2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:30

Metrology is the science of measurements, means and methods of ensuring their unity, as well as ways to achieve the required accuracy. Its subject is the selection of quantitative information about the parameters of objects with a given reliability and accuracy. The regulatory framework for metrology is standards. In this article, we will consider the system of tolerances and landings, which is a subsection of this science.

The concept of interchangeability of parts

In modern factories, tractors, cars, machine tools and other machines are produced not by units or tens, but by hundreds and even thousands. With such volumes of production, it is very important that each manufactured part or assembly fits exactly into its place during assembly without additional locksmith adjustments. After all, such operations are quite laborious, expensive and take a lot of time, which is not acceptable in mass production. It is equally important that the parts entering the assembly allow for replacement.to other common purposes with them, without any damage to the functioning of the entire finished unit. Such interchangeability of parts, assemblies and mechanisms is called unification. This is a very important point in mechanical engineering, it allows you to save not only the cost of designing and manufacturing parts, but also production time, in addition, it simplifies the repair of the product as a result of its operation. Interchangeability is the property of components and mechanisms to take their places in products without prior selection and perform their main functions in accordance with the specifications.

Mating Parts

Two parts, fixed or movably connected to each other, are called mating. And the value by which this articulation is carried out is usually called the mating size. An example is the diameter of the hole in the pulley and the corresponding shaft diameter. The value by which the connection does not occur is usually called the free size. For example, the outer diameter of the pulley. To ensure interchangeability, the mating dimensions of parts must always be accurate. However, such processing is very complicated and often impractical. Therefore, in technology, a method is used to obtain interchangeable parts when working with the so-called approximate accuracy. It lies in the fact that for different operating conditions, nodes and parts set the allowable deviations of their sizes, under which the impeccable functioning of these parts in the unit is possible. Such offsets, calculated for a variety of operating conditions, are built in a givena certain scheme, its name is "a unified system of tolerances and landings".

The concept of tolerances. Quantity characteristics

The calculated data of the part supplied on the drawing, from which the deviations are counted, is commonly called the nominal size. Usually this value is expressed in whole millimeters. The size of the part, which is actually obtained during processing, is called the actual size. The values between which this parameter fluctuates are usually called the limit. Of these, the maximum parameter is the largest size limit, and the minimum parameter is the smallest. Deviations are the difference between the nominal and limit value of a part. In the drawings, this parameter is usually indicated in numerical form at a nominal size (the upper value is indicated above, and the lower value below).

Entry example

If the drawing shows the value 40+0, 15-0, 1, then this means that the nominal size of the part is 40 mm, the largest limit is +0.15, the smallest is -0.1. The difference between the nominal and maximum limit value is called the upper deviation, and between the minimum - the lower one. From here, the actual values are easily determined. From this example it follows that the largest limit value will be equal to 40+0, 15=40.15 mm, and the smallest: 40-0, 1=39.9 mm. The difference between the smallest and largest limit sizes is called the tolerance. Calculated as follows: 40, 15-39, 9=0.25mm.

Gaps and tightness

Let's considera specific example where tolerances and fits are key. Suppose we need a part with a hole 40+0, 1 to fit on a shaft with dimensions 40-0, 1-0, 2. It can be seen from the condition that the diameter for all options will be less than the hole, which means that with such a connection, a gap will necessarily occur. Such a landing is usually called a movable one, since the shaft will rotate freely in the hole. If the part size is 40+0, 2+0, 15, then under any condition it will be larger than the hole diameter. In this case, the shaft must be pressed in, and there will be an interference in the connection.

Conclusions

Based on the above examples, the following conclusions can be drawn:

- Gap is the difference between the actual dimensions of the shaft and the hole, when the latter is greater than the first. With this connection, the parts have free rotation.

- Preload is usually called the difference between the actual dimensions of the hole and the shaft, when the latter is greater than the first. With this connection, the parts are pressed in.

Fits and accuracy classes

Landings are usually divided into fixed (hot, press, easy-press, deaf, tight, dense, tense) and mobile (sliding, running, movement, easy-running, wide-running). In mechanical engineering and instrumentation, there are certain rules that regulate tolerances and landings. GOST provides for certain accuracy classes in the manufacture of assemblies using specified dimensional deviations. From practiceIt is known that the details of road and agricultural machines without harm to their functioning can be manufactured with less accuracy than for lathes, measuring instruments, and automobiles. In this regard, tolerances and fits in mechanical engineering have ten different accuracy classes. The most accurate of them are the first five: 1, 2, 2a, 3, 3a; the next two refer to medium accuracy: 4 and 5; and the last three to rough: 7, 8 and 9.

