2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:31

Scientists have long concluded that to increase the speed of any vehicle, it is necessary to suppress the friction force as much as possible. According to this principle, spaceships fly, which, without environmental resistance, can travel in space for a very long time. It is this feature that underlies the project, known as the “vacuum train of the future.”

The fastest trains

The highest achievement of scientists in the field of high-speed ground movement, as of today, is considered magnetic levitation. Magnetic levitation trains were tested in Japan, England and Germany back in the 1970s. Currently, this type of transport is successfully operated in many states. In this case, by minimizing friction, speeds within 500 km/h are provided. Moreover, such rolling stock is characterized by high efficiency, environmental friendliness and low noise level. At the same time, it should be noted that an increase in the speed of movement entails an increase inaerodynamic drag. Scientists propose to create a vacuum train using a similar approach. The principle of its operation is that the track must pass inside the pipe with pumped out air, so all resistance forces are excluded.

The emergence of the idea of vacuum transport

The concept of building a transatlantic cargo pipeline to deliver goods from Europe to America and vice versa first appeared in the US back in the sixties of the last century. As planned, it was planned to build a pipe in the ocean at a depth of half a kilometer, transportation within which would be carried out by trains moving on a magnetic cushion. Only in 1999, the American engineer Dariel Oster managed to obtain a patent for vacuum pipeline transport technologies, which gave a new impetus to their development.

Project Oster

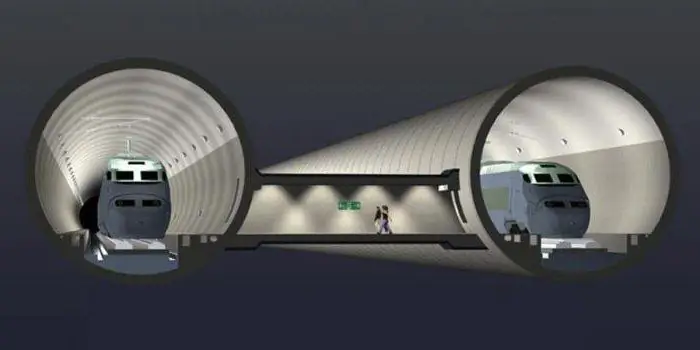

According to Oster's idea, the track should be two elevated pipes (for movement in different directions), each of which is 150 cm in diameter. It is assumed that transport capsules on a magnetic suspension will slide inside. Their diameter will be 130 cm, and the length - 490 cm. Six passengers with a total weight of up to 370 kg will be able to move in the trailer at the same time.

The engine for Oster's vacuum train will consist of a primary (a winding track pipe) and a secondary (the body of the ferromagnetic alloy capsule itself) elements. The minimum gap between them allows the use of an asynchronous linear motor. In the trailer itself you will needinstall only an electrodynamic suspension to provide magnetic levitation, an air regeneration system, seats and miniature batteries designed for virtual windows and TVs. Since the movement of the capsule will occur with virtually no resistance, a significant part of the energy spent on acceleration can be returned during deceleration. The main snag in making this project a reality is that the train in the vacuum tube must move along a perfectly straight track. Otherwise, the electromagnets will have to compensate for the centrifugal force when cornering.

Swiss project

Swiss engineers began to develop something similar back in 1974. Their project went down in history under the name Swissmetro. As planned, the magnetic cushion capsules were supposed to run at a speed of up to 500 km / h. The Swiss vacuum train of the future was designed to connect the main cities of the state (Bern, Zurich, Geneva, Lausanne and Basel). In this case, it was planned to use pipes with a diameter of 180 cm and an eight-seater car for transporting passengers. To date, it is difficult to judge other characteristics, since the project has not been worked out to the end. In 2009, the country's government abandoned this idea.

English train of the future

British engineers in 2002 returned to the project of creating a vacuum train. Their plans are simply grandiose, because the inventors intend to create a network that will replace the rail and roadtransport. To do this, it is necessary to build a whole web of pipes throughout the country. In this case, the capsules will be designed for a maximum of two passengers located in the prone position. Unlike previous projects, here the rolling stock must move along the rails at speeds up to 420 km/h. The electric motors located on the trolleys will be powered by a contact rail. The main drawback that the English vacuum train has, according to the developers, is associated with high energy costs for transporting one passenger, compared to previous projects. On the other hand, its main advantage lies in the relatively low cost of building a transport network.

