2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:30

There are several stainless steel processing modes that help not only improve its quality characteristics, but also significantly improve its appearance. In addition, the processing of such a metal surface allows you to bring performance indicators to the desired indicators.

Material grinding

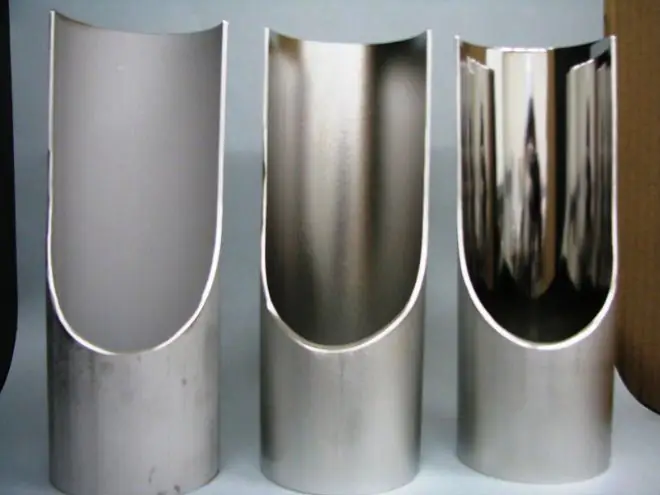

Due to the different ways of processing stainless steel, it is often used not only for the manufacture of parts or structural elements, but also for decoration. In order to improve the appearance, as well as to achieve the required level of roughness of the coating, a method such as grinding and polishing is used. Quite often, these two methods are combined into one, and it is called sativation. This processing method got its name due to the fact that the surface of such steel, after completion of work, begins to resemble satin or satin fabric.

Processing of stainless steel welds, for example, begins with the fact that it is necessary to bring the surface down to small scratches. For this, a grinder with a circle of petal type is used.

Why sanding

In addition to helping improve the appearance of the metal, sanding can also help eliminate surface imperfections. If you cannot completely eliminate them, then using this method you can make them almost invisible. As for the execution methods, the operation can be performed both manually and with the help of special equipment that operates from an electric or pneumatic drive. There are some of the most common devices that are used to implement this method of processing stainless steel:

- pneumatic band file;

- drum belt sander;

- other devices that can use sanding belt.

As for performing such an operation at home, the manual method is most often used here. To do this, they usually use either grinding sheets or devices that are called grinding. In industrial plants, of course, satification is carried out using a variety of special equipment.

It is worth adding that the processing of stainless steel seams, sheets and other things begins with the fact that a grinding wheel with a grit of 180 is used. After that, two more circles must be used - 320 and 600. To complete the work, it is necessary to process the alloy also with felt around.

Performing manual processing

Bin the event that the processing of stainless steel after welding is carried out manually, then it is necessary to adhere to the following sequence of work:

- Because the surface has been welded before, the burns must be removed first.

- The surface part of the stainless alloy, which will be the first to be subjected to such processing, must be separated with aluminum tape. It fits in 2 or 3 layers.

- The part that is not sealed with such a tape must be processed using reciprocating motions. However, you need to remember that you don’t need to press too hard on the sanding.

- After the required surface quality is achieved, the aluminum tape is re-glued to the area that was processed before, and the freed coating is polished.

Grinding on machines

It is worth noting that stainless steel turning is possible. That is, grinding can be performed on turning equipment. In this case, special grinding wheels are installed on such devices. It is also worth noting that this operation can be performed on the machine both in production and at home, if such a unit is available. It is important to note here that even the simplest turning equipment will allow you to effectively perform such an operation.

As for the operation in manual mode, it is not always advisable to use a grinder, and therefore grinding sheets are sometimes used. In that case, veryit is important to choose the right grain size. In order not to be mistaken, they usually use draft parts for selection.

Etching description

Another effective way to process stainless steel after welding is pickling. This technological operation will make it possible to cope with surface defects that arise precisely due to welding, due to the heat treatment of the alloy, due to metal processing by the plastic deformation method. Another advantage of using the etching method as a treatment is the ability to get rid of the tint on the surface of the material. Also, this procedure will renew the passive protective layer of the coating, which protects the stainless steel from the adverse effects of elevated temperatures.

Performing an operation

To carry out the operation on an industrial scale, acid is used to process stainless steel or molten alkaline media. In the event that an acid medium is used for etching, the process proceeds in two successive stages. At the first stage, the alloy is treated with a sulfuric acid solution, at the second, a solution based on nitric acid is used.

