2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:37

It can be seen that over the past decade, products with the prefix "bio" added to the name are gaining popularity. It is intended to inform that the product is safe for humans and nature. It is actively promoted by the media. It even came to the ridiculous - when choosing a drink, they consider biokefir to be the best, and biofuel is no longer an alternative to oil, but an environmentally friendly product. And don't forget about bio-extracts that make cosmetics work "miracles".

General information

Now let's get serious. Often, moving along the roads, you can see spontaneous dumps. In addition, there are full-fledged landfills where human waste is stored. It seems to be not bad, but there is one minus - too long decomposition time. There are a large number of ways to fix this - this is the recycling of garbage, and the use of less harmful materials that quickly destroy decomposers. Let's talk about the second case.

There are many points here. Packaging, tires, glass, derivatives of the chemical industry. All of them requireattention. However, there is no specific universal recipe. Therefore, it is necessary to know specifically what and how to ensure the prevention of environmental pollution.

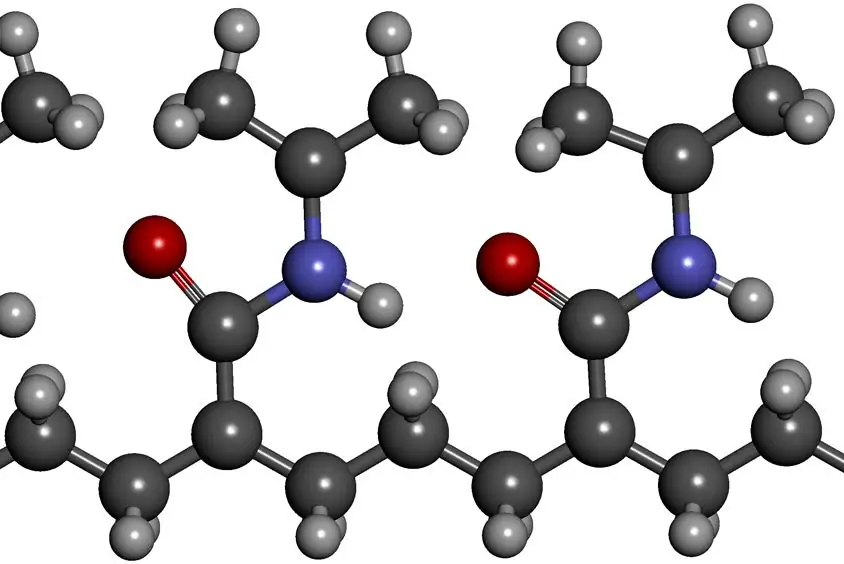

Biodegradable polymers were developed as an answer to the problem of plastic waste disposal. It's no secret that their volume is growing every year. The word biopolymers is also used for their abbreviated designation. What is their peculiarity? They can decompose in the environment due to the action of physical factors and microorganisms - fungi or bacteria. A polymer is considered such if its entire mass is absorbed in water or soil within six months. This partially solves the problem of waste. At the same time, decomposition products are obtained - water and carbon dioxide. If there is anything else, then it needs to be investigated for safety and the presence of toxic substances. They can also be recycled by most standard plastic manufacturing techniques such as extrusion, blow molding, thermoforming and injection molding.

Which areas are being worked on?

Obtaining biodegradable polymers is a rather laborious task. The development of technologies that make it possible to obtain safe materials is actively carried out in the USA, on the European continent, in Japan, Korea and China. Unfortunately, it should be noted that in Russia the results are unsatisfactory. Creating a technology for the biodegradation of plastics and their production from renewable raw materials is an expensive pleasure. In addition, the country still has enough oil for the production of polymers. But everythingsame, three main directions can be distinguished:

- Production of biodegradable polyesters based on hydroxycarboxylic acids.

- Creating plastics based on reproducible natural ingredients.

- Industrial polymers become biodegradable.

But what about in practice? Let's take a closer look at how biodegradable polymers are produced.

Bacterial polyhydroxyalkanoates

Microorganisms often grow in environments where nutrient carbons are available. In this case, there is a deficiency of phosphorus or nitrogen. In such cases, microorganisms synthesize and accumulate polyhydroxyalkanoates. They serve as a reserve of carbons (food stores) and energy. If necessary, they can decompose polyhydroxyalkanoates. This property is used for the industrial production of materials of this group. The most important for us are polyhydroxy butyrate and polyhydroxy valerate. Thus, these plastics are biodegradable. At the same time, they are aliphatic polyesters resistant to ultraviolet radiation.

It should be noted that although they have sufficient stability in the aquatic environment, the sea, soil, composting and recycling environments contribute to their biological degradation. And it happens pretty quickly. For example, if the compost has a humidity of 85% and 20-60 degrees Celsius, then decomposition into carbon dioxide and water will take 7-10 weeks. Where are polyhydroxyalkanoates used?

