2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:27

At present, the railway communication is developed quite strongly. Passenger transport, delivery of goods or mail are industries that are used constantly and everywhere. However, in order for everything to work like clockwork, it is necessary to monitor the condition of each car and its components.

Device

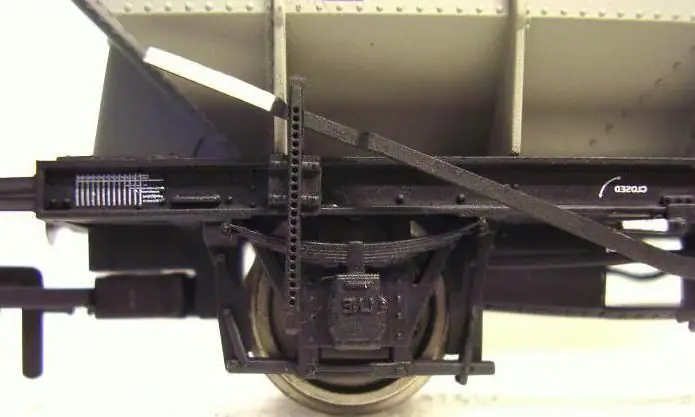

The axle box is one of the elements of the running gear of the car. The purpose of this part is to transfer the gross load from the car to the axle neck. At the same time, this unit is designed to accommodate lubricating devices and the lubrication itself. Also, this part serves as a connecting element between the wheelset and the bogie frame, the assembly protects the necks from contamination or damage. And the last function that the nodes perform is to limit the longitudinal or transverse displacement of the pair relative to the cart.

It is also important to note that the node is unsprung and therefore it will rather harshly perceive any dynamic vibrations emanating from the track, which will definitely arise due to the movement of vehicles.

Assembly with bearings

Currently, there are many different types of axleboxes. There are elements withbearings, which can be divided into two groups precisely according to these details. There are nodes with cylindrical and spherical roller. Currently, these two types of axleboxes with these types of bearings are used throughout the CIS.

It is worth noting that the production of these components with spherical ones has not been carried out since 1964, and at present there are only about 5% of trains whose cars have nodes with this type of device. In addition, when these parts fail, they are replaced not with similar ones, but with units with a cylindrical bearing type, therefore this small percentage is constantly decreasing.

Currently, the main type of axlebox is the one that has a cylindrical roller type bearing on a hot suspension.

Roller bearings

Today, all types of passenger and freight cars are equipped with roller bearings. Also, all old passenger cars and almost all (about 80%) freight cars were transferred from old models to roller ones. In addition, since 1982, all axlebox units of the car have been equipped with the roller type. This decision is justified by the fact that the quality and reliability of operation of this type of part is higher than that of plain bearings. This is clearly visible if we take into account such an indicator as the delay or uncoupling of wagons due to heating of this part. Practice has shown that roller elements heat up about half as much as their previous counterparts. Another advantage of the wheeledaxle box equipped with roller bearings, in that they reduce the specific resistance of the entire car by about 7-10 units at the moment when the train starts moving. And the fuel consumption or electricity consumed by the train will be reduced by 10%.

Passenger car assembly

At present, a typical axle box for a passenger car is also used, in which the bearings are fastened by means of a washer. In order to structurally correctly perform the device of the axle box of a freight car or a passenger car, it is necessary to follow the scheme for supporting the bogie frame on a specific node. It is also worth noting that the body for this part can be made in different ways. Production can be carried out with support brackets, as well as a solid labyrinth part, or with several jaw slots, and the labyrinth part will be pressed.

Knot installation

In order to carry out the installation of axle box assembly with a roller bearing, it is necessary to perform some preliminary operations. Such operations include the search for a suitable labyrinth ring, as well as the bearings themselves. The main characteristic by which the ring is selected is interference, that is, it is the difference in the positive direction between the difference in the diameter of the inner landing part and the diameter of the pre-hub part of this axle. This indicator should be in the range from 0.08 mm to 0.15 mm. The choice of roller bearings should also be carried out according to the tightness, but the diameter of the inner ring is important here. The parameter mustbe in the range from 0.04 mm to 0.065 mm. It is also important here to take into account the axial clearance and the difference between the radial ones, the indicator of which should be equal to 0.2 mm.

The assembly process begins with the fact that it is necessary to heat the labyrinth ring to a temperature of 125-150 degrees Celsius. The ring is installed on the pre-hub part of the axle. Next, you need to wait for complete cooling and, using a curved square, check the perpendicularity of the installation. It is also necessary to use a feeler gauge to ensure that the ring is properly seated. After that, they proceed to the installation of the guide cup, which is screwed onto the axle thread and is designed to protect it from damage that may be caused by further installation of the inner bearing rings.

Cassette bearings

At present, if we turn to the countries of Europe, then in their high-speed trains axlebox units with double-row tapered roller bearings are installed. The speed of movement of these vehicles is in the range from 200 to 350 km/h. The widespread use of cassette bearings has become possible due to the fact that they have a number of the following advantages:

- Adapted to high-level combined loads. In turn, this provides more mileage that the train can go, and also guarantees 100% operation of the train throughout the entire warranty period, if the axle box is inspected in a timely manner.

- This type of bearings is completelymeets the conditions required to achieve high train speeds.

- The design of this assembly model is more compact.

Wheelset

In order to guarantee safety, it is necessary to periodically check the serviceability of the axle boxes and their pairs. It is important to know that during the first inspection of the pair and if it becomes necessary to grind it, this can be done without removing the axle box. If, after carrying out this operation, defects appear again by the next inspection, which will need to be eliminated by turning the pair, then it is no longer possible to do without removing the axle box.

After the repair is completed or the process of complete inspection of the wheelset is completed, it is painted black. It is also worth noting that the junctions of the hubs with the hub axles are also painted, but already with white paint. Coloring is carried out around the entire circumference of the joint.

Bearing fit

Currently, three methods of fitting bearings on the axle are known and used - hot, sleeve, pressed. However, in modern type axleboxes, only two of the three methods are used - this is hot and pressing.

It's also important to know that once the complete assembly process is completed, the assembly is filled with grease. If we talk about the lubricant that is used for roller bearings, then since the beginning of 1973 it has been LZ-TsNII. The main purpose of this mixture includes such functions as: to provideresistance to wear, corrosion, to ensure the absence of scuffing phenomena that occur during the operation of the bearing.

Recommended:

Mine well: device, sanitary requirements, value

Description of the construction of shaft wells. What are the requirements for structures during construction and operation. Features of concrete, plastic, wood and brick products. Necessary conditions for the start of construction or restoration. Sanitary standards for the operation of mine wells

Aircraft device for dummies. Aircraft device diagram

Few people know how an airplane works. Most don't care at all. The main thing is that it flies, and the principle of the device is of little interest. But there are people who cannot understand how such a huge iron machine rises into the air and rushes at great speed. Let's try to figure it out

Axlebox units: description, malfunctions, design and repair

Currently, railway communication within the country and between countries is quite well developed. The fact that trains carry a large number of people or valuable goods suggests that they must always be in perfect technical condition in order to avoid huge problems. One of the most important elements is the axle box

Wagon inspector: job description

There are many professions in the railway industry. Some of them are on everyone's lips, such as the driver, the conductor or the head of the train. But there are also little-known, but no less significant speci alties. Among them stands out the wagon inspector, who is an important link in the safety chain on the railway

Wagon economy: structure and functions

The railway network is formed by an extensive complex of technical means and structures that ensure the stable functioning of the transport system. To rationalize the technological processes of maintenance, some components of the common infrastructure are allocated to independent objects with autonomous control