2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-06-01 07:12:56

Milling is a surface treatment method based on the alternate operation of the teeth of the cutter. There is a huge variety of tools depending on their functional purpose, processed materials, characteristics of manufactured parts.

Process Features

The milling process, like all existing methods of processing materials by cutting, is based on the main and auxiliary movements. The first is the rotation of the tool, and the second is its feed into the working stroke.

Surface milling is usually done in several successive steps:

- Roughing - the initial removal of bulk chips in order to form the required general profile, has a low accuracy class. Machining allowance (thickness of the layer to be removed, taking into account all additional factors) can be from 3 to 7 mm, depending on the material of the workpiece.

- Semi-finishing - the second stage of cleaning the intended milling object, the chips are smaller, the accuracy of the work increases and reaches the 4-6th grade.

- Fine - meticulous finish ensures high qualitysurfaces and contours, high accuracy (6th-8th grades). The allowance should be 0.5-1 mm.

The implementation of each of the stages of processing has its own distinctive requirements for working tools in terms of the nature of their design, material, quantity and quality of cutting edges. For example, a milling fixture with a roughing purpose has coarse teeth, while a fine cutter has a fine multi-tooth structure.

Types of milling work

A wide range of existing milling cutters allows for the processing of materials of varying complexity and configuration, at any angle. All types of processes can be divided into several groups:

- Working with flat surfaces. Roughing and finishing cleaning of non-volumetric planes with a horizontal, vertical or inclined position is performed.

- Processing of bulk shaped blanks and parts. Volume cleaning is carried out, giving objects a certain shape.

- Separation. The parts are divided into several parts, cutting off excess material.

- Modular finish. Based on the formation of the required profile of the existing workpiece, the design of grooves, grooves, teeth, shaped recesses.

A separate milling fixture is most often used for each individual method. Workpieces of particular complexity are processed using a set of cutters. So, milling of wide surfaces is carried out using a set of tools that havemultidirectional helical teeth to reduce axial forces.

Varieties of cutters depending on the purpose

There are several classification features according to which all known milling devices are distributed: by material, by type of knives, by shape, depending on the direction of the working stroke. The main parameter is still the destination.

- Cylindrical - milling of all horizontal and vertical planes.

- End - finishing of all planes in any position.

- End - work of varying complexity, the possibility of flat, shaped, modular, artistic milling.

- Angular and shaped - removing chips from the side surfaces of workpieces, profile objects, cleaning cone-shaped recesses.

- Cut off, slit, spline - parting, cutting teeth on workpieces, grooving.

The same type of tools may have differences in diameter, number of knives and their features.

Design differences between cutters

Characteristics of knives and how they are fixed are important parameters that determine the purpose of the cutter, in particular, the quality of the processing.

- Whole. They are made of tool alloyed and high-speed steels. Most often - cylindrical, disk, slotted, cut-off cutters.

- Compound. There are two options. In the first shank outstructural steel is welded to the cutting head - from tool, high-speed steel, less often - from hard alloy. In the second, high-speed or hard-alloy knives are soldered onto the fixture body. Used in end mills and end mills.

- Teams. Knives, most often carbide, are mechanically connected to the main body.

Solid cutters have more teeth for more precise machining. The same possibility is available for composite tools consisting of a carbide head and a structural shank. Their disadvantage is a high degree of wear. Most often, this equipment is involved in the semi-finishing and finishing stages of chip removal.

Combined cutters are characterized by a high degree of wear resistance, strength, hardness and sharpness of knives, ease of turning and dismantling. However, quantitatively, in the ratio per head, they lose significantly. These are mainly used in roughing.

Machines

The milling jobs that need to be done determine the equipment needed, including the type of machine they will be done on.

Horizontal milling machines are designed for processing horizontal planes and shaped surfaces, manufacturing gears, and decorating some profile objects. Their device determines the horizontal mounting of the tool, most often a cylindrical, disk or end mill.

The same types of work, but with distinctive features, allowsperform a vertical milling machine. A special feature is the vertical clamping of the tool and, therefore, the predominant use of face, end and modular cutters.

Universal milling machines have additional devices for turning the table in 3 planes, which allows you to work with horizontal, vertical and shaped surfaces.

In serial production of parts with the same profile, copy milling machines are used to make repeating patterns or depressions on a plane with increased accuracy.

CNC machines are the equipment of the future. They provide the execution of a programmed set of actions, mainly for artistic milling or non-serial production of parts. End mills, end mills and modular cutters with different number of cutting edges are used.

