2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:31

Timing of working time helps to correctly monitor and take into account working time. An example of the use of these records can be found in almost every factory or enterprise where you need to normalize the working day. Timekeeping with timekeeping is a way to study the time spent on performing an action. At the same time, measurements imply a description of the technological process, working conditions, production methods.

Measurements will help to fix working hours

Timekeeping as a way of studying working time depends on the conditions of its implementation and the goals for which it is done. For example, the requirements for timekeeping, which will be used to calculate wages and the price of services, differ from those that must be observed when compiling timekeeping to determine the level of workload of staff.

Correct measurement of time spent on work helps to draw up the correct schedule for recording working time, as well as bring it to full loadidle capacities of both manpower and used equipment.

Who should deal with normalization and measurements?

Usually this is done by professional raters who are trained at the enterprises. A well-trained and experienced rationing officer is an indispensable employee who helps management control staff working hours, as well as properly distribute the workload.

Where to start?

First of all, determine the purpose of the timing. For example, you need it in order to draw up a schedule for recording the working time of an employee whose remuneration does not depend on output, but is made simply at an hourly rate.

Remember that such personnel are not interested in working faster. There is no incentive to work more efficiently, since the level of wages does not directly depend on this. Therefore, the performance of such employees will depend on the quality of the timing.

If we talk about large enterprises, then work orders are made for the working staff, which indicates the list of work that the employee must perform. Study it carefully, look at the types of work that will be carried out. If you do not have an understanding about a particular type of work, you need to find a flow chart for such a workflow. Basically, each enterprise has either a technical department or a production department that deals with this. You can contact them with a request for the preparation of a technological map, as well asconsult on the work to be carried out.

After we have decided on the list of works and the order of their completion, it is necessary to draw up a description of the work processes that will be measured. Make up the criteria that you need to focus on when measuring: determine the start point of the process and the point at which the process will end, the use of working time, the cyclical work, as well as other nuances.

After collecting all the necessary theoretical information, start measuring. You will need pre-prepared timekeeping forms, or you can keep notes in a draft (it is more convenient to make comments on the records).

The normalization commission should observe

More than one person needs to record working hours - examples of such fixing will not be completely objective, since an employee, being without additional control, can delay the work process. It is recommended to measure time with the participation of representatives of the technical management (production department). They will control the correctness and sequence of work. It is also recommended to invite representatives of the management of the service whose employee is measuring the use of working time. Believe me, when he sees such a commission, he will immediately work much more productively, and he will be less tempted to try to outsmart you.

When taking measurements, you need to be careful. There are works that are carried out in a cycle. And there are those that are made onlyonce. In works that are done in a cycle (for example, cutting pipes), not all work can be taken into account for each such cycle. Preparation of the workplace, setting up the machine and other equipment, installing cutters - after measurements, all these works will need to be evenly divided into each part that was produced.

Workflow cycles

Then you need to correctly fill out the form with measurements. In order to do this, you can use the following example of filling in the timing of working hours. It is not difficult to compile it if you understand the basic principles of measurements. At the same time, the process should be divided into periods of working time: operational, maintenance of the production process, preparatory and final stage, and it is also worth considering the time for rest and own needs.

Operational time of work - the period of time that it took the worker to complete the tasks. This paragraph takes into account the period of time that would be required by the worker if he did not leave the workplace, was not distracted, and all the equipment would be in one place and already in working mode.

Time for maintenance of the production process consists of the time spent on auxiliary work, which is necessary so that the production process does not stop. For example, replace equipment that is worn out, change a damaged drill, change machine oil, etc.

The preparatory and final stage includes preparatory operations, setting up devices and other work to prepare the workplace. CorrectlyThe following example of filling in the timing of working hours will help you write down all the values.

After detailed analysis of measurement records, you will find jobs that are not included in the workflow flow chart. Also, they cannot be attributed to the listed types of costs.

What is not related to the process of performing work should be excluded. These are mainly moments such as: talking on a mobile phone, performing related work, performing urgent instructions from management and other actions not related to the performance of the measured work.

How to fill out the form correctly?

In order to display the measurements in a grammatical way, it is necessary to issue a timing of the working time. The form and an example of filling it out are given below.

| Work Code | Workflow name | Name and sequence number of timing | Average | ||||

| 12.01.15 | 13.01.15 | 13.01.15 | 13.01.15 | 14.01.15 | |||

| 1 | 2 | 3 | 4 | 5 | |||

| Duration, s | |||||||

| 1 | Get a task from the master | 40 | 15 | 15 | 15 | 38 | 24, 6 |

| 2 | Bring a pipe from the warehouse | 61 | 24 | 24 | 24 | 55 | 37, 6 |

| 3 | Prepare the workplace | 65 | 21 | 21 | 21 | 74 | 40, 4 |

| 4 | Set up the machine | 41 | 17 | 17 | 17 | 60 | 30, 4 |

| 5 | Prepare machine for cutting | 20 | 9 | 9 | 9 | 25 | 14, 4 |

| 6 | Cut pipe | 25 | 15 | 17 | 21 | 17 | 19, 0 |

| 7 | Put the blanks in place | 10 | 12 | 10 | 11 | 12 | 11, 0 |

| 8 | Clean the machine and clean up the workbench | 35 | 10 | 10 | 10 | 27 | 18, 4 |

| 9 | Submit work to master | 40 | 17 | 17 | 17 | 30 | 24, 2 |

| Total | seconds | 337, 0 | 140, 0 | 140, 0 | 145, 0 | 338, 0 | 220, 0 |

As the sample of filling in the timekeeping of working hours shows, the type of pipe cutting work was measured. Three measurements were taken on the same day. Since they were produced in a row, the worker did not spend time on each part to receive a task from the master, go to the warehouse for pipes, prepare the workplace, etc. Therefore, the time spent on the first part for these types of work is divided into two others metering.

