2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:39

The desire of a person to shift heavy monotonous work onto the shoulders of machines and mechanisms is directly related to such, at first glance, unfortunate property of psychology as laziness. However, any device should be managed, which, of course, is easier than working on your own, but it can also be difficult.

So there was a science, the name of which comes from two Greek words meaning "self" and "acting". So, automation is a system of knowledge that allows you to make machines work without human intervention. This discipline is studied in technical universities and is reputed to be no less complex among students than the notorious "Termekh". And no wonder, it is impossible to master the theory of automatic control (TAU) without a very good level of training in higher mathematics and physics.

Automation of production can be partial, complex or complete, differing in the degree of detachment of a person from the process of managing technological processes. The main reason for its widespread use is economic feasibility, since the maintenance of technical means is cheaper than that of personnel. However, as shownpractice, the quality of finished products is also higher when the human factor is minimized.

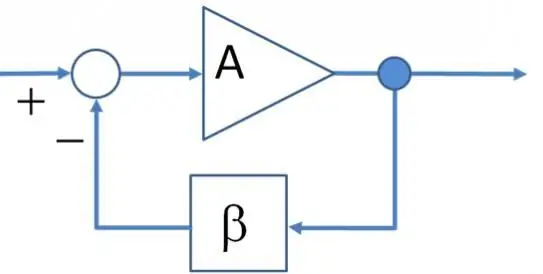

If we consider this theory in a simplified form, it will not seem so complicated, the main thing is to learn its basic concepts. The main term TAU is a control object, that is, a certain device for industrial or domestic purposes, one of the parameters of which should be regulated by automation. This may be, for example, a tank in which the liquid level or its temperature must be maintained with a given accuracy. On the block diagram, it is indicated by the letter "A".

The second device needed to create a control loop is a sensor. Without it, it is impossible to judge the state of the system, that is, the value of the output parameter (in our case, level or temperature). It is marked with a blue circle.

The third device, without which automation is impossible, is the regulator (β). It can be extremely simple (two-position), as in an iron, for example, or complex, representing an electronic unit with settings that provides a special algorithm (proportional, proportional-integral or proportional-integral-differential). The task of the automatic regulator is to generate a control signal supplied to the fourth and last element of the circuit - the actuator (IM). No matter how sophisticated the scheme of the whole system, if its decisions are not carried out, it will not work. MI is indicated by a white circle, and the signs "+" and "-" symbolize the negative nature of the reverseconnection, that is, the opposite of its action to the direction of change of the output parameter.

Practically all process automation in any production works according to this scheme. Despite its apparent simplicity, it is effective, although it requires a thorough study of all the features of control objects. The fact is that they, like people, react differently to disturbing influences (this is how automation specialists call different destabilizing factors). First, they all have a lag time. Secondly, the transfer coefficient, that is, the effectiveness of the impact, also differs for different objects. And the speed of "acceleration" is different for each control channel.

After characterization and installation of control and management elements, the most important stage begins, which completes automation. This is setup and tuning.

Recommended:

What to do without the Internet, what to do? How to have fun without a computer?

We are so used to the Internet that being disconnected from it can become stressful. But there are ways to stay productive offline. Whether you're at home, in the office, or traveling, here are a few ideas of what you can do offline

Automation of control systems: levels, tools, features and applications

Automation of control systems, or ACS for short, is a set of devices that allows you to effectively and semi-automatically or fully automatically monitor the progress of the process. They are most widely used in industry

Where can I get a loan in Omsk without refusal and without references?

Getting a loan in Omsk will not be difficult for any borrower with a positive credit history. But, unfortunately, not everyone has it. Which bank should I contact to get a loan with a bad credit history and without references in Omsk?

Which banks give mortgages without a down payment? Where can I get a mortgage without a down payment?

Many would like to live in their own apartment. But not everyone has the money to make the first payment. Are there any alternatives and which banks give mortgages without a down payment?

Earnings on the Internet without investments in Belarus. How to earn without leaving home?

In this article we will tell you how to find earnings on the Internet without investments in Belarus. We will also select some basic examples of how you can receive money online. Using specific of them, we will understand how to create our own schemes for earning in more detail