Theyare used for the manufacture of biodegradable packaging and nonwoven materials, disposable wipes, fibers and films, personal care products, water-repellent coatings for cardboard and paper. As a rule, they can pass oxygen, are resistant to aggressive chemicals, have relative thermal stability, and have strength comparable to polypropylene.

Speaking about the disadvantages of biodegradable polymers, it should be noted that they are very expensive. An example is Biopol. It costs 8-10 times more than traditional plastic. Therefore, it is used only in medicine, for packaging some perfumes and personal care products. More popular among polyhydroxyalkanoates is mirel, obtained from saccharified cornstarch. Its advantage is relatively low cost. But, nevertheless, its price is still twice that of traditional low-density polyethylene. At the same time, raw materials account for 60% of the cost. And the main efforts are aimed at finding its cheap counterparts. The prospect in question is the starch of cereals like wheat, rye, barley.

Polylactic acid

The production of biodegradable polymers for packaging is also carried out using polylactide. It is also polylactic acid. What does he represent? It is a linear aliphatic polyester, a condensation product of lactic acid. It is a monomer from which polylactide is artificially synthesized by bacteria. It should be noted that its production with the help of bacteria is easier than the traditional method. After all, polylactides are created by bacteria from available sugars in a technologically simple process. The polymer itself is a mixture of two optical isomers with the same composition.

The resulting substance has a fairly high thermal stability. So, vitrification occurs at a temperature of 90 degrees Celsius, while melting occurs at 210-220 Celsius. Also, polylactide is UV resistant, slightly flammable, and if it burns, then with a small amount of smoke. It can be processed using all methods that are suitable for thermoplastics. Products obtained from polylactide have high rigidity, gloss, and are transparent. They are used to make plates, trays, film, fiber, implants (this is how biodegradable polymers are used in medicine), packaging for cosmetics and food products, bottles for water, juice, milk (but not carbonated drinks, because the material passes carbon dioxide). As well as fabrics, toys, cell phone cases and computer mice. As you can see, the use of biodegradable polymers is very extensive. And that's just for one of their groups!

Production and biodegradation of polylactic acid

For the first time, a patent for its production was issued back in 1954. But the commercialization of this bioplastic began only at the beginning of the 21st century - in 2002. Despite this, there are already a large number of companies that are engaged in its manufacture - only in Europe there are more than 30 of them. An important advantagepolylactic acid is relatively low cost - it already competes almost on equal terms with polypropylene and polyethylene. It is assumed that as early as 2020, polylactide will be able to start pushing them out on the world market. To increase its biodegradability, starch is often added to it. This also has a positive effect on the price of the product. True, the mixtures obtained are rather fragile, and plasticizers, such as sorbitol or glycerin, have to be added to them in order to make the final product more elastic. An alternative solution to the problem is to create an alloy with other degradable polyesters.

Polylactic acid decomposes in two steps. First, the ester groups are hydrolyzed with water, resulting in the formation of lactic acid and a few other molecules. Then they decompose in a certain environment with the help of microbes. Polylactides undergo this process in 20-90 days, after which only carbon dioxide and water remain.

Starch modification

When natural raw materials are used, it is good, because the resources for it are constantly renewed, so they are practically unlimited. Starch has gained the widest popularity in this regard. But it has a drawback - it has an increased ability to absorb moisture. But this can be avoided if you notice part of the hydroxyl groups on the ester.

Chemical treatment allows you to create additional bonds between the parts of the polymer, which helps to increase heat resistance, stabilityto acids and shear force. The result, modified starch, is used as a biodegradable plastic. It decomposes at 30 degrees in compost in two months, making it highly environmentally friendly.

To reduce the cost of the material, crude starch is used, which is mixed with talc and polyvinyl alcohol. It can be produced using the same equipment as for ordinary plastic. The modified starch can also be dyed and printed using conventional techniques.

Please note that this material is anti-static in nature. The disadvantage of starch is that its physical properties are generally inferior to petrochemically produced resins. That is, polypropylene, as well as high and low pressure polyethylene. And yet, it is applied and sold on the market. So, it is used to make pallets for food products, agricultural films, packaging materials, cutlery, as well as nets for fruits and vegetables.

Using other natural polymers

This is a relatively new topic - biodegradable polymers. Rational nature management contributes to new discoveries in this area. So in the production of biodegradable plastics, many other natural polysaccharides are used: chitin, chitosan, cellulose. And not only separately, but also in combination. For example, from chitosan, microcellulose fiber and gelatin, a film with increased strength is obtained. And if you bury it in the ground, then it will quicklybroken down by microorganisms. It can be used for packaging, trays and similar items.

In addition, combinations of cellulose with dicarboxylic anhydrides and epoxy compounds are quite common. Their strength is that they decompose in four weeks. Bottles, films for mulching, disposable tableware are made from the resulting material. Their creation and production is actively growing every year.

