2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:37

Solar batteries are beginning to gain popularity among the population. They are installed on the roofs of houses, vehicles. Some of them have even been adapted for electronics, in wristwatches. At the moment, they have become a full-fledged alternative to electrical energy or act as a supplement.

How do they work?

Solar modules are the most important element in a photovoltaic system. They are a panel that includes solar cells made of silicon.

To generate electricity, all these components are assembled into blocks, which are then covered with a laminated film - this is necessary for sealing. After that, everything is placed in the frame. The device is quite simple, but it will be problematic to assemble it at home. It is impossible to assemble a photovoltaic cell by yourself, which cannot be said about the panel.

Views

Solar batteries are divided into several types. Three of them can be distinguished:

- Monocrystalline. In the process of its manufacture, a material in the form of pure silicon is used. This basis allows you to get more efficiency from work. The efficiency in this case varies from 15 to 20%.

- Amorphous silicon. At the time of production, a system is used - the evaporation phase. Silicon is covered with a protective layer. A number of advantages of silicon solar cells include an acceptable cost, which is obtained due to the simple technology used in production. Such systems are large in area. Efficiency varies from 5% to 8%.

- Polycrystalline. This solar cell is produced on an amorphous silicon basis. It is not stretched during the manufacturing process. Has a low cost. It can be used not only in everyday life, but also in industry. The efficiency is between 10 and 14%.

Pros and cons of solar panels

Solar panels are made up of photovoltaic cells that convert energy from the sun into electricity during operation.

Some of the benefits include the following points:

- The whole design of the battery is quite simple, there are no moving parts in it. Work is carried out stably and without interruption, the level of reliability is high.

- Installation work is not difficult. No costly system maintenance required.

- Energy from the sun is immediately converted into electricity, no additional time is required.

- Energy is generated throughout the day as long as the sun is present. In some cases, it is possible to receive electricity during cloudy times, but the efficiency of work will decrease.

- The service life is long, it is measured not in years, but in tens of years.

- The production process uses environmentally friendly materials, which is considered very important in today's society, where there is a difficult environment with the environment.

Despite all the advantages, there may be negative aspects in the work:

- Silicon-based semiconductors are expensive. This material is considered the main element in the entire system. It affects both the cost of the panel itself and the cost of the energy received.

- Efficiency is low. To date, the battery power per 1 square is approximately 120 watts. This indicator is so insignificant that it is completely impossible to use the received electricity for lighting fixtures in a small room.

- Getting electricity depends on the length of daylight hours, weather conditions and seasons. For example, in winter, the level of energy received is significantly reduced. This is due to overcast skies, fogs and short daylight hours.

Where can I use it?

These panels are widely used not only in everyday life, in the process of life, but also in industry and production:

- they charge household batterieselectrical appliances;

- electric car charging in progress;

- they can be used to provide electricity to entire buildings;

- in some cases it is possible to use in certain localities;

- you can get energy from them even in space.

All the energy that is generated during daylight hours is stored in batteries, after which the devices can work even in the dark.

What is the principle of operation and device?

Solar cells work on the same principle as when they were first developed. This principle is familiar to everyone, as it was studied in the school curriculum, conducting physical experiments. The transistor, which had no top cover, allowed light to enter the p and n junctions.

After the voltmeter was connected, it could be seen that a small amount of energy was released at the moment the sun's rays hit. Previously, scientists conducted experiments at work, increased the area for transitions. As a result, solar panels appeared.

The design of the solar system of elements contains:

- Surface made of transparent glass. It is on her that the rays of the sun fall.

- Glasses are attached to the rigid edges of the panel. They are plates made of metal, while simultaneously acting as positive electrodes.

- Solar chemical element. Silicon type p.

- Silicon type n.

- Bottom substratemade of metal, which is designed to act as negative electrodes.

It is worth knowing that energy from the sun cannot be received throughout the day. Batteries are not capable of functioning at night. In winter, daylight hours are reduced. At such moments, the main device needs an addition in the form of an energy storage device.

In most cases, an electric battery is used. It is connected to the panel and stores the generated energy, resulting in work in the evening.

The level of efficiency depends entirely on the material used. For example, when using single-crystal silicon, it is almost 20%, polycrystalline silicon reduces this figure by 10%. The level of efficiency can be affected by the smoothness of the surface, the temperature of the air, the location of the batteries to the sun.

What is the relevance of use?

Today, the use of environmentally friendly materials is the most relevant. Electricity, which is obtained at power plants - nuclear, water, thermal, is constantly becoming more expensive. This is due to expensive production. The moment a solar battery is used, a person can rightfully consider himself independent, even from a state that offers electricity for use at an inflated cost.

If you spend a certain amount of money once, you can completely forget about utility bills, meters, utilities. At the moment when these panels are installed, the entire house is being translated. This includes notonly light, but also heating, plumbing - hot water.

