2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:35

Petroleum resources make up the bulk of the fuel supply materials for power stations, and are also widely used at filling stations, in servicing technical facilities and powering electrical equipment. This infrastructure includes storage, pumping and filtration facilities, each of which, to one degree or another, leaves raw waste that is detrimental to the environment. Accordingly, there is a need for timely disposal of petroleum products that cannot be used in industry or transport services. According to experts, the total waste in the form of oil pollution accumulated at individual facilities reaches hundreds of thousands of cubic meters in volume.

Tasks of oil waste disposal points

The main direction in the general complex of tasks for the disposal of various types of petroleum products is the cleaning of means for pumping, storing and transporting material. Only in this case it is possible to ensure the proper quality andfuel safety. As a rule, for such purposes, detergents, sedimentation tanks, sprayers and even sandblasters are used to remove stagnant traces of technical oils. The direction of liquidation of the consequences of accidents in the form of oil spills is also popular. Soil contamination with chemically hazardous substances can threaten an ecological disaster. In the process of disposal of soil contaminated with oil products, methods of intensification, biochemical purification, pyrolysis and traditional disposal at landfills are used. Now it is worth considering the current methods and technologies for the disposal of petroleum products in more detail.

Means of mechanical processing of sludge

Several recycling techniques are used in combination, including centrifugal separation, settling, hydrological processing, etc. Basically, the tasks of separating oil sludge into different fractions depending on size and density are set. More modern techniques allow automatic separation of materials and levels of toxicity. The centrifugal method, coupled with settling technologies, separates oil emulsions from the water layer.

In the future, by determining the degree of concentration of the target elements, it is possible to filter out significant proportions of impurities. Direct disposal of oil sludge is carried out at the final mechanical processing station on the lower layers of sedimentation tanks, where about 75-80% of heavy suspensions are concentrated. Hydroprocessing generally offers the same separation principles, butthe separation process is more intensive due to the desorption of petroleum products - additional technological operations are connected in the form of heating and mixing.

Biochemical disposal method

This technique is based on the principle of decomposition of microorganisms through oxidation. In practice, this method is often used in the recultivation of soils and other contaminated materials. For example, the biochemical utilization of sawdust contaminated with oil products provides for the activation of the metabolism of the natural microflora of raw materials. Different cleaning modes are used, differing in moisture indicators, the intensity of the aeration effect, the inclusion of nutrients and other parameters. At a high level of pollution, active biological substances are used that have the effect of oxidizing oil microorganisms. But the biochemical method also has a number of disadvantages, which include the risk of disturbing the natural biocenosis.

Physico-chemical disposal method

This is a broad group of methods for processing and purifying unwanted oily products, the most popular methods of which include extraction and flotation. Thus, extraction methods are based on the principles of dissolution of polar compounds against the background of thermal exposure. As a result, solid and liquid media of the target material are formed, which can be easily separated. As for the disposal of petroleum products through flotation, this technique is implemented with the support of hot air mixtures that separate the concentrates of the mainsubstances and mechanical impurities. Physical and chemical methods also include the so-called oil gathering. When performing this technique, sludge accumulators and drum separators are used. But as a regular means of disposal, this method is used infrequently. Basically, oil gathering is involved in the elimination of the consequences of accidents with oil spills on the surfaces of water bodies.

Thermal method of recycling oil products

This method is based on the process of thermal decomposition, which can be subjected to various petroleum products. Complete decomposition is considered the most effective, when two media are formed in the course of destruction - based on carbon dioxide and water. Depending on the conditions of carrying out, several types of thermal processing are distinguished:

- Incineration of sludge in kiln units where there is a fluidized bed.

- Incineration (thermal decomposition) in an oxygen-free environment.

- Pyrolysis.

The most common and somewhat universal method is the disposal of waste oil products in furnaces according to the "fluidized bed" principle. In this case, under the influence of hot air currents, recreational chambers provide mixed suspensions at the outlet.

Technologies for regeneration of petroleum products

Cutting oils based on organic and water are often used in industry and transport in the maintenance of machinery. Conventionally, machine fluids are divided into two groups -recoverable and non-renewable. In order to save consumables, cleaning and recovery technology can be used, thanks to which the oil product acquires lost performance. Technical oils of this group include anticorrosive, liquids from circulation plants, lubricant mixtures from mud storage tanks, etc. At the stage of basic collection, waste oils and petroleum products can also be disposed of, but part of the product is passed through a filter press. Further, the procedures for restoring the physical properties of the liquid are carried out by means of the action of "deaf" steam with heating up to 90 °C. The thermally processed oil is mixed with compressed air and allowed to stand for 30 minutes.

Tarr cleaning technologies

Purification of tars with sulfuric acid is used in cases where it is necessary to eliminate resinous, nitrogen- and sulfur-containing, as well as unsaturated compounds, which cause a low level of stability of the oil product during storage. Acid tars are characterized by the presence of highly viscous resinous masses, which include water, organic impurities and sulfur compounds. The cleaning process involves different means depending on the target layer. Thus, the disposal of waste oil products based on acid tars can be carried out in relation to the following levels:

- Top. Acid oily liquid. Does not require special processing and is eliminated by the main biochemical methods.

- Medium. acidic water environment. Consists of sulfuric acid and precipitation. It is subjected to chemical-thermal treatment, and in some cases it is separated and transported in shares for regeneration.

