2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:26

Advanced technologies today regularly introduce many different novelties into our lives that can greatly simplify it or improve its quality. In particular, this concerns the creation of the latest developments in the chemical industry, the products of which are used in almost every branch of human activity. One such know-how now is the material carbon. We will talk about it in as much detail as possible in the article.

Definition

Carbon is inherently carbon fiber, that is, a composite material with different layers. Simply put, carbon fibers in the form of a web, the shell of which, in turn, is made of thermosetting, polymeric resins. Actually, carbon is today almost all composite materials, the supporting base of which is presented in the form of carbon fibers. However, at the same time, different auxiliary components can be connecting elements.

Cost

Carbon is a very expensive end product, the cost of which is determined by an impressive share of manual labor and a complex technical process in general. To understandhow expensive carbon is, let's compare its cost with steel. So, if one kilogram of steel will cost the manufacturer about $ 1, then the same weight of carbon fiber is 20 times more expensive. To reduce the cost of carbon fiber is possible only through the introduction of full automation of the process of its creation.

Scope of application

Initially, carbon is a material that was created for spacecraft and the automotive industry. However, over time, due to its unique performance characteristics (low specific gravity, high strength), it has found application in other areas such as:

- Aircraft industry.

- Manufacture of various sports equipment, fishing rods, helmets.

- Manufacture of medical equipment and others.

Special Features

Studying what carbon is, let's note its main positive qualities. Products from this material can be molded in almost any configuration. This is because the carbon web has a very high flexibility, which, in turn, provides optimal cutting and cutting. In this case, it is imperative to impregnate the finished product with epoxy resin. Products obtained in this way can be sanded, polished, painted and even flexo printed on them without any problems.

Distinguishing Features

Continuing to consider what carbon is (karbon) we will indicate its unique characteristics. For all types of this carbon plastic, the use of a reinforcing element is common - carbon fibers, the thickness of which is within 0,005-0.01 mm, excellent in tension, but not tolerant of bending and torsion. That is why carbon is a material that is used in the form of a sheet. Rubber is often used for additional reinforcement, which gives carbon fiber a gray tint. In general, carbon is characterized by wear resistance, strength, rigidity and low specific gravity. Its density is from 1450 kg / m3. up to 2000 kg/m3

Subtleties of manufacturing technology

Fibers from carbon filaments are obtained in air during heat treatment. That is, the oxidation of organic or polymeric threads occurs during the day at a temperature of 250 degrees Celsius. Then carbonization is carried out - heating the obtained fibers in an inert gas environment in a temperature range of 800-1500 degrees to prepare the molecular structure for the optimal one. This is followed by graphitization in the same medium, but already at temperatures up to 3000 degrees. This process can be repeated several times to increase the carbon concentration to 99%.

Issue form

Carbon fibers can be either short, cut, or as continuous threads on reels. But, as mentioned above, carbon has poor resistance to bending, then carbon fiber is often formed into a canvas called Carbon Fabric. Moreover, it turns out in the form of a variety of weaves: herringbone, matting, and so on. It happens that the fibers simply intercept before being filled with resin in fairly large stitches. The carrier base is most often epoxy resins, inwhich carbon fibers are laid in layers. A sheet 1 mm thick contains mainly three or four such layers.

Dignity

Carbon has a whole range of undeniable advantages, among which we should point out:

- Small specific gravity. Even aluminum is 20% heavier than the described material.

- Carbon, a combination of carbon and Kevlar, is only slightly heavier than rubber, but much stronger, and under impact only crumbles, but does not shatter into small particles.

- Resistant to high temperatures. Carbon can withstand up to 2000 degrees Celsius.- has good heat capacity and excellent vibration damping.

- Resistant to the phenomenon of corrosion.

- Has a high tensile strength and tensile strength.

- Has an aesthetic appearance and decorative effect.

Flaws

However, compared to metal products, carbon has such negative qualities:

- High sensitivity to point sharp impacts.

- The complexity of the restoration in the event of chips, breaks and various scratches.

- Burnout and fading when exposed to bright sunlight. That is why all things made of carbon fiber are specially varnished or enamelled.

- Sufficiently long-term production of products that require a significant investment of time.

- Problems with recycling and reuse. In the zones of direct contact with the metal, its corrosion begins, therefore, at these points, fixspecial fiberglass inserts.

Opinion of users

In conclusion, we note the reviews of people about the product of the industry described in the article. So what is carbon? This material, according to many users, is very good due to its strength, but at the same time lightness. This was especially appreciated by fishermen who have been using fishing rods for a long time, many of which are based on carbon. Of course, in addition to this, such fishing rods are also good because they have great durability, because they are also characterized by increased wear resistance.

Recommended:

Types of crushed stone: description, characteristics, scope and origin

Crushed stone is a crushed stone and is divided into fractions according to its size. Technical characteristics such as flakiness, density, frost resistance, fraction, radioactivity affect the areas of use of crushed stone and its cost

Heat-resistant glass: manufacturing features and scope

Glass is one of the most ancient and versatile materials. Glass products are all around us, but usually we do not think too much about its characteristics. They can vary greatly depending on the purpose of using the future product. One of the most common types is heat-resistant glass. Let's find out how it differs from the usual one and where it is applied

Flange plugs: scope and design features

Flange plugs are structural elements designed mainly to cover all kinds of end openings of pipeline systems and highways

Carbon ammonium s alts: description, composition, scope

Practically no industry can do without chemically active substances. Additives are used in agriculture, the food industry, during leather dressing, in construction and in many other areas of human activity. Among all their number, a special place is occupied by ammonium carbon s alts, which are universal

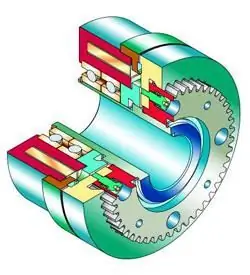

Gear coupling: scope and features

Most mechanisms, turbines, conveyors would not be able to work if they did not use such a small but very necessary part as a gear coupling. Let us consider in more detail the scope and features of gear couplings