Milling is work on a special cutting machine that provides the tool travel and feed of the workpiece.

Influence of cutting conditions on the results of work

Results are determined not only by rationally selected equipment. Their quality depends on how well the milling modes are chosen.

- It is necessary to accurately determine the required diameter of the cutter, its design, material, number of teeth, establish the relationship between the dimensions of the tool and the thickness of the layer to be removed. It is important for a professional to strive to ensure that the required thickness of the metal is removed in one pass.

- The size of the tool determines the set speed of its rotation and, accordingly, the speed of work. They are set on the machine by setting the spindle speed - the fundamental axis for fixing the cutter. Too slow or too fast basic working movements of the cutting head will result in a poor quality finish.

- Feed is an important cutting mode. There is a division in this integral concept. Initially, the cutter feed per tooth is determined. It is selected from reference books in accordance with the tool used and the type of work surface. After that, the feed per revolution and per minute are determined, respectively.

The calculation of milling is based on information about the permissible power of the equipment, the type of surface to be machined and the selected tools. There are nominal tables filled with required and control values. Rational selection and calculation of the main parameters of the work determines its quality.

Accompanying phenomena

Milling is a chip removal process that is characterized by increased thermal effects and mechanical stresses that can adversely affect tool performance and finish. Some phenomena that affect the results of milling work:

- Sticking and shrinkage of chips. Sticking of metal on the cutting surface, pressing it spoils the finishing process and the knives themselves. This is more true for soft materials.

- Rolling. Increasing hardness, reducingstrength and plasticity of the surface layer of the part - a side effect of plastic deformation, removed by subsequent heat treatment.

- Friction, increased heat in the work area, vibration are factors that reduce the performance of the cutter.

To prevent side effects, additional technologies and tools must be used.

Protecting workpieces and tools

To avoid or minimize the negative effects of cutting processes on the tool and the material being processed, the following techniques are used:

- The use of coolants and lubricants and liquids, supplying them directly to the milling area reduces friction, hardening, chip adhesion, and maintains a long service life of knives.

- The provided chip removal system eliminates the effect of shrinkage, and the rational selection of cutting conditions for especially soft metals prevents chip sticking.

- Vibrations can be reduced by selecting the front and rear corners of the cutting edges, the desired speeds and the use of vibration dampers.

Milling with minimal side processes requires high professionalism and experience.

Milling is a complex complex process of finishing various surfaces, the success of which is determined by the rational choice of equipment, tools, cutting conditions, lubricants and coolants and accessories that improve the quality of work.

Recommended:

Customs fees and customs duties: types, description, calculation and accounting procedure

What is this? Import and export groups. Classification by purpose of collection, objects of taxation, method of calculation, nature and state of origin. What is special duty? How are these payments calculated?

Cutting speed for milling, turning and other types of mechanical processing of parts

Calculation of cutting conditions is the most important step in the manufacture of any part. It is very important that the calculation itself be rational. This is due to the fact that for various mechanical operations it is necessary to individually select the cutting speed, spindle speed, feed rate, and also the depth of cut. A rational mode is one in which production costs will be minimal, and the quality of the resulting product will be as accurate as possible

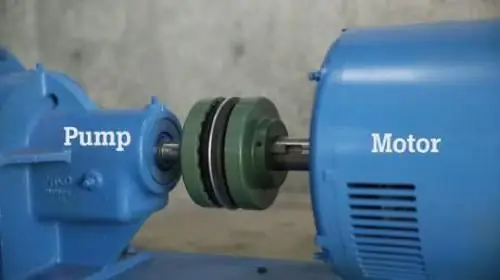

Shaft alignment of electrical machines: features, fixture and device

Misalignment of machine rotors is a common defect that can be corrected. To do this, it is necessary to know the factors affecting it and the methods of shaft alignment. Shaft alignment is usually carried out by concentric and parallel installation of the end surfaces of the coupling halves using special devices

How to transfer a pension when changing residence: necessary documents, procedure and description of the procedure

Despite the fact that older people are very skeptical about changing their permanent address, sometimes they do move. In this case, it does not matter at all what the reason for the change in dislocation was connected with. The main thing is that in such situations a lot of new problems and issues related to them arise

Milling machining center: types, description and purpose

Today, a milling machining center is a multi-operation machine with numerical software. The main advantage is the ability to carry out complex machining of three-dimensional parts. For this purpose, the center is equipped with various processing devices