2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:32

Greases are one of the essential elements in today's industry. They are used for machining chassis, chains, rotary axles in machinery, for valves and many other applications.

Their use is especially effective in conditions characterized by sudden temperature changes and high humidity.

Features and properties of greases

These funds have plasticity. This is the main difference between them and liquid lubricants. They are produced on the basis of oils with the addition of thickeners, which can be used as polymers, clay, carboxylic s alts.

- Greases have different colors. They are transparent, black, light brown.

- Many of these products provide corrosion protection for machined parts.

- Distinguished by the lack of smell.

- Do not change their density with temperature changes.

- These lubricants do not run, which makes them convenient to use.

- Minimum turnaround time varies from 2 to 4 weeks. Then the agent must be replaced.

Greases:species

Today, there are a huge variety of greases. Let's talk about the main ones.

- Sodium. They are often supplemented with calcium. Another name is constants. It is advisable to use them in conditions with temperatures from 70 to 110 degrees. The downside is the fact that they are afraid of water and can dissolve in it.

- Lithium. Made with lithium. They are especially effective in conditions where there is strong vibration, under heavy loads. Great for long term use.

- Aluminum. Made from aluminium. Resistant to moisture, prevent oxidation of metals, thereby increasing conductivity. Often used in conditions characterized by elevated temperatures.

- Polyurethane. Produced on the basis of powder. They are prone to biodegradation. Do not have any harmful effects on the environment and the human body.

- Teflon. They are distinguished by good heat resistance, they can withstand temperatures up to 250 degrees. A kind of film is left on the processed parts, which has electrical insulating and water-repellent properties.

- Polyglycol. Their use allows you to extend the life of the mechanisms. Especially used in high temperature environments.

- Silicone. Protect against corrosion. Forms a film with water-repellent properties. Improve sliding, thereby preventing friction of parts. Will not wash off with water.

In addition to these main types, there are many others: pastes, greases based on thickeners (both organic and inorganic), etc..

Product Applications

Greases have a fairly wide range of uses. So, for example, silicone is used for refrigerators. They are food approved. Such lubricants are common in everyday life. They process the paintwork of the car body, lubricate the locks and door hinges.

Konstalins are used for all types of transmission mechanisms - shafts and rollers. In addition, they are a good solvent for varnishes.

Lithium grease is often used for exposed parts of equipment. It is excellent for plain bearings and roller bearings.

As you can see, greases have a range of useful properties that protect mechanical parts during production.

Recommended:

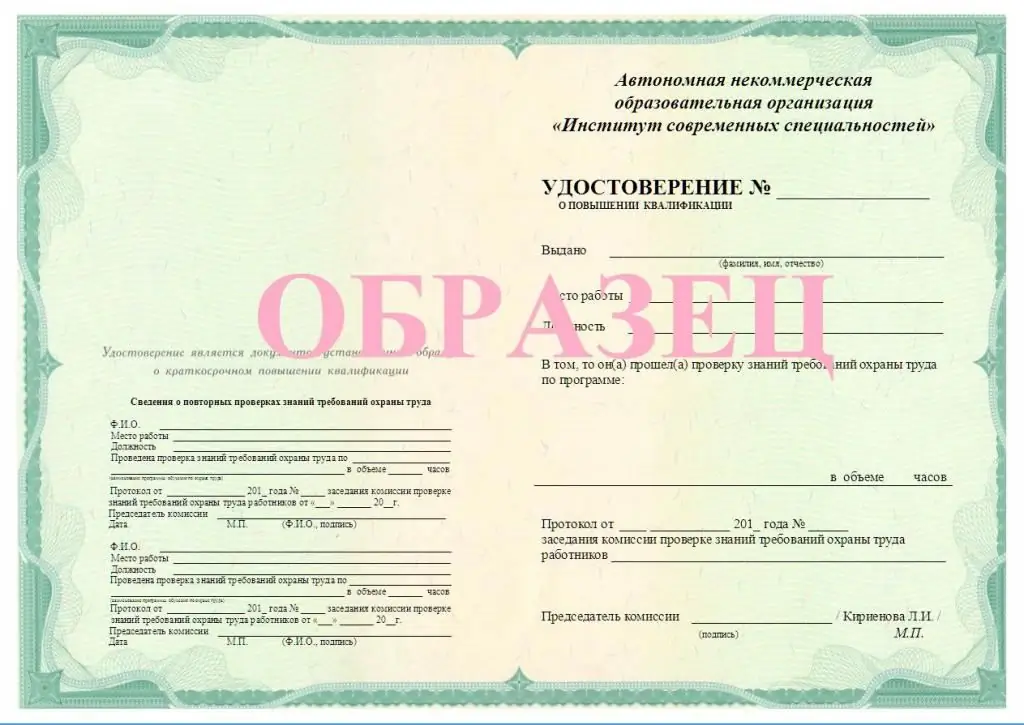

Professional development in labor protection: features, requirements and recommendations

There is a labor protection engineer in every production. This person is obliged to create comfortable working conditions, as well as to check compliance with safety regulations. And this means that qualifications need to be constantly upgraded

Greases are Concept, range, composition and application

Grease is one of the main components that effectively affects the safe and long-term operation of both simple and complex mechanisms with rubbing surfaces. Requirements for greases. Operating principle. Advantages and disadvantages. Basic characteristics and properties of lubricants. Classification and labeling

What are the best lithium greases? Features, benefits, application examples

The modern lubricants market is a wide range of various products, however, most motorists most often use lithium greases. This is due to the fact that such compositions are versatile and can be used in different areas

Welder's mask is a reliable means of protection against the most harmful factors of the welding process

Of course, metal welding is one of the most dangerous for humans, because all welding work is accompanied by a constant release of harmful substances and factors. Some of the most dangerous are: electric arc, bright glow, toxic gases, infrared and ultraviolet radiation

Instruction on labor protection for an engineer on labor protection, equipment operation

Almost every large enterprise has a labor protection specialist. The essence of his work is to maintain safety standards in the organization. No less important is the presence of a special document called "Labor Protection". All these things will be discussed further