2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:43

The operating conditions of materials in aggressive environments inevitably force users to think about special protection of target objects and structures. These can be construction, industrial, as well as household technical and other facilities that require resistance to hostile influences. One of the most effective ways to solve this problem is cladding. This is one of the methods of external coating of parts and structures, which in our time is experiencing a new round of development.

Technology overview

The main purpose of cladding is to create a coating on the workpiece surface that could provide the protective functions specified by the project. Among the latter, fire resistance, biological stability, frost resistance, etc. can be mentioned. In some cases, new properties are added, such as insulatingqualities or increase electrical and thermal conductivity. What is cladding in terms of practical implementation?

This is a process of building new technological and functional layers on the surface, which can be done in different ways. We can talk about a direct coating or overlay, but it is the method of formation of layers that has fundamental differences. Classical approaches to cladding involve thermomechanical formation of a protective shell, but today, with the advent of new materials, the methods of structural arrangement of protective coatings are also changing.

Planning Features

It is also possible to form a functional coating on the surface of a conditional product with ordinary paint with one or another set of properties. Cladding, on the other hand, refers to external protection methods that involve intrusion into the structure of the target surface. This effect of the fusion of the functional layer and the base material is just achieved by thermal action, which can be expressed in different forms. For this reason, cladding of metal surfaces is often accompanied by temperature-time welding with subsequent deformation of the workpiece.

Another fundamentally important feature of cladding is its multi-layered nature. The structure is formed not by a homogeneous layer of one or another protective material, but by several heterogeneous layers that have a different functional direction. Moreover, some of the layers may have a general functional purpose (fire resistance, temperature resistance, biosecurity), and the other part performs special tasks within the structure.coating, for example, creates an adhesive base for bonding layers of cladding.

Clading technique

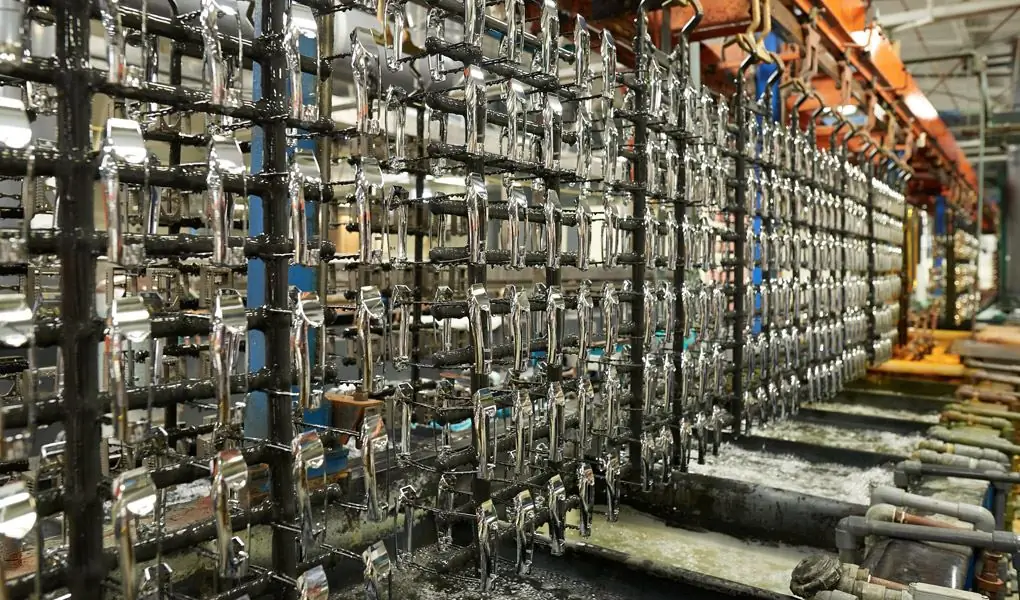

The cladding operation can be performed both in a separate format and as part of the general technological process of production or processing of a part. In both cases, the basic method of implementing the technology involves the layer-by-layer deposition of alloys on the target surface. In the case of metals, this operation is carried out during hot rolling, drawing or pressing. At the stages of seam connection, the cladding technology provides for thermal deformation, which creates conditions for the diffusion of a hot billet.

In this way, entire groups of metals can be superimposed and fused, including steel, copper, aluminum, corrosion-resistant alloys, etc. At the present stage of technology development, it is also practiced to include independent polymer layers and modifiers that improve individual properties applied coating.

