2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:35

The auxiliary power unit (APU) is most often used to start the main engine. This equipment is often used in aviation technology. However, it can also be used on armored vehicles, ships, locomotives and cars.

Main characteristics of the APU

For such a power plant with air extraction after the compressor, its flow rate, pressure of this air, and also its temperature are the main parameters. However, it is worth noting here that such a characteristic as air pressure is not an energy indicator. In other words, it cannot be used as an assessment of the resource indicators of an auxiliary power unit of the APU. It will also not be possible to evaluate the workflow with its help. For this reason, it is necessary to resort to the use of such a conditional parameter as equivalent air power. In addition, the parameter called specific fuel consumption is also important. For a power plant with air extraction after the compressor, it meansfuel consumption per hour per 1 kW of equivalent air power. In addition to these main characteristics, there are also minor ones:

- compressor stability margin;

- excess air ratio in the combustion chamber;

- temperature and pressure of the working fluid;

- coefficient of performance (COP) of a compressor, turbine, etc.

Short description of APU for car and locomotive

If we talk about locomotives, then rarely, but still, gas turbine locomotives are used. On such vehicles, an auxiliary power unit is mounted in order to start the main engine. In addition, with its help, the production of maneuvers and movement of a single locomotive is carried out.

If on a car with special equipment that requires electrical power and an idle engine, fairly well-known electrical units were used as APUs. It is also worth noting that on a number of special vehicles it was also possible to start the main engine.

Aircraft APU device

As for the aircraft auxiliary power unit, it is a source of hot compressed air, as well as DC and AC electrical energy that can be used to power aircraft systems.

When the aircraft is on the ground, the APU can be fully used in order to ensure complete autonomy of the transport. This is usedautonomy in the process of pre-flight preparation. Such a system can only be operated at those airfields located at an altitude of no more than 3 km. It is also worth mentioning that an auxiliary power unit with 300 m or another model can be used to take both compressed air and electricity at the same time. Compressed air enters the aircraft's air conditioning system, and electricity is used to start the main engine. The APU is well suited for starting a gas turbine engine, its mounting system, air intake, exhaust system, as well as a system that provides engine starting and control.

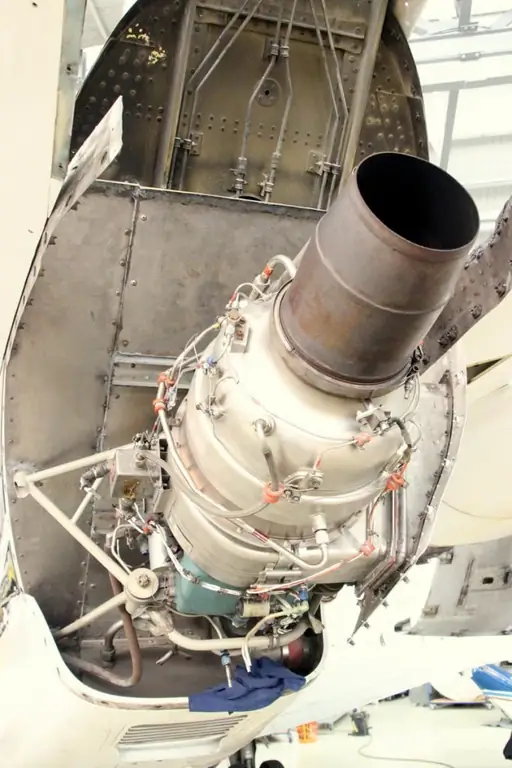

Design of the APU compartment

The system is equipped with a drainage system. At the lowest point there is a device called a drainage collector. There is also a branch pipe, which is designed to bring the liquid out, by gravity. The gas turbine engine of the aircraft is also located in the APU compartment, which is located in the tail non-hermetic part of the fuselage. On the flight engineer's console there is a panel "Launching the APU". This panel contains all controls and controls for the auxiliary power unit.

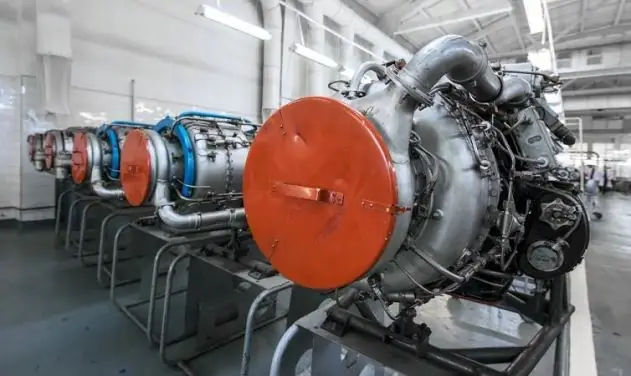

APU TA-6A

This type of auxiliary installation, like TA-6A, is most often installed on board such aircraft as TU-154, IL-62M, IL-76, TU-144, IL-86M, TU-22M. It can also be installed on some ground transport units. The main purpose is to supply compressed air to start the main engines of the aircraft on the ground to supply compressed air to the air conditioning system.