Biodegradability of industrial polymers

This problem is quite relevant. Biodegradable polymers, examples of which have been cited above for reactions with the environment, will not last even a year in the environment. Whereas industrial materials can pollute it for decades and even centuries. All this applies to polyethylene, polypropylene, polyvinyl chloride, polystyrene, polyethylene terephthalate. Therefore, reducing the time of their degradation is an important task.

To achieve this result, there are several possible solutions. One of the most common methods is the introduction of special additives into the polymer molecule. And in heat or in the light, the process of their decomposition is accelerated. This is suitable for disposable tableware, bottles, packaging and agricultural films, bags. But, alas, there are also problems.

The first is that the additives must be used in traditional ways - molding, casting, extrusion. In this case, polymers should not decompose, although they are subjected to temperatureprocessing. In addition, additives should not accelerate the decomposition of polymers in the light, and also allow the possibility of long-term use under it. That is, it is necessary to make sure that the degradation process starts at a certain moment. It is very difficult. The technological process involves the addition of 1-8% additives (for example, the previously discussed starch is introduced) as part of a small typical processing method, when the heating of the raw material does not exceed 12 minutes. But at the same time, it is necessary to ensure that they are evenly distributed throughout the polymer mass. All this makes it possible to keep the degradation period in the range from nine months to five years.

Prospects for development

Although the use of biodegradable polymers is gaining momentum, they now make up a measly percentage of the total market. But, nevertheless, they still found quite a wide application and are becoming more and more popular. Already now they are quite well entrenched in the niche of food packaging. In addition, biodegradable polymers are widely used for disposable bottles, cups, plates, bowls and trays. They have also established themselves on the market in the form of bags for the collection and subsequent composting of food waste, bags for supermarkets, agricultural films and cosmetics. In this case, standard equipment for the production of biodegradable polymers can be used. Due to their advantages (resistance to degradation under normal conditions, low barrier to water vapor and oxygen, no problems with waste disposal, independence from petrochemical raw materials), they continue to winmarket.

Of the main disadvantages, one should recall the difficulties of large-scale production and the relatively high cost. This problem, to a certain extent, can be solved by large-scale production systems. Improving the technology also makes it possible to obtain more durable and wear-resistant materials. In addition, it should be noted that there is a strong tendency to focus on products with the prefix "eco". This is facilitated by both the media and government and international support programs.

Conservation measures are gradually being tightened, resulting in some traditional plastic products being banned in some countries. For example, packages. They are banned in Bangladesh (after they were found to clog drainage systems and cause major floods twice) and Italy. Gradually comes the realization of the real price that has to be paid for wrong decisions. And understanding that it is necessary to ensure the safety of the environment will lead to more and more restrictions on traditional plastic. Fortunately, there is a demand for the transition to more expensive, but environmentally friendly materials. In addition, research centers in many countries and large private companies are looking for new and cheaper technologies, which is good news.

Conclusion

So we have considered what are biodegradable polymers, methods of production and scope of these materials. There is a constantimprovement and improvement of technologies. So let's hope that in the coming years, the cost of biodegradable polymers will indeed catch up with materials obtained by traditional methods. After that, the transition to safer and more environmentally friendly developments will only be a matter of time.

Recommended:

Restaurant concept: marketing research, development, ready-made concepts with examples, description, menu, design and opening of a concept restaurant

This article will help you understand how to prepare a description of the concept of a restaurant and what you need to consider when developing it. It will also be possible to get acquainted with examples of ready-made concepts that can serve as inspiration for creating the idea of opening a restaurant

Unstructured management: description of the concept, methods and methods

General description of the concept of structureless methods of managing people. How do they differ from the structural way of manipulation. Description of various methods and methods of unstructured management of society. Managing other people through leaders. Bringing illustrative examples of such management

Cement slurry: properties, preparation rules, composition, compliance with GOST requirements, purpose and application

During the drilling process, special solutions are used to flush out cuttings and products from the development of local rock. This operation is necessary to increase the efficiency of the mechanical impact of the drilling rig and to clear the bottom hole. Washing out is carried out using cement slurries, which are prepared using special technologies

Drainage of the soil: concept, purpose, methods and methods of work

Irrigation and drainage of soils are very important measures aimed at improving the conditions for normal growth and development of plants. Most novice farmers do not have questions about high-quality irrigation, but not everyone knows what drainage is. So why do you need to drain the soil, in what cases to do it, how to properly carry out this procedure and what it will give

Inorganic polymers: examples and applications

In nature, there are organoelement, organic and inorganic polymers. Inorganic materials include materials whose main chain is inorganic, and the side branches are not hydrocarbon radicals. Elements of III-VI groups of the periodic system of chemical elements are most prone to the formation of polymers of inorganic origin