2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Chloroacetic acid is acetic acid in which one of the hydrogen atoms in the methyl group is replaced by a free chlorine atom. It is obtained as a result of the interaction of acetic acid with chlorine.

The main raw material for obtaining is acetic acid. Chloroacetic acid can also be obtained from the hydrolysis of trichlorethylene.

As a result of hydrolysis, a chemically pure product is obtained. However, this method involves the use of pure distilled water without any impurities.

Chloroacetic acid is used to produce various kinds of dyes, drugs, vitamins and various pesticides. It is also used as a surfactant.

When chlorinating acetic acid in the medium of inorganic catalysts (namely acetic anhydride, sulfur and phosphorus), chloroacetic acid is obtained, the formula of which is CH2Cl-COOH:

CH3-COOH+Cl2↑→=> CH2Cl- COOH+HCl.

Physical properties

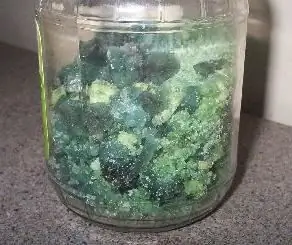

Chloroacetic acid is a hygroscopic, transparent crystal with a melting point of 61.2°C andboiling point 189.5°C. The substance is easily soluble (both in alcohol and in an aqueous medium, as well as in acetone, benzene and carbon tetrachloride).

Monochloroacetic acid is a poisonous and extremely dangerous substance, which, if swallowed, is quite often fatal. When it comes into contact with the skin, chloroacetic acid causes severe burns that do not heal for a long time.

Inhalation of acid fumes can cause inflammation in the lungs and in the upper and lower airways.

Workers in the production workshops for the production of monochloroacetic acid suffer from impaired sense of smell, chronic rhinopharyngitis, peeling and dry skin.

Also, with prolonged interaction with an aggressive substance, lesions of the epidermis of the skin are observed, expressed as dermatitis in the face, neck, upper and lower extremities, in rare cases - the trunk.

Chloroacetic acid in the human body turns into thiodiacetic acid, which is excreted from the body with feces and urine.

Basic operating precautions:

- it is strictly forbidden to inhale fumes, gas, smoke and dust;

- be sure to use personal protective equipment when performing work related to any contact with acid (impervious overalls, goggles, rubber boots and gloves);

- in case of inhalation of vapors or contact of acid on the skin, immediately seek qualified help innearest medical facility.

The maximum permissible and theoretically safe concentration of chloroacetic acid in the air of a production facility is about one mg/m3.

When transporting acid, it is packed in polymer containers (containers or barrels), cardboard drums, and steel containers. Transportation by any type of covered transport is allowed.

It should be remembered that monochloroacetic acid is flammable and explosive. This substance is highly flammable.

Recommended:

Ferrous sulfate: physical and chemical properties, production, application

Ferrous sulfate is a chemical compound that is extremely common in nature and widely used in various fields of economic activity. There are divalent and trivalent modifications of this substance. The first variety, also called ferrous sulfate, is an inorganic binary non-volatile compound having the formula FeSO4

Chlorogenic acid. Features and biochemical properties

From the point of view of organic chemistry, chlorogenic acid is a depside with caffeine esterified hydroxyl at the third carbon atom of quinic acid. Such a chemical compound is present in many plants, but it is in coffee beans that it is of greatest importance due to their extreme prevalence. They contain about seven percent chlorogenic acid

Tungsten: application, properties and chemical characteristics

Mother nature has enriched mankind with useful chemical elements. Some of them are hidden in its bowels and are contained in relatively small quantities, but their significance is very significant. One of these is tungsten. Its use is due to the special properties

Terephthalic acid: chemical properties, production and applications

Terephthalic acid is a colorless pure crystalline powder obtained during the reaction of liquid-phase oxidation of para-xylene in the presence of cob alt s alts acting as catalysts. The interaction of this substance with various alcohols leads to the formation of chemical compounds of the ether group. Dimethyl terephthalate has the greatest practical application

Citric acid production: preparation, process and product

Citric acid was discovered several hundred years ago, but the history of its full-fledged production at industrial facilities can only be spoken of since 1919. From that moment on, technologists began to apply microbiological processes, the development of which has not stopped to this day. At the same time, modern production of citric acid is heterogeneous and involves different ways of manufacturing the final product