2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:28

Steel is the most common metallic material in the industry, on the basis of which structures and tools with desired properties are made. Depending on the purpose of this material, many of its physical properties, including density, change. In this article, we will consider what steel has a density in kg / m3.

What is steel, and what is it like?

Before giving tables steel density in kg / m3, let's get acquainted with the material itself. Steel in metallurgy is called an alloy of iron with carbon, the content of which does not exceed 2.1 atomic percent. If there is more carbon, then graphite begins to form in the system, which leads to a sharp change in the properties of the alloy. In particular, its hardness and brittleness increase, and plasticity decreases. If there is more than 2.1% carbon, then the alloy is called cast iron.

The main thing to understand is that steel is an alloy of iron with other elements that act as impurities. If iron becomes a non-core component,then this alloy is not steel.

Steels are very different. Thus, a low carbon content leads to the formation of a class of structural materials. Its higher content forms a class of tool steels. In addition to carbon, there are materials alloyed with various elements. For example, adding more than 13% chromium leads to the formation of stainless materials, and a large content of molybdenum and tungsten forms a class of cutting steels.

What determines the density of steel?

There are a number of factors that determine the density of steel in kg/m3. These include the following:

- density of iron itself for a given crystal lattice;

- quantity and type of impurities;

- the presence of phases.

Of these factors, the first is the most important, since it is iron that is the basis of the alloys under consideration. As is known, it can exist in two crystal lattices: bcc (body-centered cubic) and fcc (face-centered cubic).

The first type of lattice forms the so-called ferritic steels, the second - austenitic. The fcc lattice is close-packed, while the bcc lattice is looser packing of atoms. However, the density of ferritic steels is generally higher than that of austenitic ones. The reason for this is simple, the fact is that fcc is a stable structure only at high temperatures for pure iron, and all metals expand greatly when heated. The latter leads to a drop in density.

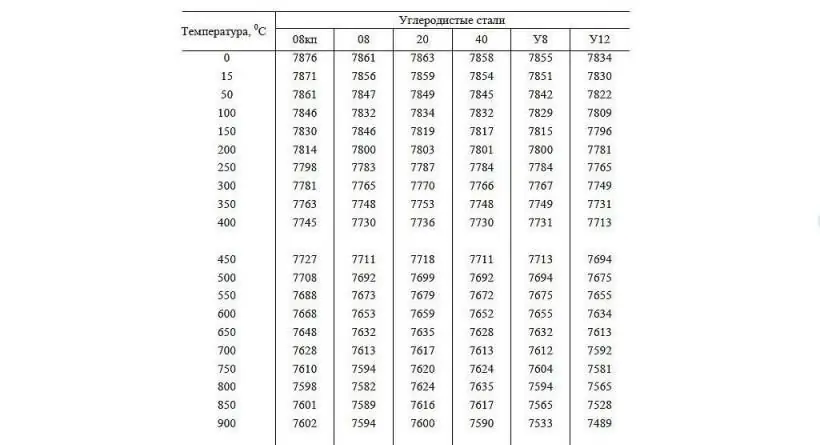

Carbon steels

What is the density of carbon steel? In general, we can say that it is slightly lower than the density of pure BCC iron (7874 kg/m3). This slight decrease is due to the fact that carbon in the bcc lattice occupies octahedral pores. The density of carbon itself in the structures of diamond and graphite is very low, so its addition to iron reduces its average density. Since carbon atoms occupy large octahedral pores, they slightly increase the average lattice parameter, which affects a slight decrease in the considered parameter. Below is a table of steel density in kg / m3, depending on the grade and temperature.

Alloy steels

As mentioned, these include any iron-based alloys that, in addition to carbon, contain other elements, such as chromium, nickel, tungsten, vanadium, and so on. Thus, the density of stainless steel 12X18H9, containing, in addition to chromium, nickel, at room temperature is 7900 kg/m3, which is higher than that of pure BCC iron. If there is no nickel in the "stainless steel", then its density will be lower than that of pure iron, since the chromium atom is lighter than iron.

The densest are high-speed steels. They contain large amounts of heavy metals such as molybdenum and tungsten. Their density can reach 8800 kg/m3.

Recommended:

Carbon is Carbon: description, scope, features and reviews

Carbon is a modern material actively used in a wide variety of industries and other areas of human life. We will talk about this most interesting product in as much detail as possible in the article

Steel weldability: classification. Weldability groups of steels

Steel is the main structural material. It is an iron-carbon alloy containing various impurities. All components included in its composition affect the properties of the ingot. One of the technological properties of metals is the ability to form high-quality welded joints

Food stainless steel: GOST. How to identify food grade stainless steel? What is the difference between food stainless steel and technical stainless steel?

The article talks about grades of food grade stainless steel. Read how to distinguish food stainless steel from technical

Alloy is a homogeneous composite material. Alloy properties

Everyone has heard the word "alloy", and some consider it synonymous with the term "metal". But these concepts are different. Metals are a group of characteristic chemical elements, while an alloy is a product of their combination. In its pure form, metals are practically not used, moreover, they are difficult to obtain in their pure form. While alloys are ubiquitous

Density of crushed stone - gravel, granite, limestone and slag. Bulk density of crushed stone: coefficient, GOST and definition

Crushed stone is a free-flowing, inorganic and granular material obtained by artificial crushing. It is divided into primary and secondary. This is an important fact. Primary - the result of processing natural stone: pebbles, boulders, pumice and other materials. Secondary is obtained by crushing construction waste, such as concrete, asph alt, brick. In this text, we will consider in more detail such a property as the density of crushed stone