2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

Test benches are research equipment designed for various acceptance, control, special tests of technical and mechanical objects. The essence of the test is to identify the correspondence between real and maximum loads. Consider the types of such devices and their features.

General information

Test stands in a standard configuration are a complex consisting of a frame, a vibration, hydraulic or other working system, instrumentation, accessories.

Checking a device or mechanism on a stand allows you to evaluate several parameters at the same time that affect the object. In real conditions, such testing is almost impossible. After testing, indicators are fixed. Violations of the unit operation or its full compliance with the required parameters are determined. This approach allows timely identification and elimination of design flaws.

Assignment and use of test benches

The use of the devices in question contributes to the following aspects:

- Improving product quality.

- Ensures energy savings.

- The influence of the human factor on a number of processes is reduced.

- Improve working conditions by automating and controlling the process.

Typically, there are three main positions available on the test bench:

- Perform design and study of objects.

- Determine the ability to manufacture or repair production samples that need regular inspection or calibration.

- Control the operation of the equipment during operation.

At each stage, a number of tests are provided, which are usually carried out according to standard methods. After the implementation of the conceived algorithm, the automatic system makes it possible to mathematically evaluate several parameters of the controlled object. In turn, this improves the performance, accuracy and economy of the device. Modern test benches have an automated performance matrix that, after a short period of time, displays all readings with a decryption.

Working principle

Automated devices make it possible to use them with minimal operator involvement. For example, to test software and its analogues, a software package is used that can virtually test the required units.

This technology provides a number of advantages, namely:

- Autonomousswitching of measuring channels.

- Power settings remain unchanged.

- Readings are taken automatically, after which they are recorded in the measurement log.

- Test settings are selected in accordance with the conditions and features of the test.

Hardware items

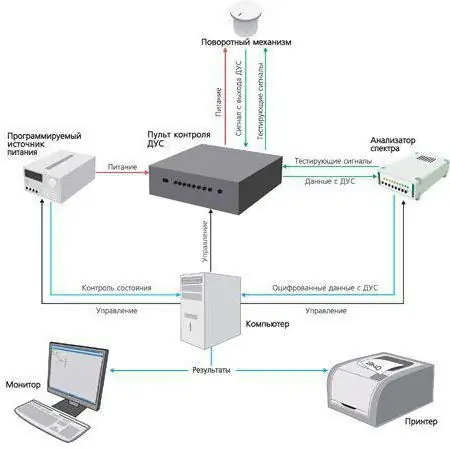

In this regard, the test bench equipment consists of the following fixtures:

- A spectrum analyzer responsible for incoming analog signals of the tested object.

- Amplifiers that are required to improve the incoming information in an impulse form.

- Switching unit. This node allows you to test incoming information using special analyzers, regardless of the communication channel used.

- Power sources used to activate the stand or parts of the device under test.

- Multimeters, boards and converters. They perform the function of stabilizers and normalizers, ensuring normal operation without voltage drops or other factors.

- Additional devices.

Program part

It is worth noting that electrical equipment test benches can combine several parts in one housing. This allows you to simultaneously check almost all the required parameters of the object being examined.

The program of some stands is made in the ZETVIEW system, which involves the use of several block matrices. The equipment in question can be manufactured for a purely narrow specialization.or check the full range of possible aspects.

Universal Test Bench

Such verification machines make it possible to test fixtures that have similar characteristics. The operator simply needs to select the appropriate object from the list and configure the device taking into account the required parameters. Typically, frequency, dynamic ranges, the number of indicators checked and error limits are subject to changes.

Such devices are equipped with a complex interface, which allows the user to adjust the software settings. A similar type of stands are multifunctional modifications. They are designed to work in several modes. Among them:

- Calibration.

- Debug.

- Checking.

To set up the correct functioning of the device, you will need to select the appropriate item. Such devices allow the operator to select the desired program and test the object. After that, if necessary, he can reconfigure the next mode.

Analogues

The hydraulic test bench makes it possible to test the corresponding elements of distributors and amplifiers. As a result, the indications of the power characteristic, the readings of the sensors, the amplitude of the transmitted signal and other basic operating parameters are recorded. The unit consists of control valves that open and close, depending on the direction of the test. With this device, you can test the following indicatorshydraulic devices:

- Pressure supply.

- Kinematic energy.

- Speed aspects.

- The tightness of the device.

- Operation of control devices.

- Functionality of motors and accessories.

Features of hydraulic test stand

The device under consideration refers mainly to the field of mechanical engineering. It can also be used to test hydraulic valves, electro-hydraulic boosters, and other units equipped with a suitable system.

The test stand diagram shown below indicates that the device can also be equipped with a control box. This allows you to test electromechanical transducers. They measure the performance between the amplifier and the output parameter block, as well as the condition of the hydraulic motor.

In the modifications under consideration, the speed indicator is determined by applying currents of different polarity and magnitude to the EMF input. At the same time, the speed of movement of the output part of the technological motor is taken into account, and the amount of travel of the moving link is also controlled.

Cons

The negative features of these units include a very long duration of measurements, especially in the field of low flow rates, which have a low informative content.

However, the advanced hydraulic test bench design allows you to test not only the main motor, but also its related units,as well as an amplifier. Moreover, this can be done with connected hydraulic lines, without draining liquids.

Finally

The price of a test bench depends on many factors. First, the type of device affects the cost. It is logical that modern automated devices will cost much more. However, they are able to display test results for all required parameters directly on the display in seconds.

Used modifications can be purchased from 85 thousand rubles. This applies to the simplest model. More productive options can cost upwards of $5 million. It should be noted that the units under consideration not only provide verification of the objects under examination, but also participate in the guarantee of safety and quality of products. Therefore, test benches are one of the most effective methods for the development and control of existing instruments, devices and mechanisms.

Recommended:

Warehouse program: overview, description, application, types and reviews

One of the effective ways to reduce the costs of the enterprise is to increase the efficiency of the implementation of warehouse tasks. This goal is achieved through process automation. It gives the company a significant advantage in the market

Main types and types of business plans, their classification, structure and application in practice

Each business plan is unique, because it is developed for certain specific conditions. But you need to familiarize yourself with the features of various types of business plans in order to understand their key features. Experts recommend doing this before compiling your own similar document

Perforated metal pipe: types, description and application features

The article is devoted to perforated metal pipes. The features of such products, varieties and scopes of application are considered

Two-component polyurethane sealant: definition, creation, types and types, characteristics, properties and nuances of application

With long-term and high-quality sealing of seams and cracks, polyurethane two-component sealants have found their wide distribution. They have high deformation and elastic properties, therefore, they can be used as butt sealants in the field of repair and housing construction

Dosimetric device DP-5V: description, diagrams and characteristics

The dosimetric device DP-5V was designed for use by the troops. It is intended for use in confrontation conditions, when nuclear weapons are used to conduct reconnaissance of the area for radiation contamination