- Lower. Pasty mixtures of acid tar with concentrated sulfuric acid. To date, the best way to use bottom sediments of tar is processing into industrial bitumen.

Combined disposal methods

Universal methods of processing oil products that can be applied to materials with different physical and chemical properties. The most effective method of this kind can be called a combination of mechanical disposal with separation techniques, cleaning and physico-chemical treatment. In practice, these operations are not performed simultaneously, but in stages. The primary disposal of petroleum products in a combined way involves the separation of emulsions from sludge, followed by filtration of the water-emulsion layer, neutralization of residues and processing of the sedimentary layer.

Russian waste disposal companies

Domestic enterprises have rich experience in this area, offering a wide range of integrated services for the processing of oil waste. The leading positions in the segment are occupied by VZTU and Lukoil-VNP. Research activities are regularly carried out at their facilities, and the range of technologies aimed at solving cleaning problems is expanding. High-quality utilization of petroleum products in Moscow is provided by the Ecoinvest company, which offers the processing of machine oils, emulsions,organic matter and contaminated materials. As for the unique Russian processing facilities, we can note the Insteb equipment, which effectively utilizes and neutralizes oil-containing materials, and a wide range of sorbents - for example, Econaft and Modifier preparations deserve attention.

Problems of disposal of petroleum products

Despite the increase in the technological level of methods for the disposal of oily waste, there are still a number of economic and logistical difficulties that cause organizational problems of processing. Adds difficulties and the fact that modern technical fluids are increasingly subjected to alloying and modification by introducing various additives. This complicates the technological process of processing this kind of waste. And even new methods of regeneration with the possibility of recycling materials require the connection of considerable capacities and resources when performing restoration operations. Therefore, we can draw conclusions about the cost of disposal and processing of oil waste, not to mention the continued risks of environmental damage to the environment.

Conclusion

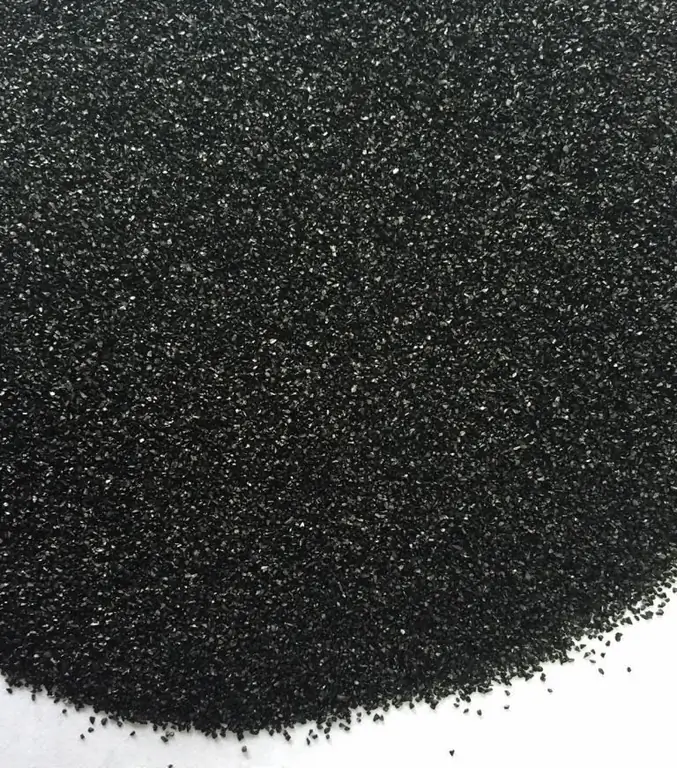

Technologists in the petrochemical industry regularly improve the efficiency of fuel and lubricant processing methods. Today, the most promising direction is the development of methods for the disposal of waste oil products through microbiological treatment with sorbents. Again, this is not cheap technology, but in areas where regularthere are pockets of pollution, they justify themselves. In addition, in some production processes with large volumes of oil used, microbiological disposal, coupled with traditional methods, also provides significant savings in the organization of processing.

Recommended:

Wastewater treatment from oil products: methods, methods and efficiency

At the moment, technologies and means, methods and units, thanks to which wastewater treatment from oil products is carried out, are among the most important means of ensuring environmental protection. In our country, for about five years now, legislatively fixed standards for the purification of liquids discharged by enterprises have been in force. Documentation on this issue establishes the quality and volume of water that can be produced by industrial facilities

Petroleum products - what is it and where are they used?

Oil (or “black gold”) is a combustible liquid fossil of biological origin. This is a kind of mixture of hydrocarbons with compounds that contain oxygen, sulfur and nitrogen

Associated petroleum gas: composition. Natural and associated petroleum gas

Oil and gas are the world's most important raw materials. Associated petroleum gas occupies a special place in the oil and gas industry. This resource has never been used before. But now the attitude towards this valuable natural resource has changed

REMIT Meat Processing Plant LLC: feedback from customers and employees, manufactured products and quality of meat products

REMIT reviews are of interest to customers who are considering options for cooperation with this company, and employees who expect to get a well-paid and stable job. In this article, we will talk about this meat processing plant, what products it produces, whether its quality corresponds to the declared one, what its employees and partners say about the enterprise

Welding of copper and its alloys: methods, technologies and equipment

Copper and its alloys are used in various sectors of the economy. This metal is in demand due to its physicochemical properties, which also complicate the processing of its structure. In particular, the welding of copper requires the creation of special conditions, although the process is based on fairly common thermal treatment technologies