In order to find out what accuracy class the part should be made to, on the drawing, next to the letter indicating the fit, put a number indicating this parameter. For example, marking C4 means that the type is sliding, class 4; X3 - running type, class 3rd. For all landings of the second class, a digital designation is not put, since it is the most common. You can get detailed information about this parameter from the two-volume reference book "Tolerances and Fits" (Myagkov V. D., 1982 edition).

Shaft and hole system

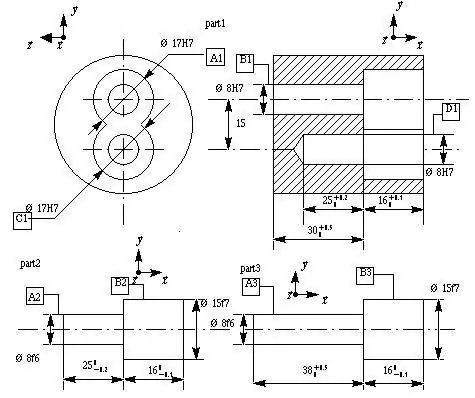

Tolerance and fits are usually considered as two systems: holes and shafts. The first of them is characterized by the fact that in it all types with the same degree of accuracy and class refer to the same nominal diameter. Holes have constant values of limit deviations. A variety of landings in such a system is obtained as a result of changing the maximum deviation of the shaft.

The second of them is characterized by the fact that all types with the same degree of accuracy and class refer to the same nominal diameter. The shaft has constant limit valuesdeviations. A variety of landings is carried out as a result of changing the values of the maximum deviations of the holes. In the drawings of the hole system, it is customary to designate the letter A, and the shaft - the letter B. Near the letter, the sign of the accuracy class is placed.

Examples of symbols

If "30A3" is indicated on the drawing, this means that the part in question must be machined with a hole system of the third accuracy class, if "30A" is indicated, it means using the same system, but the second class. If the tolerance and fit are made according to the shaft principle, then the required type is indicated at the nominal size. For example, a part with the designation "30B3" corresponds to the processing of the shaft system of the third accuracy class.

In his book, M. A. Paley (“Tolerances and Fits”) explains that in mechanical engineering the principle of a hole is used more often than a shaft. This is due to the fact that it requires less equipment and tools. For example, in order to process a hole of a given nominal diameter according to this system, only one reamer is needed for all landings of this class, and one limit plug is needed to change the diameter. With a shaft system, a separate reamer and a separate plug are required to ensure each fit within the same class.

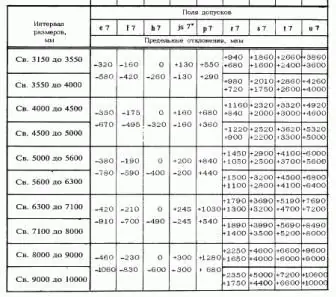

Tolerances and fits: deviation table

To determine and select accuracy classes, it is customary to use special reference literature. So, tolerances and fits (a table with an example is given in this article) are, as a rule, very small values. Forin order not to write extra zeros, in the literature they are designated in microns (thousandths of a millimeter). One micron corresponds to 0.001 mm. Usually, the nominal diameters are indicated in the first column of such a table, and the deviations of the hole are indicated in the second. The rest of the graphs give different sizes of landings with their corresponding deviations. The plus sign next to such a value indicates that it should be added to the nominal size, the minus sign indicates that it should be subtracted.

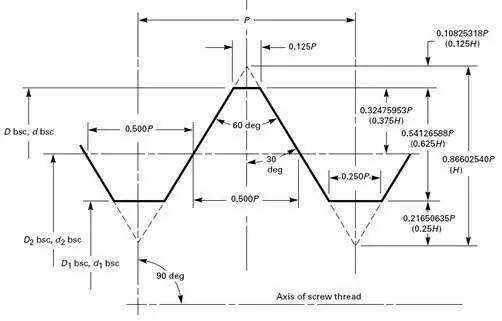

Threads

Tolerance and fits of threaded connections must take into account the fact that the threads are mated only on the sides of the profile, only vapor-tight types can be an exception. Therefore, the main parameter that determines the nature of the deviations is the average diameter. Tolerance and fits for the outer and inner diameters are set so as to completely eliminate the possibility of pinching along the troughs and tops of the thread. The errors of reducing the outer dimension and increasing the inner dimension will not affect the make-up process. However, deviations in thread pitch and profile angle will cause the fastener to jam.