In the event that an alkaline acid is used for pickling, the steel is placed in a solution of caustic soda. This solution is able to completely remove the oxide film from the metal surface without damaging its structure.

As for performing such an operation at home, the use of acidor alkaline agents excluded. For this, special pickling pastes were invented. Their peculiarity lies in the fact that they have a jelly-like consistency. It is necessary to use such pastes with extreme caution, since in addition to nitric and hydrofluoric acid, hydrochloric acid and chloride are also included in the composition, and these substances pose a threat to human he alth.

Applying paste

Etching paste can only be applied to a surface that has previously been well cleaned and degreased. To achieve the desired effect, you just need to rinse the part with warm water, and then rinse with any detergent. After applying the paste, leave it on the metal surface. The exposure time is from 10 to 60 minutes. After the required period, the paste is washed off with ordinary running water. To apply such a composition, you will have to use either an acid-resistant type brush or a special plastic spatula. It is worth adding that if the metal area is large enough, then an etching spray can be used for application, which is sprayed using jet spraying equipment. To date, there are several manufacturers of pickling pastes that are best known. These companies include SAROX TS-K 2000, Avesta BlueOne and Stain Clean (ESAB).

Several other processing methods

There are several other processing methods that are used less often, but still sometimes used. One ofsuch methods are chromium plating. The use of this processing mode allows you to achieve such qualities as:

- appearance improvement;

- improving resistance to mechanical stress;

- great increase in corrosion resistance.

The disadvantage of this method is that it can only be performed under production conditions. The operation is quite complicated, and therefore a qualified specialist is required to perform it. In addition, special consumables are also needed. For these reasons, chrome plating at home will not work.

However, in home workshops, another operation can be successfully performed, which is called bluing. It will help to give the surface an attractive appearance. This procedure can be performed in three different ways. The first method is the use of acid solutions, the second method is accompanied by the use of alkali, the last option is the use of thermal exposure.

Turning applications

Turning stainless steel is now also possible. However, there are several problems. Parameters such as tensile strength and hardness are almost the same for stainless steel and carbon steel. However, there is a big difference in the microstructure of the material, and therefore some problems arise.

For example, if the stainless steel cutting method is used, then it will first be elastically deformed, after which it can be easily processed, and then the hardening stage begins. At this stagecutting metal will only work if much more effort is applied. The difference lies in the fact that high-alloy steel, like stainless steel, undergoes all these stages much more noticeably than ordinary steel. There are several major problems that stand out with this kind of processing.

The first problem is significant work hardening. The second problem is the need to remove chips. The third problem is the wear of the working tool. There is another problem that stands out quite strongly for heat-resistant grades of stainless alloys. The problem is the high viscosity coefficient. Because of this, the chips do not crumble, but constantly twist into a long spiral.

Cutting Tools

Due to the fact that steel is capable of strong self-hardening, it is necessary to develop special types of edges for cutting tools. In addition, it is necessary to use special alloys for the manufacture of such special tools. Today there are two types of special tools.

The first type is a cutting attachment that has a chemically deposited coating. The second type has a physically deposited coating on the cutting edge of an alloy cutting tool.

Recommended:

Food stainless steel: GOST. How to identify food grade stainless steel? What is the difference between food stainless steel and technical stainless steel?

The article talks about grades of food grade stainless steel. Read how to distinguish food stainless steel from technical

Corrosion resistant steel. Steel grades: GOST. Stainless steel - price

Why metal materials break down. What are corrosion-resistant steels and alloys. Chemical composition and classification according to the type of stainless steel microstructure. Factors affecting pricing. Steel grade designation system (GOST requirements). Application area

Meat: processing. Equipment for meat and poultry processing. Production, storage and processing of meat

Information of state statistics show that the volume of meat, milk and poultry consumed by the population has significantly decreased in recent years. This is caused not only by the pricing policy of manufacturers, but also by the banal shortage of these products, the required volumes of which simply do not have time to produce. But meat, the processing of which is an extremely profitable business, is very important for human he alth

Titanium processing: initial properties of the material, difficulties and types of processing, principle of operation, techniques and recommendations of specialists

Today, people are processing a wide variety of materials. Titanium processing stands out among the most problematic types of work. The metal has excellent qualities, but because of them, most of the problems arise

440 steel - stainless steel. Steel 440: characteristics

Many people know 440 steel. It has established itself as a reliable, anti-corrosion, time-tested hard material, which is most often used for the manufacture of knives for various purposes. What is the secret of this alloy? What are its chemical, physical characteristics and applications?