2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:35

The CAM system helps to perform a number of simple transformations and calculations that were previously carried out by a programmer. Currently, the market is oversaturated with products that offer modified versions of programs for specific tasks of the manufacturer. It is enough to find the right system to meet the customer's requirements.

Why do we need updated versions of software?

CAM System stands for Automated Multi-Function Application for Easily Creating Parts Programs. With its help, you can write commands, track the execution of the resulting program, make adjustments, get information about errors and save the file in the required extension.

The new CAM system allows you to create a visualization of the resulting processing of the part. The latest applications contain fixes from previous versions, and additionally, APIs are included in the software package to help implement complex tasks. Upgraded hardware requires improved communication performance, older applications rarely have this capability.

The CAM system has found application in various industries, medicine, education, television. An employee familiar with applications may not know ISO codes, everything is complicated for himthe program will do the operation.

Varieties of programs

The difference between CAM, CAE and CAD (systems) is in their definitions. CAE stands for CAD (computer-aided design systems). But often the last term is translated as CAD systems.

CAE is a general term and includes all applications related to the computer and engineering industry. That is, any application, even the simplest graphical editor used for design, is part of an automated system. The broad concept is subdivided into branches CAD and CAM.

CAD systems are more often associated with visual models based on computer calculations. That is, the execution of accurate sketches of a future part or object that will look similar in reality after the execution of the created drawings. With their help, a number of technical errors are eliminated, shortcomings are finalized, and adjustments are made to the created appearance of the object.

CAM applications are more of a computational tool required at the modeling stage. These programs help to minimize manual labor and eliminate the human factor in errors at the time of miscalculations. Often CAD and CAM systems are combined. Then powerful computing tools are obtained to perform a whole range of activities, which reduces the cost of the final result.

In the field of creating part programs for multi-axis machining

The CAM system for CNC is aimed at eliminating the routine work of operators, adjusters and programmers whencreating control codes for machining parts. The main task of every software developer is to maintain maximum system performance while multitasking.

Modern CAM systems take up a lot of memory resources, which are not so cheap on CNC machines. And the resulting product is in demand only if it is universal and accessible to the consumer. There are not many such applications on the Internet, and often they require material costs that exceed the productivity of the machine.

There are a number of free applications that allow you to easily create long machine codes, but each software has its own advantages and disadvantages. It is difficult to understand the huge list of programs, trust arises only after viewing reviews and real examples of the work of the created codes.

Application Options and Features

As with manually entering codes from the keyboard, the application has the speed of operation and the possibility of multi-channel conversion. If CNC machines are used, CAD/CAM programs should take up a minimum of RAM and hard disk space. Since this option significantly increases the final cost of equipment upon purchase.

It is important to be able to add existing libraries. After all, why invent a hole cutting control program if there are already a huge number of ready-made templates. Similar developments have been preserved in many enterprises. Many developers are tryingreplenish your databases with ready-made solutions.

But existing patterns can also cause calculation errors or system software inconsistencies. Therefore, shells for 3D modeling are being introduced, which can be used to visually debug the program. These indicators are important in the manufacture of mass batches of products with an alternating assortment. For one-off products, buying software is not rational.

Problems solved by software

When CAD/CAM systems are used, CNC machines take on a standardized industrial look. With the help of unification, uniformity is achieved at all levels of the enterprise, which simplifies further interaction between the departments of design and technological implementation of new products. Accordingly, labor costs are reduced, time and money are saved.

One type of software on all machines allows you to use one CAM system for writing NC. Adjusters do not need retraining and mastering a huge amount of unnecessary information. Application manufacturers try to make their creations unique, which makes some products memorable from the first use. This is due to the convenience of handling the process of creating code. After all, each person may have their own preferences.

Software Ranking

Over time, there was a conditional division of the complex set of CAM systems for CNC machines. The simplest tasks of calculations and the creation of repetitive program codes occur at the lowest level. Such programs take up minimal spaceon disk use little RAM.

Medium is defined by its versatility in use in any workplace. An operator and an experienced adjuster can easily master the same working methods when creating a control program for a machine. These products have everything you need for daily production tasks.

The top level is a complex set of interdependent shells that require competent and careful handling. One miscalculation on the part of the developer, and an accident can occur. This explains the possibility of programming any model for a unique technology.

Sequence of actions when working with software

CAM systems in mechanical engineering occupy a leading place in the chain of creation of the final product. The quality of products and the integrity of the equipment depend on the competent approach of the programmer to the task. The whole process of creating control codes is strictly regulated.

The first step is to transfer the drawing from paper to the software. The main design is carried out in graphic editors that allow you to integrate transformation shells or use standard file extensions. In reality, a 3D model of the part is required, which can be created directly in CAM applications.