Use of cladding tape

In order to optimize the technological process of cladding, the concept of laying the finished multilayer coating was developed. It is represented by a bimetallic strip, which contains in its structure several heterogeneous layers obtained as a result of cold rolling. The basis of this workpiece is made up of both ferrous metals and composite materials, which are used in pure form in machine-building, electrical, food, chemical andother industries.

Low-carbon steel is almost always used as the basis for the tape, thanks to which the main cladding process is carried out - this is a kind of intermediate binder, the melt of which connects the workpiece and the functional coating of the tape. By the way, the differences of multilayer tapes of this type are not limited to the approach to the structural device of the coating and cover the spectrum of tasks of new layers. On the cladding shell, work units and parts such as current-carrying circuits, tips, bimetallic contacts, disconnecting knives, electrical clamps, etc. can initially be placed.

Laser cladding technique

Promising direction of technical implementation of cladding with the principles of gas welding. As a thermal source, a laser beam is used, which ensures the state of the melt of the workpiece and the active material. The raw material for laser cladding is usually powder, which can be compared to the flux used in gas welding. This is the basis of the melt, which forms a thin functional layer as a result of laser exposure. As for gas mixtures, their supply plays an auxiliary role in protecting the working area from the negative effects of oxygen.

Powder cladding

Loose mixtures of chromium, tungsten and nickel can also be considered as an independent basis for cladding, not necessarily associated with laser melt technology. Combined powder mixtures specially selected fora certain set of functions are applied to the metal by chemical cladding. This is a particle transport reaction in an alkali-based ionic melt.

Directly, the process of coating with molten powder takes 30-40 minutes at a temperature of about 700°C. The complexity of this technology in production conditions lies in the need to connect large specialized equipment with crucibles and high-temperature furnaces.

Restoration of the cladding layer

Like many other types of coatings, the cladding base collapses over time, requiring restoration or repair. Partial correction of multilayer coatings is carried out by means of gas-thermal, electro-thermal or plasma spraying. The basis for spraying can be the same flux made of composite materials or metal alloys. Wet-recovery cladding is also becoming more widespread.

These are special formulations that contain ultrafine or soluble metals, their compounds or alloys. After application under the influence of certain temperatures or chemical reactions, the solution polymerizes, and after a few hours the updated coating can be put into full operation.

Conclusion

In many areas of the national economy, industry and construction, a special modification of the materials used is required, however, due to economic and organizational conditionsnot all ways to improve the characteristics of the target workpiece can be used. Modern cladding methods also remain inaccessible to many potential consumers due to the high cost and technological complexity of their implementation.

On the other hand, the example of a multi-layer tape shows that it is quite possible to simultaneously improve the performance of the coating and simplify the process of its formation on the surface of the final product. However, such innovations are still found only in certain industries related to the production of electrical products.

Recommended:

Benefits when buying an apartment: types of benefits, government assistance, tax calculation and legal advice

The statistics in our country are disappointing: every second Russian has problems with housing. Some people save half their lives, others take out mortgages, others get in line for social programs. But people in any category will not forego benefits at the time of the transaction because they want to save money. So what are benefits and who do they apply to?

Stock beekeeping: technology, benefits, efficiency

Once upon a time, our ancestors were engaged in deck beekeeping. However, some still prefer to use this type of farming. It should be noted that such beekeeping is the most optimal for beginners in this business. Let's take a closer look at its features, as well as recommendations for managing such a farm

Diamond drilling technology and key benefits

Every year, diamond drilling and concrete drilling are replacing other technologies. For example, a puncher has many disadvantages, unlike this method. These are vibrations, high noise levels, etc. Most often, such drilling is used during construction or repair work. Let's talk about this topic and see what are the pros and cons of diamond drilling

Types, features of installation and application of equipment for chromium plating

The article is devoted to chromium plating equipment. The features of this equipment, chrome plating technique, etc. are considered

Chemical nickel plating - features, technology and recommendations

Technologies for metallization of parts and structures are widespread in various areas of industry and construction. An additional coating protects the surface from external damage and factors that contribute to the complete destruction of the material. One of such treatment methods is chemical nickel plating, the strong film of which is distinguished by mechanical and corrosion resistance and the ability to withstand temperatures of the order of 400°C