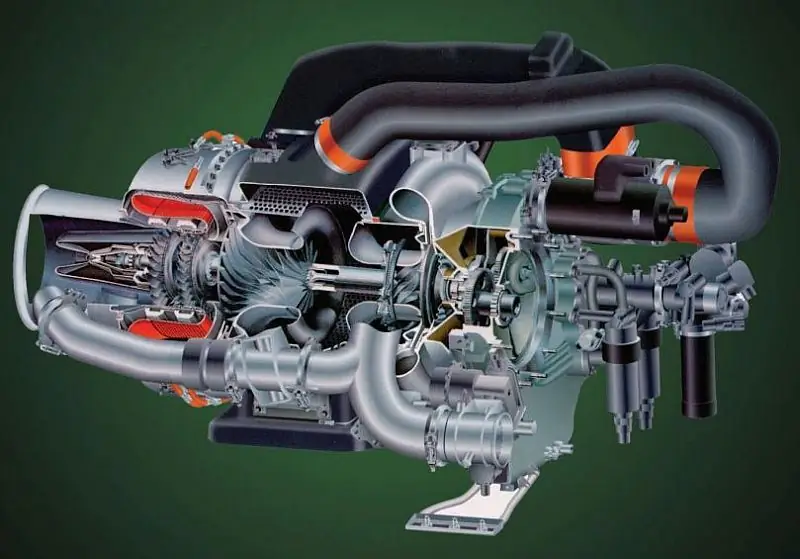

It is important to note here that this APU can be used to power the on-board electrical network with both AC and DC on the ground and, most importantly, can be used for the same purpose in flight if the main system fails. The unit itself is presented in the form of a single-shaft gas turbine engine with air extraction behind the compressor. This suggests that the main characteristics of the TA-6A auxiliary power unit are the flow rate, pressure and temperature of the bleed air. This device consists of several main elements. The first main assembly includes a gearbox with a starter-generator. There is also an alternator, as well as several other attachments. All of them are necessary in order to ensure the normal operation of the engine. A three-stage diagonal-axial element is used as a compressor.

Indicators of the Armed Forces of Ukraine TA-6A

The device has the following main specifications:

- The direction of rotation of the rotor from the side of the nozzle is right.

- The second important parameter is the rotor speed for the turbocharger. While debugging the engine at idle, the temperature range should be around 60 degrees Celsius. As a percentage, the indicator should be 99 ± 0.5%. If we talk about revolutions per minute, then the indicator should be in the region23950±48.

- As for the main mode of operation, the change in the rotor speed is allowed in the range from 97 to 101%.

- There is such a parameter as vibration overload of the engine. At the beginning of the service life, this coefficient should be 4.5. At the end of the service life, it can increase to a maximum of 6.0.

- There is such a parameter as the duration of the cold load cycle. The maximum value is limited to 32 seconds.

- During cold load, rotor speed should be between 19% and 23% of maximum power.

Engine operation TA-6A

During the operation of the auxiliary power unit, atmospheric air will be sucked in by the compressor through the grid and the radial-circular inlet. The compressor has three stages, after passing through which the air is compressed and fed into the gas collector casing. From here, the bulk of the selected substance enters the combustion chamber. The rest can be passed into the exhaust pipe volute and discharged back into the atmosphere through the exhaust pipe, or it can be supplied to the consumer.

It is worth noting that the air supplied to the combustion chamber is divided into two streams - primary and secondary. As for the primary flow, it enters the combustion zone through the evaporator tubes, as well as holes in the head of the flame tube. The same evaporator tubes also supply fuel from the starter manifold.

The secondary flow follows through a certain number of holes. After thempassing, it enters the same compartment as the substance from the first stream. In this tank, these flows are mixed with gas, which makes it possible to achieve the desired temperature regime for the entire gas flow entering directly into the turbine. It is also worth noting that there are gaps in the walls of the chamber. Through them, a small amount of air passes inside and is used there in order to cool the walls of the chamber.

Helicopter Auxiliary Power Unit

The Helicopter Accessory is somewhat different from the one mounted on board the aircraft. The main components for the device were a pair of engines, as well as a gearbox. If such a need arises, then the power of one engine will be enough to continue the flight. It is also worth noting that the right and left engines of the installation are interchangeable. However, this is subject to the fact that it is possible to turn the exhaust pipe. The engine itself includes such elements as a compressor with rotary blades, a combustion chamber, a compressor turbine and a pivot turbine, which transmits power through a spring shaft to a VR-8 gearbox. There is also an exhaust device and an accessory drive box.

Recommended:

Nuclear power plants. Nuclear power plants of Ukraine. Nuclear power plants in Russia

Modern energy needs of mankind are growing at a gigantic pace. Its consumption for lighting cities, for industrial and other needs of the national economy is increasing. Accordingly, more and more soot from burning coal and fuel oil is emitted into the atmosphere, and the greenhouse effect increases. In addition, there has been more and more talk in recent years about the introduction of electric vehicles, which will also contribute to the increase in electricity consumption

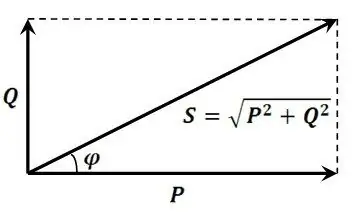

What is reactive power? Reactive power compensation. Reactive power calculation

In real production conditions, reactive power of an inductive nature prevails. The enterprises install not one electric meter, but two, one of which is active. And for the overexpenditure of energy “chased” in vain through power lines, the relevant authorities are mercilessly fined

Product manufacturability indicators: types of indicators and evaluation methods

Product manufacturability indicators are the most important component of assessing the quality characteristics of products, designs, parts, and so on. They make it possible to compile a comprehensive description of the effectiveness of technological products in relation to the adaptability of the design to its application in specific conditions, for example, in production

Good Forex indicators. The best Forex trend indicators

Forex indicator is an important currency market analysis tool that helps traders make optimal trading decisions

The most accurate indicators for MT4: rating. The best indicators for MT4

Are you a trader? Do you need the best indicators for MT4? We will talk about them in the article. In Forex trading, traders use an impressive number of various indicators with which they can accurately enter the market