Next, the 3D model is converted into a machine-readable form of contours. According to the obtained points and vectors, the tool path is assigned manually according to the algorithm set by the software developer.

What is specified inprogramming process?

On the resulting model, the adjuster must select the tool binding or the zero point of the start of cutting. A place is selected for holes, grooves, the time and speed of the tool in each section are set. The cutter type or cutting head position is determined.

In addition to the parameters of the part, technological pauses are set, which are necessary for changing tools, cleaning the part from chips or for visual quality control. After a pause, a request is often made to confirm the further course of the program. Upon completion of all operations, compilation of the received commands into machine code is required.

In the process of conversion, the software issues an error notification. This is followed by the stage of debugging the program on a PC with visual control. The final step is to check directly on the machine. The first step is testing without spindle movement. Further with the revolutions of the main node. Proof of correct programming is a good finished part.

Existing products from Siemens

For programming machines based on the Siemens controller, there are software environments built into the CNC software. Examples of a CAM system that stands out for its simplicity and clarity are ShopMill and ShopTurn. The first application is intended for machining milled parts in production. Inside the shell there is the possibility of measuring the finished part, and 5 axes are supported during programming. Details are shown in 2D.

SHopTurn is used inturning design in production. Both applications occupy a minimum of RAM memory (no more than 256 kilobytes). However, there is a limitation for turning: codes can only be written to work on one caliper. Applications are built into the machine system and are able to access the hard disk, take data from the network environment of the equipment.

For Fanuc equipment

This is HW-DPRO T&TM Manual offline programming application, also suitable for ProENGINEER. ESPRIT software has similar capabilities. The latter is a powerful and high-performance program that allows you to provide the user with a realistic processing simulation. The application has technical support for all available questions.

SolidWorks is suitable for complex design of solid models. It is a whole complex of shells for all stages of designing models and creating control programs for machine tools. Supports unified documentation creation systems in Russia. There are plugin libraries for standard models.

For other controllers

HMI Embedded is used to implement complex part models. Used for both turning and milling. The resulting model is presented in 2D format. An additional option is a different kind of processing.

Helix supports 2D and 3D design, not only for CNC machine tools, but also for solution in the design of automated lines, construction in the creation of wireframe solid objects.

Recommended:

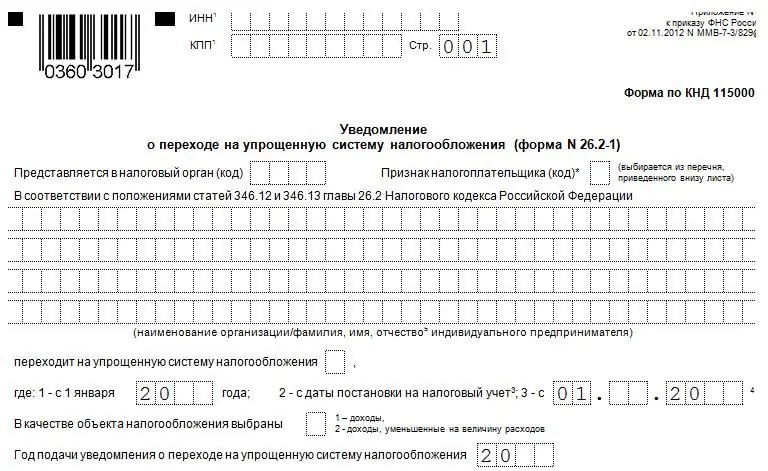

Using the simplified tax system: system features, application procedure

This article explores the characteristics of the most popular taxation system - simplified. The advantages and disadvantages of the system, conditions of application, transition and cancellation are presented. Different rates are considered for different objects of taxation

Staffing of the personnel management system. Information, technical and legal support of the personnel management system

Since each company determines the number of employees independently, deciding what requirements for personnel it needs and what qualifications it should have, there is no exact and clear calculation

Centralized management: system, structure and functions. Principles of the management model, pros and cons of the system

Which management model is better - centralized or decentralized? If someone in response points to one of them, he is poorly versed in management. Because there are no bad and good models in management. It all depends on the context and its competent analysis, which allows you to choose the best way to manage the company here and now. Centralized management is a great example of this

Deposit insurance system: system participants, bank register and development in Russia

The problem of ensuring the safety of cash deposits in banks is one of the main ones for the positive development of the country's economy. In order to ensure the stable functioning of the banking sector in Russia, a system of deposit insurance has been developed

Anti-aircraft missile system. Anti-aircraft missile system "Igla". Anti-aircraft missile system "Osa"

The need to create specialized anti-aircraft missile systems was ripe during the Second World War, but scientists and gunsmiths from different countries began to approach the issue in detail only in the 50s. The fact is that until then there simply were no means of controlling interceptor missiles