ones. It also tells about the famous Swedish matches, the evolution of the chemical components of the match head and stickers for the box

Preparing the onion for planting on the head. Preparing onion sets before planting. Preparing the soil for planting onions in spring

Each of the housewives knows that there should always be onions in the house. This product is added to almost any dish, it can bring great benefits to our body