2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:30

Chemical production is one of the main sources of human benefits. After all, almost everything, from household items to clothing, is made and made on the basis of this science.

A special role is assigned to various chemical fibers that are used in numerous branches of science, technology and industry.

Classification of chemical fibers

All chemical fibers can be divided into two large groups.

- Artificial - these are those based on a natural polymer, but the processing and formation of the threads themselves takes place with the participation of physical and chemical methods.

- Synthetic - fibers that are created directly in the laboratory (industrial) conditions. They are built on the basis of ordinary low molecular weight compounds converted into macromolecules as a result of polymerization reactions.

In turn, artificial and synthetic fibers also have their own classification and examples. Consider this for synthetic samples.

They can be divided into two large groups. It is based on the structure of the carbon chain and how bonds are formed.

- Syntheticcarbon chain fibers. The main chain is built strictly from carbon atoms interconnected by conventional sigma-type bonds. A fairly large number of samples can be attributed to this group. For example, polyacrylonitrile, polyethylene, polyvinyl chloride, polypropylene, polyvinyl alcohol.

- Synthetic heterochain fibers. They differ in heteroatoms included in carbon macrochains - nitrogen, sulfur, phosphorus and others. This group includes such fibers: polyester, polyurethane, polyamide.

If we talk about the application specifically in the textile industry, then the meaning of the described representatives varies. So, artificial fibers are much more applicable for sewing clothes, bed linen, towels and other household linen items. Although there are exceptions when such a canvas finds application in technology.

Synthetic chemical fibers, on the contrary, are much more relevant in construction, technology, industry than in everyday life. Let's take a closer look at polyester threads, fabrics from them and applications.

Polyester fibers: general characteristics

From a chemical point of view, this product is the result of the interaction of terephthalic acid C8H6O4and ethylene glycol, dihydric alcohol C2H6O2. As a result of a complex polymerization reaction, transparent or white crystals are formed, which have an important property - viscosity. To do this, heat them up. It is on this feature that the production of fibers directly from thissubstances.

The melting point of such materials is above 260 0C. This makes them very convenient to use for technical purposes. There are a number of other special properties that such fibers have.

- Polyester synthetic threads are able to withstand solutions of acids, alkalis.

- Completely insoluble in water, organic solvents.

- They are dielectrics, that is, they practically do not conduct electricity.

- Products made from them are strong, very wear-resistant and reliable.

Being completely synthetic in nature, these yarns are superior in technical and textile characteristics to many artificial fibers.

Production method

According to the previous description, the production of polyester should be based on terephthalic acid. However, its physical properties are somewhat inconvenient for a harmonious and fast polymerization reaction with ethylene glycol, therefore, it is not used in its pure form, but an ester. Its name is dimethyl terephthalic ester of the same acid, abbreviated as DMT.

Therefore, the production of polyester fiber consists of several successive chemical steps:

- oxidation of a mixture of esters and paraxylene, i.e. preparation of starting materials;

- esterification, that is, obtaining a DMT ester;

- distillation and purification of the resulting product;

- recrystallization of DMT to obtain pure raw materials.

The substance prepared according to this scheme is ready to enter the next cycle of transformations, the result of which will be polyester (polyester). This takes place in two main stages.

- Transesterification of the resulting DMT with ethylene glycol. The result is diglycol and low molecular weight polyesters.

- Polycondensation of the products obtained in the first stage with each other. The result is a viscous polyethylene terephthalate.

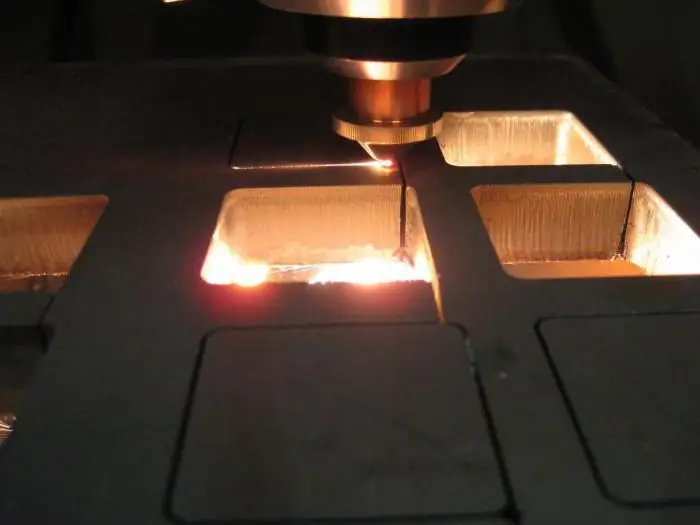

Now it's up to the technical side. The substance is passed through special small dies, as if squeezing, and thereby fibers are obtained. On cooling, they crystallize. Further processing consists of stretching, cleaning and coloring.

Material names

Similar fibers are produced and used in different countries. Polyester synthetic threads in each state got their own name, so they have many synonyms. Consider what they are.

- In Russia - polyester, polyester, lavsan.

- In America - Dacron.

- UK - terylene.

- Japan - tetheron.

- France - Tergal.

However, whatever you call them, the properties remain the same and the scope too.

Material polyester: properties

The main positive aspects of lavsan include such qualities as:

- poor wrinkle;

- flammability;

- light fastness;

- wear resistant;

- strength and softness, smoothness;

- resilience to actionmost organic solvents, as well as acids and alkalis;

- lack of abrasion;

- fabric does not support the development of living microorganisms (fungi, mites, bacteria, etc.);

- impact resistance;

- stretch resistance.