Sunshine is an excellent source of electricity. And most importantly, this source is free, environmentally friendly and inexhaustible.

Steps in the production of elements based on a single crystal

Most solar cells are made using polycrystalline and monocrystalline silicon. The production process requires a lot of time, effort and money.

The main production steps for monocrystalline silicon are:

- Silicon production. In order to obtain silicon, quartz sand is used, which contains a large amount of silicon dioxide. Such sand goes through several stages of purification, which allows you to completely eliminate oxygen. This is due to melting at high temperature using chemicals.

- Getting the crystal. After cleaning, the silicon becomes transparent. Crystals begin to grow to streamline the structure. The process is as follows: silicon pieces are placed in a crucible, heated and subjected to melting. Crystal samples are added to the molten mass, which are evenly distributed over the entire surface and begin to grow in layers. This process takes a long time, resulting in a large, uniform crystal.

- Processing. This process begins with the measurement and further processing of the crystal to give the desired shape. When exitingfrom the crucible, the crystal has a round shape, which is inconvenient for further use. To use it, it must be in the shape of a square. After the finished material has been processed with steel threads, it is cut into identical plates using a wire. The size of the plates varies from 0.25 to 0.3 centimeters. After that, they are subject to cleaning, checking for defects and the level of energy that can be generated.

- Development of photovoltaic cell. In order for silicon to be able to generate electrical energy, boron with phosphorus is added to it. After treatment, phosphorus is a free electron of type n, and the side with boron does not contain these electrons and is of type p. Thus, a transition appears between the two sides.

- Assembly process. Initially, the plates are connected in a chain, and then - in a block. One plate has an average power of 2 V and 0.6 W of voltage. Battery power depends entirely on the number of cells. The voltage level is obtained from the connection sequence. All elements and modules are connected in parallel to each other. All cells are covered with a special film, transferred to the glass surface and placed in a rectangular frame. After the module is ready, it is tested. After a full check, it is ready for use.

Solar panels can be connected to each other in parallel, in series or in parallel in series. The choice depends entirely on what voltage level you need to get in the process.

Production process of polycrystalline silicon

ProcessThe production of a module based on polycrystalline silicon is carried out in the same way as with single-crystal silicon. The difference is present only in the growth of crystals. There are several methods for this, but at the moment only one has gained popularity - the Siemens process. The whole essence of the method lies in the fact that the silane is initially reduced and free silicon is precipitated. This is carried out by interacting with a special mixture that contains the elements of hydrogen and silane using a temperature regime ranging from 600 to 1350 degrees Celsius.

This is how the manufacturing process of solar cells works.

How to make a solar panel at home?

Many tend to assume that do-it-yourself solar cells are quite difficult to assemble, even almost impossible. In fact, everything is different. It will take a lot of effort, but the process itself is not difficult, as it seems initially. The main difficulty that you may encounter in the process of work is the collection of a solar cell with your own hands. If you manage to create such a mechanism on your own, then you can think not only about refusing to pay for utilities, but also for the implementation of your own business. At the moment, solar panels are very relevant for the sale of energy reproduced by them. Most importantly, payment is made in one of the most stable currencies - the euro. Is the production of solar cells not worth attention?

In order to work with photocells, you need to haveskills and experience in this area. First of all, this concerns soldering, as well as respect for all elements. To work, you need to have a good soldering tool that is suitable for delicate work. It will not work to create single- and polycrystals on your own. For this, you can use ready-made blanks.

Photocells

The first step in the work is to select the necessary photocells. For battery operation, silicon with poly- and monocells can be used. The most important thing is to take into account the level of performance and nuance when working. For example, in monocells, the efficiency is higher, but in polycells, significant energy is lost in cloudy weather.

All cells are divided into classes. There are four of them in total. Grade A has the best quality with no defects. This class is used in the work of solid and large organizations, companies. The performance is high, but the cost will be appropriate.

When the battery is self-produced, class B can be selected. The efficiency is lower than the previous cells, while the cost is significantly different. Some organizations use this class when manufacturing batteries for sale, which explains the low efficiency.

Some people buy everything they need through online stores. If you go to a specialized store, you can buy all the components at once. Then you won't have to wait for delivery.

Sets

To collect a solar cell, cells alone will not be enough, since they must somehowconnect with each other according to the scheme. This will require the use of conductors and additional materials. That is why some manufacturers offer a ready-made kit for purchase, where all the material that will be needed when working is already present.

This set can include up to 72 elements, conductors, tires, diodes for the circuit, as well as a pencil, which includes a special acid for soldering.

Some kits may contain ready-made photocells to which conductors are soldered. To collect, it will be enough just to collect everything according to the scheme and connect. This option is the most optimal when the solar cells for assembling solar panels are connected manually. The material is very small and fragile, which causes a number of problems in the process.

Soldering

In the event that all the material - elements and conductors - were purchased separately, then the entire process of soldering solar cells will look like this:

- Conductors are cut to the desired length. It is best to do this work according to the template.

