2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

Grab bucket is widely used for moving and loading bulk and coarse-grained materials, scrap and wood shavings, as well as long timber. It can be imagined as a large iron scoop, assembled from two identical moving parts, jaws, which is attached to a crane equipment for moving loads or to an excavator to excavate the soil above or below the level of the parking lot. However, its scope is not limited to this.

Grapples capacity

The grapple is most often used as an attachment in excavators and cranes with a mechanical or hydraulic drive. The main parameter characterizing its work is the carrying capacity. Its scooping capacity depends on the ratio of the mass of the load and the bucket itself. Therefore, all materials that are moved using a clamshell bucket are divided into several groups according to their bulk density.

The load capacity of the working equipment is determinedimmediately before the start of work by trial scooping. It is produced from a horizontal platform on which freshly poured soil or material is placed. The seized cargo is poured onto a special surface and weighed. During work, ropes and blocks must be protected from the material to be gripped.

Rope grabs

Grabs, depending on the number of working ropes, are divided into one-two-, four-rope and raking subspecies. The simplest version has a single-rope clamshell bucket. In it, only one cable is responsible for moving the load in a vertical plane and its capture. The main feature of the bucket of this subspecies is the presence of a lock that connects the traverse to the clip. Its main disadvantage is the low lifting height of the material and manual control of the opening of the jaws.

Double-rope grapples have a lifting and locking cable. The latter is necessary for opening and closing the jaws. Such a bucket can be equipped with a chain hoist, in which the closing rope is packed, if it is necessary to increase the cutting force. The main disadvantage is the inability to quickly replace the bucket with other lifting equipment.

The four-rope clamshell bucket has two closing and lifting cables each, which gives them a greater carrying capacity compared to other types. The raking type of working equipment is used for scooping up material in cramped conditions - from wagons, holds. Often the rope system in such a grab forms a horizontally orientedpulley block.

Drive grabs

In the drive grab, a separate mechanism is responsible for closing and opening the jaws, which is fixed on the hook frame with a winch. They have more mass than the rope subtypes, but the unloading control is simpler, and the load capacity is higher.

The volume of a clamshell bucket with a drive mechanism depends on its carrying capacity, which, in turn, is determined by the type of mechanism that closes the jaws. It can be represented by:

- Electric chain hoist.

- Hydraulic cylinders.

- Lever mechanism.

The main advantage of this type of grabs is their small size, which allows them to be used in small areas. The main disadvantage is the displacement of the center of gravity of the bucket, which violates its stability when scooping material from a slope.

Excavator Grabs

Grab buckets for excavators can have a different number of jaws of different shapes. This type of working equipment can be installed on machinery with mechanical and hydraulic drive.

Mechanical drive type excavator for grapple installation must have a lattice dragline boom. The weight of the bucket depends on the density of the developed soil. In accordance with this, light, medium and heavy class equipment is produced. With an increase in the weight of the grab, its productivity decreases, since the excavator can lift less soil.

For developmentdense rocks use hydraulic grab buckets for excavators. As a rule, this equipment is mounted on the "backhoe" technique. Soil cutting is carried out by hydraulic cylinders driven by a special engine.

Magnetic and pneumatic grapples

The design of pneumatic buckets is no different from the design of hydraulic grabs. But such equipment is powered by compressed air, which is injected into the system using a compressor.

The principle of operation of a magnetic grab is based on the occurrence of a magnetic field, which occurs when an electric current is applied to the excitation coils. After the current is applied, the magnet approaches the grab and closes the jaws. As a rule, magnetic grabs have a large bucket, which not only captures bulk materials, but also attracts ferromagnets (iron, steel), which significantly increases the volume of material handled.

Recommended:

Indicators for scalping without redrawing: features, advantages and disadvantages

In trading on the financial markets, there are various methods by which traders earn. Each trading system has its own features and characteristics, and most of them use special tools. In this article, the reader will learn about different types of trading tools, including indicators for "Scalping" without redrawing

Collective investments: concept, types and forms, advantages and disadvantages

Collective investment is a type of trust management with a low entry threshold that allows small investors to invest in the stock market, real estate market, precious metals and others, making a profit from investing their money. This is an investment of the joint capital of investors, which makes it possible to earn money by significantly increasing their capital

Connections: purpose, types of connections. Examples, advantages, disadvantages of types of compounds

Machines and machine tools, equipment and household appliances - all these mechanisms have many details in their design. Their high-quality connection is a guarantee of reliability and safety during work. What types of connections are there? Let's take a closer look at their characteristics, advantages and disadvantages

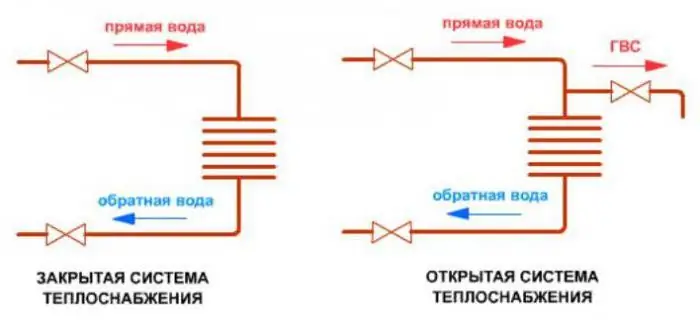

Closed and open heating system: features, disadvantages and advantages

At present, it is promising to introduce the technology of a closed heat supply system for consumers. Hot water supply allows you to improve the quality of the water supplied to the level of drinking water. Although new technologies are resource-saving and reduce air emissions, they require significant investment. Ways of implementation are at the expense of commercial and budgetary financing, competitions for investment projects and other events

Purple tomatoes: types, variety description, cultivation features, care rules, advantages and disadvantages

Recently more and more people are attracted to the exotic. She did not bypass the side and vegetables, and in particular tomatoes. Gardeners are very fond of unusual varieties and are just eager to grow them on their plots. What do we know about purple tomatoes? Are they really that good or is it just a fashion statement? After all, all exotic varieties, as a rule, require special care