Gap thread tolerances

Tolerance and clearance fits are the most common. In such connections, the nominal value of the average diameter is equal to the largest average value of the thread of the nut. Deviations are usually counted from the profile line perpendicular to the thread axis. This is determined by GOST 16093-81. Tolerances for the thread diameter of nuts and bolts are assigned depending on the specified degree of accuracy (indicated by a number). Acceptedthe next series of values for this parameter: q1=4, 6, 8; d2=4, 6, 7, 8; D1=4, 6, 7, 8; D2=4, 5, 6, 7. Tolerances are not set for them. Placing the thread diameter fields relative to the nominal profile value helps to determine the main deviations: the upper ones for the external values of the bolts and the lower ones for the internal values of the nuts. These parameters directly depend on the accuracy and connection step.

Tolerances, fits and technical measurements

For the production and processing of parts and mechanisms with specified parameters, a turner has to use a variety of measuring tools. Usually, for rough measurements and checking the dimensions of products, rulers, calipers and inside gauges are used. For more accurate measurements - calipers, micrometers, gauges, etc. Everyone knows what a ruler is, so we won't dwell on it.

The caliper is a simple tool for measuring the outer dimensions of workpieces. It consists of a pair of swivel curved legs fixed on the same axis. There is also a spring type of caliper, it is set to the required size with a screw and nut. Such a tool is a little more convenient than a simple one, because it retains the specified value.

The caliper is designed to take internal measurements. There is a regular and spring type. The device of this tool is similar to a caliper. Instrument accuracy is 0.25mm.

A caliper is a more precise device. They can measure both external and internal surfaces.processed parts. The turner, when working on a lathe, uses a caliper to measure the depth of a groove or ledge. This measuring tool consists of a shaft with graduations and jaws and a frame with a second pair of jaws. With the help of a screw, the frame is fixed on the rod in the required position. The measurement accuracy is 0.02mm.

Depth gauge - this device is designed to measure the depth of grooves and undercuts. In addition, the tool allows you to determine the correct position of the ledges along the length of the shaft. The device of this device is similar to a caliper.

Micrometers are used to accurately determine the diameter, thickness and length of the workpiece. They give readings with an accuracy of 0.01 mm. The measured object is located between the micrometer screw and the fixed heel, the adjustment is carried out by rotating the drum.

Inside gauges are used for accurate measurements of internal surfaces. There are fixed and sliding devices. These tools are rods with measuring ball ends. The distance between them corresponds to the diameter of the hole being determined. The measurement limits for the inside gauge are 54-63 mm, with an additional head, diameters up to 1500 mm can be determined.

Recommended:

Technological processes in mechanical engineering. Automated process control systems

Technological process is the basis of any production operation. It includes a set of procedures carried out in a certain sequence, the action of which is aimed at changing the shape, size and properties of the manufactured product. The main examples of technological processes are mechanical, thermal, compression processing, as well as assembly, packaging, pressure treatment and much more

Volsky Mechanical Plant: history and contacts

There is a city of Volsk in the Saratov region. Here is the largest mechanical plant specializing in the repair and production of ATGM combat vehicles, which stands for anti-tank missile systems. This article will consider the history of the creation of the Volsk Mechanical Plant, the activities and contacts of the enterprise

Types of threads used in mechanical engineering

A thread is an ornate spiral with a constant pitch applied to a conical or cylindrical surface. It is the main element for connecting two types of fasteners. To date, for general machine-building applications, the main external and internal threads are metric

Technology of mechanical engineering: information about the speci alty

Engineering technology is a speci alty that remains in demand: every year at least 4 people apply for one budgetary place

Irkutsk heavy engineering plant: history and date of establishment, address, management, technical focus, stages of development, introduction of modern technologies and quality

Irkutsk heavy engineering plant is a city-forming enterprise producing equipment for leading industries in Russia. The company's products are supplied to the domestic market, finds recognition and demand abroad