- The conductors are neatly placed on the photocell.

- Acid and solder are applied to the place of soldering. To avoid displacement, you can put a heavy object on one end.

- The conductor needs to be soldered carefully. Since the cells are quite fragile, it is not recommended to act on them by force.

Such work is very painstaking, it is not a fact that everything will be done correctly the first time, it may be necessary to repeat the whole process several times. If you study the rules, you can understandthat the deposition of silver conductors is designed for three soldering cycles. There are cases when solder is pre-applied on the conductors, which the manufacturer immediately warns about. But it is best to apply it additionally. During operation, it is forbidden to stack solar cells on top of each other, as they can be damaged due to high pressure.

Sealing

The final stage of work is the sealing of all elements. But before proceeding with this, you need to pay attention to the reliability of the soldering. For this, a multimeter is used. The check can be carried out after the completion of all work or during the entire process, after soldering each individual element.

Silicon sealant is often used for the sealing process. First of all, it is applied to the joints of the elements, and then to the entire panel surface. For such work, you can use a brush, but you need to use it only for joints, since it is possible to easily move the cells from their place. After everything is dry, you can close the lid.

Selecting a battery in the house

At the moment, you can find batteries with two types of solar cells: monocrystalline, polycrystalline.

Each type has pros and cons in operation, which you need to know in advance, before making a purchase.

Market and production opportunities do not stand still, new products regularly appear, in the manufacturing process of which various technologies are used. Before making a choice, it is recommended to pay attention to the characteristicssolar cells: on the level of efficiency, on the presence of a battery that is able to accumulate energy during daylight hours and produce it at night. All these data are provided in advance by the manufacturer, they can be found in a specialized store. It is best to first find information on the Internet or discuss with specialists which option would be best.

Recommended:

Solar-powered lamp: the principle of operation. Types of solar lamps

During the landscaping of the garden, lighting is required in some areas. Lamps can be installed at the main entrance, near gazebos, paths. They are also used as decoration of the site. Connecting lamps to the network is inconvenient, and besides, it is not cheap. Therefore, a solar-powered lamp would be the best choice. The principle of operation of such devices is described in the article

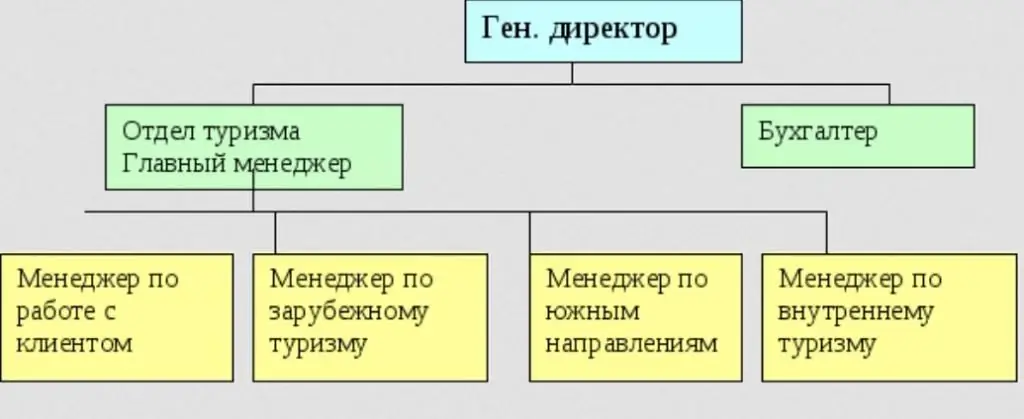

Types of tour operators and their characteristics. Functions and features of the activities of tour operators

The tour operator provides a wide range of travel services and simplifies the reservation of services in other cities and countries, taking on these tasks. In the field of tourism services, it occupies a special niche. In the article we will consider the types of activities of tour operators

Solar energy in Russia: technologies and prospects. Large solar power plants in Russia

For many years, humanity has been concerned about obtaining cheap energy from alternative renewable resources. Wind energy, ocean wave tides, geothermal waters - all this is being considered for additional electricity generation. The most promising renewable source is solar energy. Despite a number of shortcomings in this area, solar energy in Russia is gaining momentum

Fuel cells: types, principle of operation and features

Fuel cells are alternative energy technologies that generate electrical energy from a reaction between a hydrogen-rich fuel source and oxygen. These devices are of particular interest due to their high efficiency compared to traditional internal combustion engines and low emissions

Non-ferrous, precious and ferrous types of metals and their characteristics

Metals are a large group of simple elements with characteristic features such as high thermal and electrical conductivity, positive temperature coefficient and more. To properly classify and understand what's what, you need to deal with all the nuances. Let's try with you to consider such basic types of metals as ferrous, non-ferrous, precious, as well as alloys. This is quite an extensive and complex topic, but we will try to put everything on the shelves