Of course, such a set of positive characteristics cannot go unnoticed. That is why the areas of application of polyester products are very wide, covering most sectors of the national economy.

However, there are also disadvantages. These include the following points:

- are difficult to dye, so juicy and bright colors are not found in such fabrics;

- are strongly electrified, since the dielectrics themselves;

- if you take a true polyester, not treated with special methods, it will be quite a tough material.

All of the listed shortcomings are easily eliminated by adding certain substances in the process of fiber production. Therefore, they are of no significant importance.

Hollow fibers

This type of polyester thread is very important in construction and engineering and is used there. Although there are exceptions. For example, such as holofiber, which has found a home in the textile industry.

Hollow fibers are used to make:

- fiberglass;

- building materials;

- heat-insulating things;

- radio products.

They are also used as filters in wastewater treatment. Hollofiber, due to its characteristics, has long beendisplaced natural feathers and down from the textile industry. It has become the main type of filling for pillows, blankets, outerwear and other things.

Ball Siliconized Fibers

This is the staple for making the softest, most environmentally friendly and allergy-free bedding. It is these fibers that are used as fillers for blankets and pillows.

Why are they used? This is due to the excellent technical characteristics.

- Do not absorb moisture.

- Elastic and elastic.

- Machine washable, easy to care for and use.

- No odor.

- Does not cause allergies.

- Microorganism growth is impossible in them.

All this gives ball siliconized fiber as a filler in furniture, bedding and clothes a clear advantage over natural natural "colleagues": down, feather.

The disadvantages include a shorter service life compared to natural materials. However, the cost of such products is much lower.

Staple fiber

Among polyester fibers, a special place is occupied by such a variety as staple threads. It is their synthetic fiber plant that produces more than all the others. This is due to the fact that such a product goes directly to the manufacture of yarn, and then the material for sewing clothes, textiles, and so on.

Staple fiber is often called a fiber formed froma harmonious combination of wool or cotton with polyester. This symbiosis makes it possible to obtain the following types of materials:

- costume;

- coat;

- tulle;

- shirt;

- curtain;

- pay;

- felt;

- carpet;

- fur.

Obviously, what kind of products can be sewn and made from such components.

Polyester technical thread

These fibers are used to make the following products:

- fishing nets and trawls;

- ropes and ropes;

- hoses for refined products;

- canvas;

- conveyor belt;

- seat belts and drive belts;

- tire cord;

- thermal insulation and filter materials.

The hollow fiber discussed above can also be attributed to such threads.

Products made of polyester materials

What other products can be made from polyester? The special significance of such materials which are used as fillers has already been described above. I just want to add that holofiber allows you to get the softest and most comfortable pillow and a warm and light blanket. Polyester fiber in the textile business is simply irreplaceable and every year it rises higher and higher in its value.

Also use lavsan to obtain the following types of fabrics:

- taffeta;

- crepe;

- knitwear;

- crimplen;

- melan.

They are used to make clothes, tulle and curtains, stage attributes, etc.

Another type of practical human activity in which polyesters are used is surgery. Medicine has considered the possibility of making artificial blood vessels and surgical sutures from polyester. This naturally facilitates many life-saving operations.

Reviews on products and this fiber

Given that, in addition to the positive characteristics, materials based on polyester still have disadvantages, not all people are satisfied with the products. When it comes to building applications, there can be no dispute here: lavsan is the leader. However, when talking about textiles and clothing, there are also differences. Negative opinions are also steadily received by polyester fiber. Reviews of this kind are based on the shortcomings of the fabric itself - electrification and limited service life.

However, most people tend to consider polyester one of the most comfortable, beautiful and high-quality materials of our time. Therefore, clothes, household items and bedding made from these materials only gain popularity over the years.

If you look at the reviews of polyester-based pillows and blankets, the vast majority of them will still be positive, which is completely justified and fair.

Recommended:

Modern production. The structure of modern production. Problems of modern production

Developed industry and a high level of the country's economy are key factors influencing the we alth and well-being of its population. Such a state has great economic opportunities and potential. A significant component of the economy of many countries is the production

Gas production. Gas production methods. Gas production in Russia

Natural gas is formed by mixing various gases in the earth's crust. In most cases, the depth of occurrence ranges from several hundred meters to a couple of kilometers. It is worth noting that gas can form at high temperatures and pressures. In this case, there is no access of oxygen to the place. To date, gas production has been implemented in several ways, each of which we will consider in this article. But let's talk about everything in order

Synthetic fibers. Synthetic polyamide fiber

Synthetic fibers began to be produced industrially in 1938. At the moment, there are already several dozen of them. All of them have in common that the starting material for them is low molecular weight compounds that are converted into polymers through chemical synthesis. By dissolving or melting the resulting polymers, a spinning or spinning solution is prepared. Fibers are formed from a solution or melt, and they are only then subjected to finishing

Acetate fiber. Production of acetate fiber

At all times, the textile industry has been one of the most important sectors of the national economy in our country, as it gave the state a huge amount of much-needed fabric, which was constantly required not only for the production of clothing, but even used in the production of weapons

Ytterbium fiber laser: device, principle of operation, power, production, application

Fiber lasers are compact and rugged, point precisely and dissipate thermal energy easily. They come in many forms and, having much in common with other types of optical quantum generators, have their own unique advantages