Need to display average man-hours

After the measurements are made, the average value is displayed. According to the data that this example of filling in the timing of working hours shows, the average duration of such work is 220 seconds. Converted to hours, you get 0.061 people/hours.

When scheduling the working day, you can use this data. For example, if you want to 100% load an employee with this work, then you can calculate how much he should cut pipes. Given that the working day consists of eight hours, then:

8: 0, 061=131, 15 pieces

It turns out that the worker has to cut pipes about 131 times.

Consider all factors when doing the job

This is a straightforward calculation and approach to measuring working time. But when planning a work schedule for an employee, other factors must be taken into account. A person simply physically cannot, like a robot, stand at the machine 8 hours a day. He will be absent for personal needs, rest, from which the timing of working time may be distorted. An example is the following: for complex work behind the machine, you need at least 5 minutes of rest after each hour of work.

Also, the skill of an employee plays a significant role. It is necessary to take measurements from several workers in order to derive a real average value. You can not focus on the results of one "experimental". If we talk about locksmiths, turners, repairmen, then the following pattern is often observed: the higher his discharge, the faster they do the work. The experience of the employee also plays an important role.

Other temporary losses

There are various losses of working time. For example, a locksmith can cut records, and someone from another service will come to him and ask for some tools or help to do some urgent work that cannot be postponed.

Usually such losses are difficult to describe. It is best to derive the wastage factor and multiply it by the time norm, thereby giving employees the opportunity to take a breath while working.

For example, at enterprises that produce parts in workshops, rationing allow 8-10% loss of time when rationing the working day and take them into account in the schedule.

Also, before filling out the final timing, it is recommended to read all the footnotes in the already approved standard time standards - usually they describe the nuances that need to be taken into account, and describe the features of the rationing of a particular work.

Recommended:

Inventory sheet: form and sample filling

Control of the presence of assets in the enterprise is carried out during the inventory. Goods, cash, stocks and other fixed assets can be the objects of verification. The inventory sheet reflects the results of the audit. Enterprises use the unified form INV-26

Working hours. Photo of working time: example, sample

Efficiency makes people successful, competitive. A great tool for researching how efficiently you use working time is working time photography, in other words it is also called timekeeping. What is this tool, how to use it and what results it brings - read in the article

Symbols in the time sheet. How to fill out a time sheet (sample)

Working time and its accounting are important components of any organization, allowing you to control the activities of the company and discipline employees. In order to simplify this procedure, a special form was developed - a time sheet

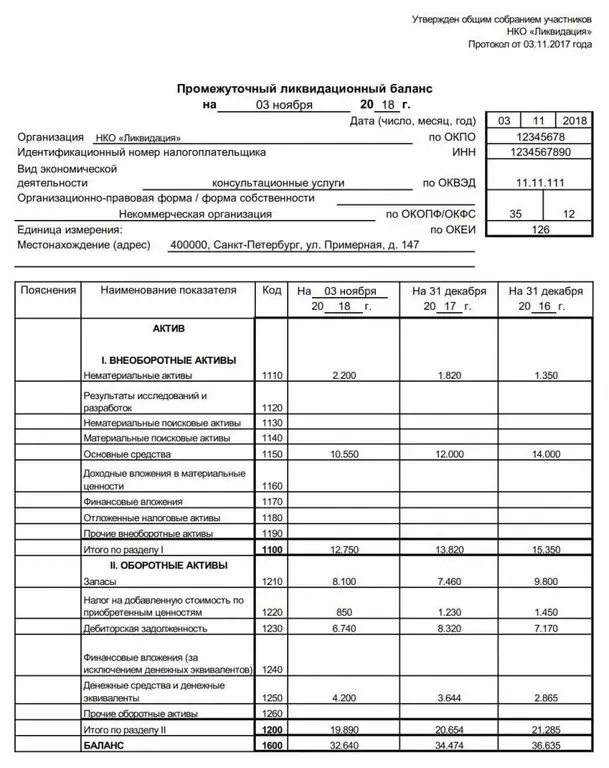

Liquidation balance sheet is Definition of the concept, approval, form and sample of filling out the liquidation balance sheet

The liquidation balance sheet is an important financial act drawn up during the closing of an organization. It can be intermediate or final. The article tells what is the purpose of these documents, what information is entered into them, as well as how and when they are approved and submitted to the Federal Tax Service

Accounting for working hours in the summary accounting. Summarized accounting of the working time of drivers with a shift schedule. Overtime hours with summarized accounting of wor

The Labor Code provides for work with a summarized accounting of working hours. In practice, not all enterprises use this assumption. As a rule, this is due to certain difficulties in the calculation