2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:32

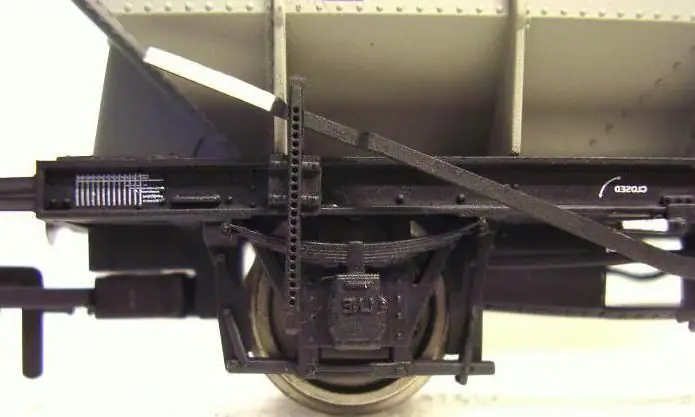

Axlebox units serve to transfer the pressure of the car, which it creates, acting on the necks of wheel sets, as well as to limit the longitudinal and cross section of this pair.

Node device

If we talk about the arrangement of the axle box, it is important to immediately note that it is the most important part of the wheel pair of the car. The installation or dismantling of this element also takes place in conjunction with the installation or replacement of the wheelset. In addition to what has been described above, the assembly is also intended to establish a strong connection between the pair of wheels and the bogie frame. Engagement is carried out through nadbuksovye spring suspension. Another task for which the axle box of the car is intended is the storage of grease for roller bearings. In other words, this detail is a kind of container. This element also limits the unnecessary movement of the pair of wheels relative to the bogie frame and transfers the load of the mass of the car to the axle neck.

Compoundknot parts

The axle box of a freight car consists of a large number of parts.

The first part is a body with tides, which are intended for spring suspension.

The second element of the node is a labyrinth ring. The location of this part is the rear cover of the box body. It is pressed onto the pre-hub part of the axle.

The next item is roller bearings. This assembly element consists of an inner ring, has a cylindrical roller cage, and has an outer ring.

Next, a small piece called a thrust ring sits between the roller bearings.

Another device that is designed to install the outer bearing is the retaining ring.

A Belleville washer or slotted nut is needed to make the end mount.

The axle box also has a mounting cover, felt and rubber gaskets between the parts and an inspection cover.

All these elements are connected into a single node, which was called the box.

Connection method

Currently, there are two types of attachment of the node to the trolley. They are called jawless and jawless.

If we talk about the second version, then in this case the body of the unit, for example from a passenger car, will have two brackets that are designed to carry out such a unit installation procedure as an over-axle spring suspension. The fastening parts of the assembly have holes through whichthey are attached to the frame of the trolley with the help of a detail such as pins. In such cases of installation, the labyrinth part of the axle box is cast together with its body and forms a one-piece structure.

It is very important to monitor the heating temperature of the axle box while driving, and therefore the upper part of the body has a non-through hole, which is designed specifically for mounting the SKNB. The abbreviation SKNB is deciphered as a signaling device for controlling the heating of axle boxes. It is worth adding that during installation in this way, the labyrinth ring is pressed on and installed only with preliminary heating of this part to a temperature of 125-150 degrees Celsius.

What kind of axle box malfunctions can occur?

Since this element has many components, as well as parts that move, their wear, abrasion and failure are quite logical. And because passenger or freight cars carry a large number of people or valuable material, the failure of the node will entail almost disaster.

Faults include the following:

- Destruction of the bearing. Most often this is due to the fact that the roller jams, and it stops making a rotational movement.

- There may be a problem such as end mount failure. Most often this is due to the fact that the nut comes off the axle neck or the bolt heads break off.

- Possible malfunction such as rotation of the inner ring of the bearing or fracture of the axle neck.

- Faultythe moment at which the heating temperature of the axle box exceeds 70 degrees Celsius is also considered.

Signs of node failure

There are a number of signs by which it can be determined that the performance of this element of the car is broken and inspection and repair are required. Such signs include a rattle or tapping, which periodically becomes audible during the movement of the train.

Because the bearings inside the axle box are metal, the sound of these items churning while moving is also a sign of a broken assembly. Incidents such as leakage of grease from the labyrinth ring, scale or discoloration on the axle box, the presence of smoke from the assembly or its smell after the car has stopped are also signs that the axle box is faulty and needs repair. Too high temperature in the upper part of the element also belongs to the malfunctions of the axle box assembly. It is easier to notice this particular sign than the others, since this parameter is controlled and an automatic alarm is triggered.

Traffic safety

The traffic safety of the entire train is highly dependent on the proper operation of this node. Due to the fact that the composition develops a rather high speed, the heating temperature of the axle box can increase at a very high speed - up to 20 degrees Celsius per minute. Due to severe overheating, the chance of such a breakdown as ring rotation or jamming of the entire part increases. The occurrence of one of these twofailure of the axlebox assembly will cause the wagon to derail.

Electric locomotive box

It is necessary to carry out repair work either within the time period established by the technical documentation, or in the event of a breakdown. There are practically no differences between the designs of this element of a freight car or an electric locomotive, and therefore an example of repairing an axlebox assembly can be considered on such a model of an electric locomotive as VL80.

Assembling the assembly begins with the fact that the nut is unscrewed, and then the bolt is knocked out. It is very important to check its thread. It is worth noting that washing all parts of the axle box is also an important part of the repair, as contamination will cause the bearings to stop rotating. But here it is necessary to take into account the fact that after the end of the washing before disassembling the element, more than 6 hours should not pass. This is justified by the fact that prolonged exposure to moisture on the parts will lead to corrosion too quickly.

What to check when repairing

It is necessary to subject the bearings of the axlebox assembly and the eyeliner to a very thorough inspection. Those liners that are recognized as suitable for further use must be sent for magnetic flaw detection. Those that are considered no longer suitable for operation are dismantled and transferred to the place of inspection, assembly and formation of eyeliners.

Roller bearings are washed very thoroughly. First, they are washed with soapy emulsion, then washed again in gasoline, after which they need to be wiped dry.napkins. After that, they also undergo procedures such as inspection, measurement and defectoscopy.

When inspecting these elements, it is very important to pay attention to the presence of defects such as traces of overheating, cracks, which most often occur on rings, cages or rollers. It is worth noting that almost 37% of all axle box failures occur due to fatigue failure or wear of the cage centering surface.

Recommended:

Wheel sets of wagons. Malfunctions of wheel sets of railway wagons

The article is devoted to malfunctions of wheelsets in railway transport. Describes common types of wear and deformation, as well as the nuances of maintenance and repair

Condenser units. Repair and operation of industrial electrical equipment

Only capacitor units can protect the circuit from harmonics and interference. In terms of power, the modifications are quite different. Modern models are produced with multi-channel regulators

Gas pumping units: description, device, principle of operation, reviews

From primary production to direct use, gas mixtures go through several technological stages. To optimize transportation and intermediate storage between these processes, the raw material is subjected to compressor compression. Technically, similar tasks are implemented by gas compressor units (GPU) at different nodes of backbone networks

Job description of an electrician for repair and maintenance, rights and obligations

Specialists accepted for this position are workers. To find a job, a person needs to have a specialized secondary education, the profile of which corresponds to the work assigned to the employee

Malfunctions and repair of hydraulic carts: features, device and recommendations

Of course, the operation of any device leads to the fact that it gradually fails. Some parts break, grease dries out, etc. All this also applies to hydraulic carts, the repair of which is quite simple, but you need to know how and when to carry it out