2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Mother nature has enriched mankind with useful chemical elements. Some of them are hidden in its bowels and are contained in relatively small quantities, but their significance is very significant. One of these is tungsten. Its use is due to its special properties.

Origin story

XVIII century - the century of the discovery of the periodic table - became fundamental in the history of this metal.

Previously, the existence of a certain substance, which is part of the mineral rocks, was accepted, which prevented the smelting of the necessary metals from them. For example, obtaining tin was difficult if the ore contained such an element. The melting temperature difference and chemical reactions resulted in the formation of slag foam, which reduced the amount of tin yield.

In the VIII century, the metal was successively discovered by the Swedish scientist Scheele and the Spaniards brothers Eluard. This happened as a result of chemical experiments on the oxidation of mineral rocks - scheelite and wolframite.

Registered in the periodic system of elements in accordance with atomic number 74. A rare refractory metal with an atomicwith a mass of 183.84 is tungsten. Its use is due to unusual properties discovered already during the 20th century.

Where to look?

In terms of the number in the bowels of the earth, it is "sparsely populated" and takes 28th place. It is a component of about 22 different minerals, but only 4 of them are essential for its extraction: scheelite (contains about 80% trioxide), wolframite, ferberite and hubnerite (they contain 75-77% each). The composition of the ores most often contains impurities, in some cases, a parallel "extraction" of such metals as molybdenum, tin, tantalum, etc. is carried out. The largest deposits are in China, Kazakhstan, Canada, the USA, there are also in Russia, Portugal, Uzbekistan.

How do they get it?

Due to the special properties, as well as the low content in the rocks, the technology for obtaining pure tungsten is quite complicated.

- Magnetic separation, electrostatic separation or flotation to enrich ore to 50-60% tungsten oxide concentration.

- Isolation of 99% oxide by chemical reactions with alkaline or acidic reagents and phased purification of the resulting precipitate.

- Metal reduction with carbon or hydrogen, output of the corresponding metal powder.

- Production of ingots or powder sintered briquettes.

One of the important stages in the production of metallurgical products is powder metallurgy. It is based on mixing powdered refractory metals, their pressing and subsequent sintering. In this way, a large number of technologically important alloys are obtained, including tungsten carbide, the application of which is found mainly in the industrial production of cutting tools of increased power and durability.

Physical and chemical properties

Tungsten is a refractory and heavy metal of silver color with a body-centered crystal lattice.

- Melting point - 3422 ˚С.

- Boiling point - 5555 ˚С.

- Density - 19.25 g/cm3.

It is a good conductor of electric current. Doesn't magnetize. Some minerals (such as scheelite) are luminescent.

Resistant to acids, aggressive substances at high temperatures, corrosion and aging. Tungsten also contributes to the deactivation of the influence of negative impurities in steels, the improvement of its heat resistance, corrosion resistance and reliability. The use of such iron-carbon alloys is justified by their manufacturability and wear resistance.

Mechanical and technological properties

Tungsten is a hard, durable metal. Its hardness is 488 HB, tensile strength is 1130-1375 MPa. When cold, it is not plastic. At a temperature of 1600 ˚С, plasticity increases to a state of absolute susceptibility to pressure treatment: forging, rolling, drawing. It is known that 1 kg of this metal makes it possible to produce a thread with a total length of up to 3 km.

Machining is difficult due to excessive hardness andfragility. For drilling, turning, milling, carbide tungsten-cob alt materials are used, made by powder metallurgy. Less often, at low speeds and special conditions, tools made of high-speed alloyed tungsten steel are used. Standard cutting principles are not applicable, as the equipment wears out extremely quickly, and the processed tungsten cracks. The following technologies are applied:

- Chemical treatment and impregnation of the surface layer, including the use of silver for this purpose.

- Heating the surface with the help of furnaces, a gas flame, an electric current of 0.2 A. The permissible temperature at which there is a slight increase in plasticity and, accordingly, cutting improves, is 300-450 ˚С.

- Tungsten cutting with fusible materials.

Sharpening and grinding should be carried out using diamond and elbor tools, less often corundum.

Welding of this refractory metal is carried out mainly under the action of an electric arc, tungsten or carbon electrodes in an inert gas or liquid shielding. Contact welding is also possible.

This particular chemical element has characteristics that make it stand out from the crowd. So, for example, characterized by high heat resistance and wear resistance, it improves the quality and cutting properties of alloyed tungsten-containing steels, and its high melting point makes it possible to produce filaments for light bulbs and electrodes for welding.

Application

Rarity, unusualness and importance determine the widespread use in modern technology of a metal called Tungsten - tungsten. Properties and application justify the high cost and demand. High melting point, hardness, strength, heat resistance and resistance to chemical attack and corrosion, wear resistance and cutting features are its main trump cards. Use cases:

- Filaments.

- Alloying of steels in order to obtain high-speed, wear-resistant, heat-resistant and heat-resistant iron-carbon alloys, which are used for the production of drills and other tools, punches, springs and springs, rails.

- Production of "powdered" hard alloys, mainly used as highly wear-resistant cutting, drilling or pressing tools.

- Electrodes for TIG and contact welding.

- Production of parts for X-ray and radio engineering, various technical lamps.

- Special luminous paints.

- Wire and parts for the chemical industry.

- Various practical small things, for example, jigs for fishing.

Various alloys containing tungsten are gaining popularity. The scope of such materials is sometimes surprising - from heavy engineering to light industry, where fabrics with special properties (for example, fire-resistant) are made.

There are no universal materials. Each known element and created alloys are distinguished by their uniqueness and necessity for certain areas of life and industry. However, some of them have special properties that make previously unfeasible processes possible. One such metal is tungsten. Its application is not wide enough, like steel, but each of the options is extremely useful and necessary for humanity.

Recommended:

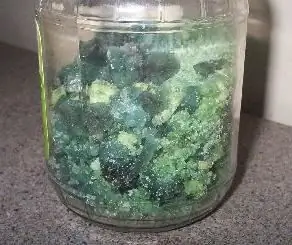

Ferrous sulfate: physical and chemical properties, production, application

Ferrous sulfate is a chemical compound that is extremely common in nature and widely used in various fields of economic activity. There are divalent and trivalent modifications of this substance. The first variety, also called ferrous sulfate, is an inorganic binary non-volatile compound having the formula FeSO4

Green marble: characteristics of properties and application

Today, green marble is widely used in construction and decoration. They veneer buildings, walls and floors of premises, create mosaic compositions and decorative ornaments, make tabletops and window sills, flowerpots. When decorating parks and gardens, fountains, gazebos, and stair railings are covered with such marble. It is used to create monuments, tombstones, monuments

Propylene glycol - what is it? Chemical properties, application

Propylene glycol - what is it? Composition of the molecule, structure, physical and chemical properties of matter. The use of propylene glycol in the industry: food, cosmetics. Application for technical purposes, in medicine

Two-component polyurethane sealant: definition, creation, types and types, characteristics, properties and nuances of application

With long-term and high-quality sealing of seams and cracks, polyurethane two-component sealants have found their wide distribution. They have high deformation and elastic properties, therefore, they can be used as butt sealants in the field of repair and housing construction

Concrete mix: properties, composition, types, grades of concrete, characteristics, compliance with GOST standards and application

Among the main properties of the concrete mixture, which is also called hydrotechnical concrete, it is necessary to highlight the increased water resistance. Buildings are being built from this material to be used in swampy areas or in regions that are prone to flooding