Hyperloop Project

The most promising is the project of the train of the future, which is called Hyperloop. The idea of its creation in 2012 was suggested by the American billionaire Elon Musk. Initially, the project was talked about as the fifth mode of transport, but it did not go beyond discussions on television. After it became known about the plans of the government to build a high-speed railway line between Los Angeles and San Francisco, the businessman took up the implementation of his concept. The Hyperloop project is an overland pipeline in which a vacuum train can travel at speeds ranging from 400 to 1220 km/h. In August 2013, the idea was officially presented to the general public in a 58-page presentation.

Working principle

The main idea of the Hyperloop project is the maximum cheapness of creating a transport network frompipes and further operation. In this regard, it was based on such a model as a vacuum train. In the USA, according to the inventor, it is necessary to build a network of closed parallel tracks that will connect at the end points of the routes. To create a vacuum in them and maintain it, steel pipes 25 mm thick and pumps with low power are enough. Inside them, Elon Musk suggests launching capsules up to 30 meters long. The first businessman wants to connect San Francisco and Los Angeles.

According to the developer, it will not work to create an absolute vacuum in the pipes. In this regard, air masses will be directed under the bottom of the rolling stock through special nozzles in its bow. This will create an air cushion and save significant funds needed for the implementation of the electromagnet. To recharge the engine, due to which the capsule will be set in motion, an aluminum rail 15 meters long will be installed on the floor of the pipe every 110 km.

Options for the functioning of the system

The presentation considers the passenger and passenger-cargo version of the system. In the first case, it is proposed to build a pipe with a diameter of 2.23 m. The vacuum train running inside will be able to carry up to 28 passengers in one trip. The second option involves the use of a pipeline with a diameter of 3.3 m. In this case, it will be possible to transport three additional cars in each capsule. It should be noted that according to the Elon Musk project, trains will departevery half minute.

Cost-efficiency and testing

The Hyperloop project can be called very effective. The developers intend to fully meet its needs at the expense of solar and wind energy. They plan to sell all of its surplus, earning about $ 25 million annually. According to Elon Musk, a one-way fare would have to be about $20. In this case, the project will pay off in twenty years.

The first tests of the vacuum train took place in May 2016. To this end, a special test site was built in the desert near Las Vegas. The trolley, using electromagnets, first accelerated to a mark of 180 km / h, after which it gradually stopped.

Safety

The developers were especially careful about security. The movement of the capsule will not affect the comfort of passengers in any way. It feels like its acceleration will not differ from the jog of the plane before takeoff, and then - a quiet glide and no turbulence. Elon Musk claims that a vacuum train cannot derail or fall from a height, so it should be considered one of the safest modes of transport. In the event of a power outage, the capsule is equipped with batteries, the power of which is enough to sustain passengers for 45 minutes, in other words, for the entire route. After all, most people are very comfortable with airliner travel, despite the fact that the means of escape in case ofdisasters in them are highly doubtful.

Finishing

Creating a vacuum train, no doubt, requires huge financial costs. In addition, before the implementation of the project, it is necessary to solve many more technical problems. However, in our time, given the constant development of technology, the possibility of implementing this venture does not look as vague as several decades ago. In this regard, one should not be surprised when trains, which are faster than modern supersonic aircraft, will soon be used to transport passengers and goods.

Recommended:

Electric locomotive 2ES6: history of creation, description with photo, main characteristics, principle of operation, features of operation and repair

Today, communication between different cities, passenger transportation, delivery of goods is carried out in a variety of ways. One of these ways was the railroad. Electric locomotive 2ES6 is one of the types of transport that is currently actively used

Vacuum lifter: characteristics and working principle

Vacuum handling systems are widely used in various industries and construction. With the help of such devices, typical manipulations with various materials within the framework of logistics and production processes are reliably and safely performed. For quick and frequent high- altitude movement, a vacuum lifter is used, which can have various performance characteristics and design

Ultrasonic testing of welded joints, methods and technology of testing

Ultrasonic testing - advanced technology for the study of welding joints and seams. It will be discussed in this article

Low pressure heaters: definition, principle of operation, technical characteristics, classification, design, operation features, application in industry

Low pressure heaters (LPH) are currently used quite actively. There are two main types that are produced by different assembly plants. Naturally, they also differ in their performance characteristics

Gas piston power plant: the principle of operation. Operation and maintenance of gas piston power plants

Gas piston power plant is used as a main or backup source of energy. The device requires access to any type of combustible gas to operate. Many GPES models can additionally generate heat for heating and cold for ventilation systems, warehouses, industrial facilities