2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-06-01 07:12:56

Forms are printing products. They look something like this: on a sheet of A4 paper (sometimes smaller) the company logo is placed, as well as standard text. The rest of the free space is intended to be filled with content in the future. Forms are produced on special offset, special design paper, different color solutions are used, for example, as on an envelope.

Letterhead is the face of the company. Its formation takes place in the same style as business cards, booklets and other printing materials. Mandatory production of letterheads of the company provides for the placement of the address of the company, its logo on them. They are printed on offset paper, which is matched to the tone of the envelopes. If letters are printed on the forms on a laser printer, only offset printing is used for their production. A stylish letterhead is a balanced and strict design,excluding any unnecessary details. Nothing should distract from reading the letter.

The most common types of forms are:

- Letterhead. They have already been mentioned above, and in addition to the logo and address, they can also contain an application, guarantee, various information, etc. They are used when drawing up documents within the company (decrees, orders), as well as with external contacts. Using them has a positive effect on the image of the company.

- Forms with symbols. The production of forms of this type is carried out in order to use them for external and internal document management. Forms with logos are produced on coated offset or other paper of various shades from 1+0 to 4+4.

- Self-adhesive forms. Here special paper is used. These forms are used to compose various correspondence, label products in warehouses and trading floors, streamline office documentation.

In addition to these types, the production of self-copying forms is also common, which allows you to create the required number of copies of the document when filling out.

Pro Tips

Letterhead making is a whole science, and there are also difficulties and subtleties known only to people in a narrow circle. Often, print industry professionals share their advice, and here are some of them:

- it is recommended to maintain a business style in the forms when making out. This approach emphasizes the solidity and significance of your company;

- the offset method is the most optimal. These forms are suitable for all types of printers.

- light weight paper is the best, it will not create problems when printing text on your company's regular printer;

- To save money, you can reduce the colors to one or two. If the circulation is small, the savings will be tangible. You can also choose the lightest paper, the weight of which is 90 grams. In addition, use the optimal quantities for production.

Postpress processes

Preparation of forms also includes post-press processes. The appearance of your letterhead can be distinguished by embossing, selective UV varnish, hot stamping. In most companies, the production of forms is carried out according to the provided layouts, the client only specifies his individual requirements for them. In addition, according to the wishes of the customer, a completely unique design of the letterhead is being developed.

Recommended:

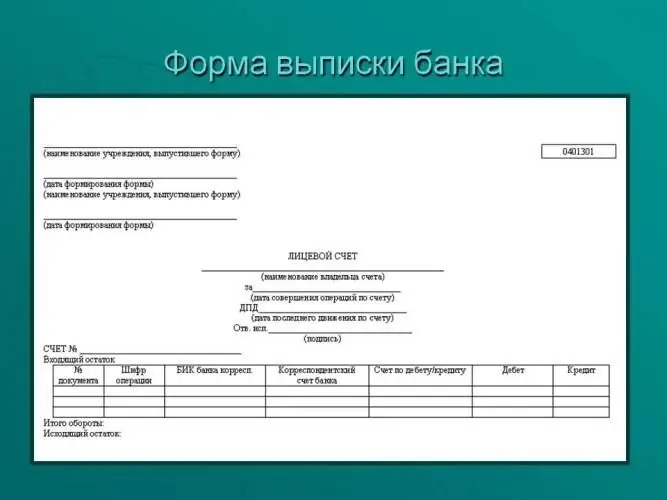

A bank statement is The concept, necessary forms and forms, design examples

When purchasing any banking product, any client, sometimes without knowing it, becomes the owner of an account with which you can carry out income and debit transactions. At the same time, there must certainly be a certain tool that allows any client to exercise control over the movement of their own funds. This is a bank statement. This is a document that is usually issued upon request to the client. However, not everyone is aware of this possibility

Mutual settlements between organizations: drawing up an agreement, necessary documents, forms of forms and rules for filling out with examples

Settlement transactions (offsets and settlements) between business entities are quite common in business practice. The result of these operations is the termination of the mutual rights and obligations of participants in civil relations

Damascus steel - history and manufacture

Damascus steel is one of the most popular steel used to create blades. Products from this alloy are characterized by a unique pattern and excellent cutting properties

Manufacture and installation of metal structures. Production features

Prefabricated buildings are the best option for many businesses, which is why most consumers today prefer steel structures. Production, manufacturing and installation will be carried out by special construction organizations that guarantee high-quality construction of any type of object

Documents for property deduction: general information, required forms and forms

Registration of a property deduction is a procedure that many citizens of the Russian Federation are interested in. This article will show you how to get it. What needs to be prepared? Under what conditions and to what extent can one claim a property type deduction?